3.29

Engine/Cooling/Exhaust

3

Cylinder Head/Cylinder/Piston Notes

800 pistons feature two different rings thicknesses. The

upper ring is 1.8mm thick, while the lower ring is 1.5mm

thick.

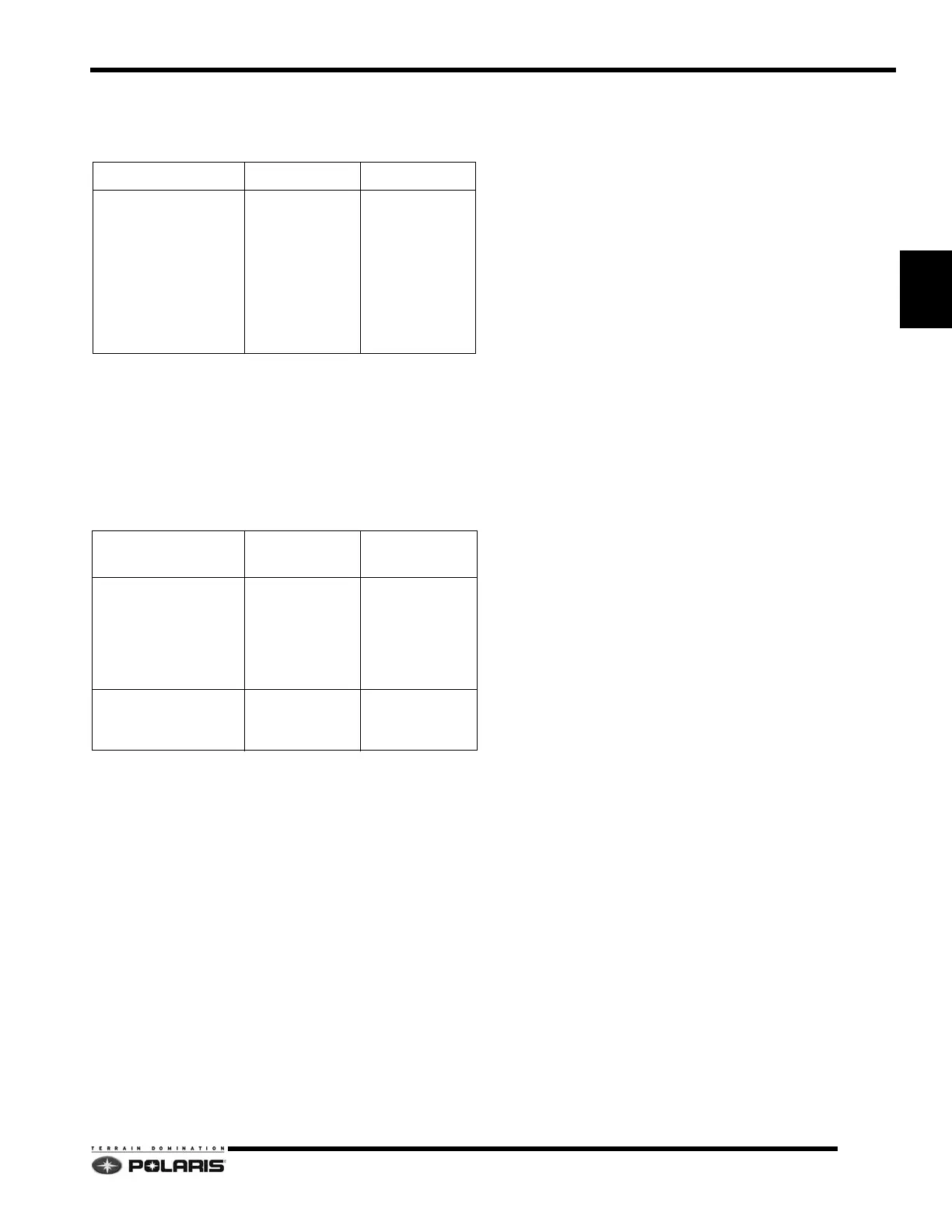

Some 800 DC-CFI-2 engines feature a coolant bypass

n

ozzle on the cylinder head. Reference table below.

800 DC-CFI-2 Cylinder Head/Cylinder/

Pistons Disassembly/Assembly

1. Remove the coolant from the engine using a siphon,

wet/dry vac, or drain pan.

2. Remove the air box, exhaust pipe and resonator from

th

e engine compartment.

3. Remove the high tension wires and spark plugs from

the

cylinder head.

4. Remove the thermostat housing outlet cooling hose

fro

m the housing.

5. Loosen all, then remove all head cover fasteners.

Clea

n the fastener threads to remove any thread

locking residue.

6. Discard the head cover and cylinder head o-rings.

Always us

e new o-rings during assembly.

7. Inspect the cylinder head / combustion domes for any

da

mage. Measure cylinder head flatness. Replace

cylinder head if required.

8. Remove the fuel rail and fuel injectors from cylinder.

See “Fuel Rail/Injector Remova

l and Installation” on

page 4.27.

NOTE: Leave the exhaust Y-pipe attached to the

cylinder assembly. Remove Y-pipe after

removing

cylinder from crankcase.

