2.6

Maintenance

BREAK-IN PROCEDURES

Engine Break-In Procedure

The first tank of fuel is considered the break-in period for

the engine. During this time it is critical to not operate the

engine at full throttle for more than a few seconds. Vary the

throttle speed as much as possible. Monitor engine

temperatures and fluid levels often during the break-in

period.

NOTE: During the engine break-in period, verify the

oil inject

ion system is functioning by monitoring the

oil level in the oil tank. If the oil level does not drop,

inspect the oil injection system.

Polaris recommends filling the oil t

ank and pre-mixing the

first full tank of fuel with Premium 2-Cycle Semi-Synthetic

Oil when the engine is either new or refurbished (new

pistons, crankshaft, cylinder, etc.). Polaris semi-synthetic

engine oil will seat the rings faster than when using Polaris

VES Gold Plus oil.

After the break-in period use Polaris VES Gold P

lus

engine oil for normal operation.

Fuel/Oil Premix Ratio

During the break-in period, premix the first tank a fuel (10

US gallons) using a 40:1 (fuel:oil) ratio.

Formula = 1 US Gallon = 128 oz. / 40 (Desired Ratio) =

3

.2 oz. for every 1 US gallon of fuel.

10 US gallons of fuel require 32 oz. of oil to achieve a 40:1

p

remix ratio.

Always mix fuel and oil 5 gallons at a time. Never fill the

t

ank with fuel and then add oil.

Drive Belt Break-In Procedure

The break-in period for a new drive belt is 30 miles. During

this time, vary the throttle position under 50% and limit full

throttle use.

New drive belts that feature a sanded finish should be first

washed with

warm, soapy water and allowed to air dry

prior to use.

Always take time to warm up the

belt and driveline prior to

operating the snowmobile. Free track and skis from the

ground before engaging throttle.

ENGINE MAINTENANCE

Variable Exhaust Valve Cleaning

The exhaust valve guillotines must be cleaned to ensure

maximum engine performance and throttle response.

1. Remove the vent hose f

rom the EV base fitting.

2. On the MAG VES assembly, remove the two

fa

steners that secure the valve assembly to the

cylinder. Remove the cover after the assembly is

removed from the engine.

3. On the PTO VES assembly, remove all four screws.

Re

move the cover and spring from the EV base.

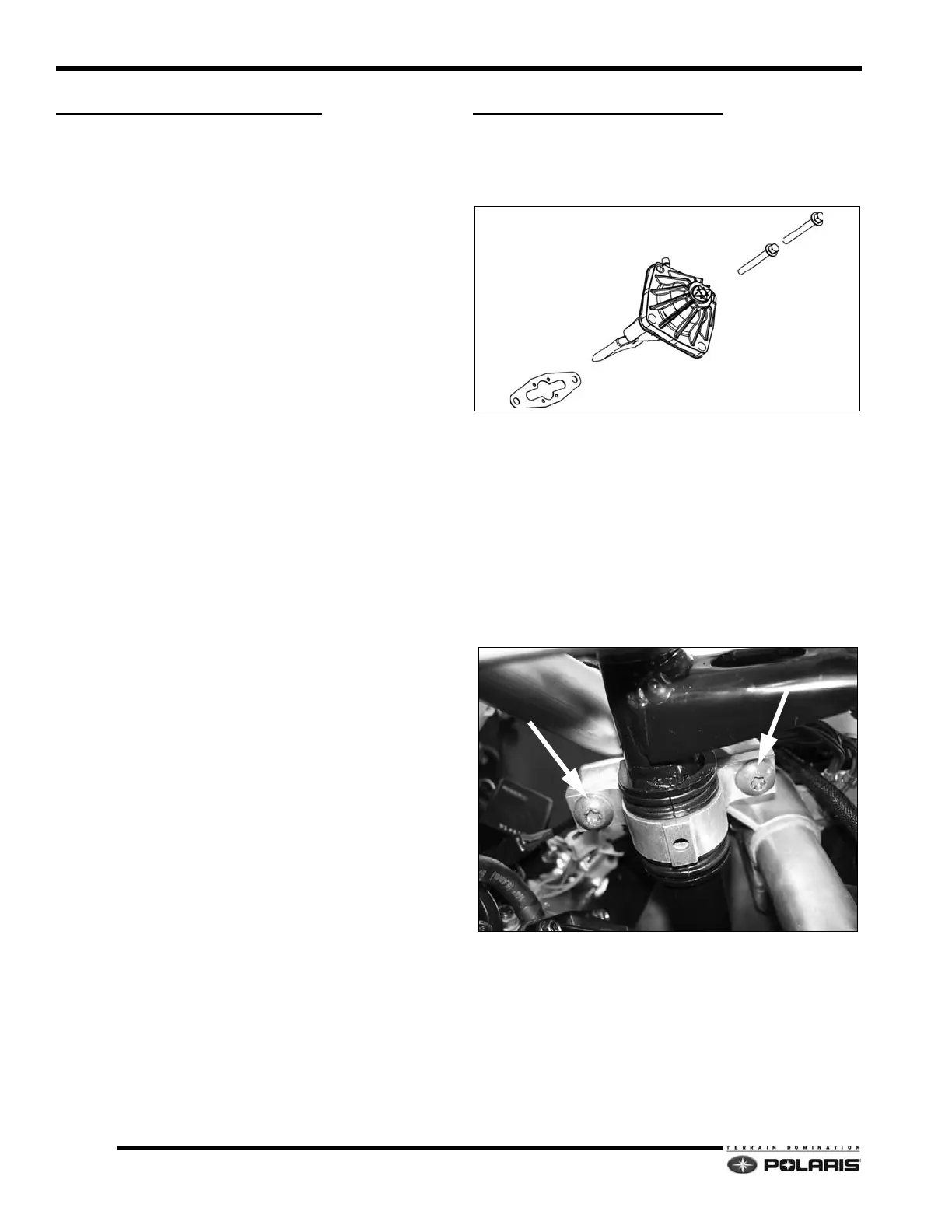

4. Remove the two screws that secure the lower steering

s

haft clamp to the over structure. Doing this will

provide clearance to remove the EV valve assembly.

5. Carefully extract the guillotine out of the cylinder.

Discar

d the gasket. Do not excessively push on the

lower steering shaft when removing the EV assembly.

6. Using a clean rag or shop towel, remove the oil

residue from the c

ylinder, guillotine, and EV base.

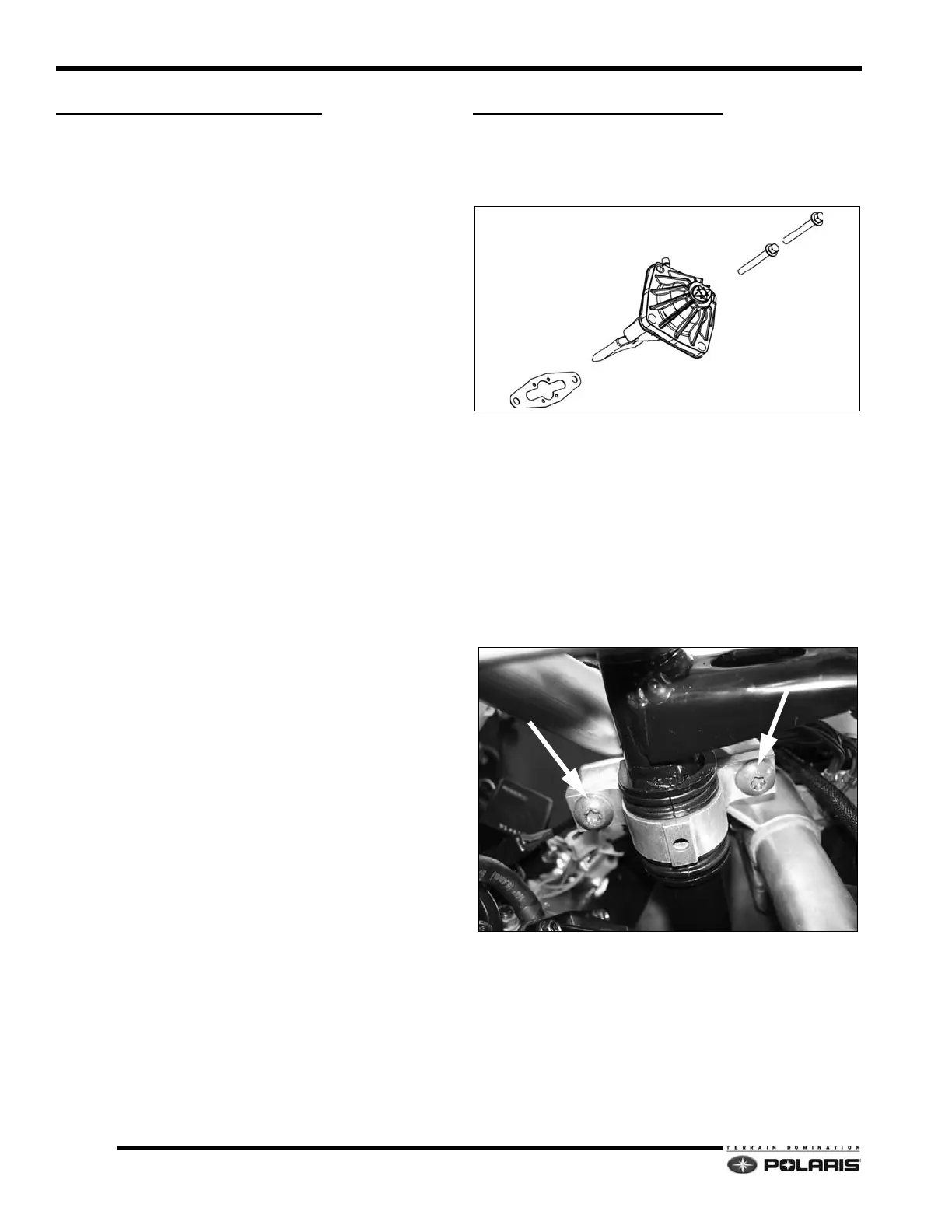

GASKET

EV ASSEMBLY

FASTENERS

GUILLOTINE

Loading...

Loading...