9. Loosen all, then remove the cylinder bolts. Clean the

b

olt threads to remove any thread locking residue.

10. Carefully pull the cylinder upwards taking care not to

d

rop the pistons and rods abruptly against the

crankcase.

11. Remove the cylinder base gasket. Use a gasket

scra

per to clean the gasket residue from the

crankcase and cylinder base.

12. Inspect the cylinder walls. Nicasil cylinders can only

b

e lightly honed using a 320 grit stone. Damage that

cannot be removed with a light hone requires cylinder

replacement or re-chroming.

13. Inspect the crankcase and cylinder mating surfaces

fo

r warping.

14. The assembly process is the reverse of disassembly.

15. Always use new gaskets and o-rings during

a

ssembly. Liberally coat the inside of each cylinder

bore and the outside of each piston with Polaris two-

stroke engine oil.

16. Always refresh the cylinder crosshatch pattern using

a

320 grit stone. See “Cylinder Honing” on page 3.14.

17. When installing a piston into a

cylinder, verify each

piston ring opening is located at each piston ring

locating pin. Squeeze the top ring, then carefully slide

the cylinder over the compressed ring. Do the same

with the bottom ring.

18. Follow the torque specifications and torque

se

quences located at beginning of chapter when

tightening fasteners.

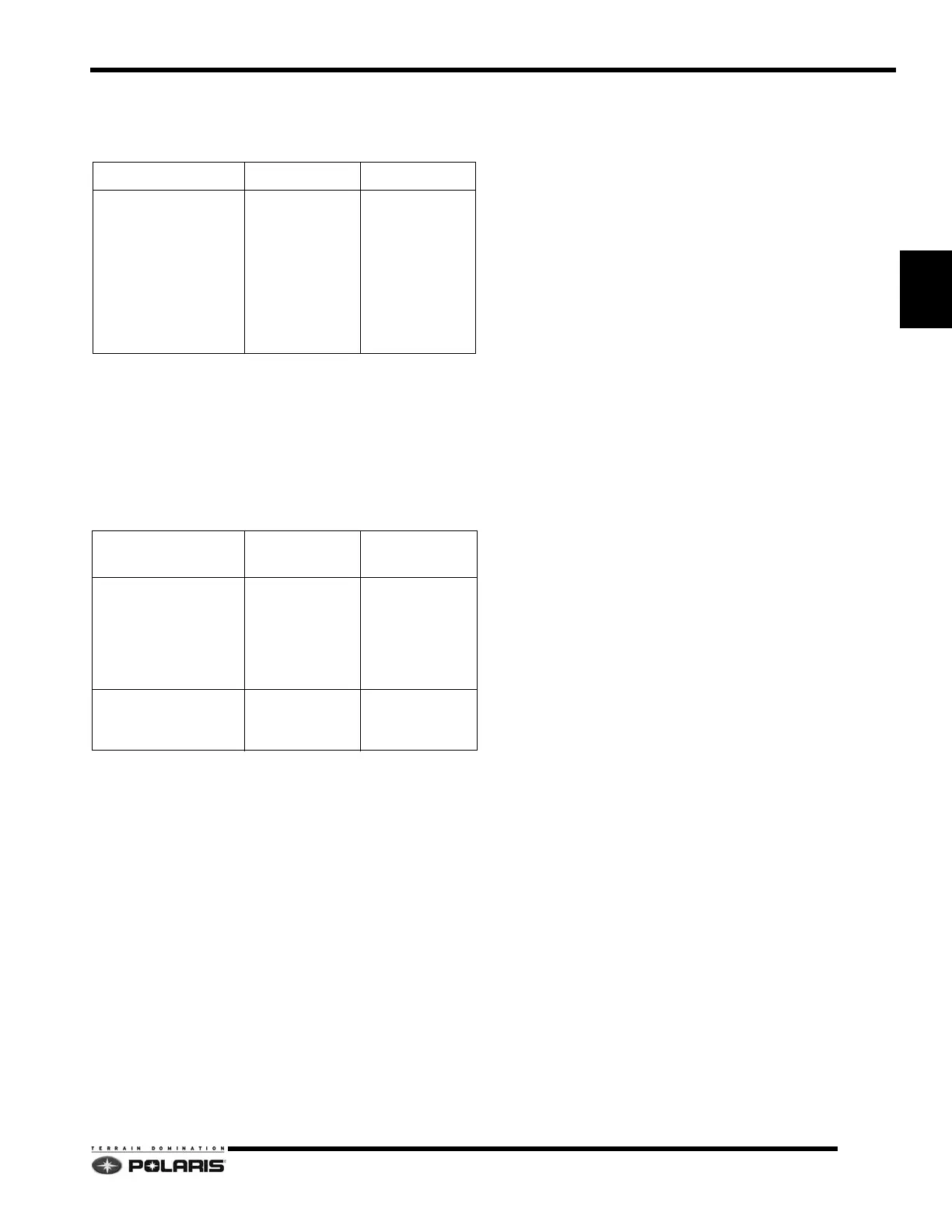

Piston Matrix

Engine Model Piston PN Piston ID

S4139-8044-OO8G

S4229-8044-OO8G

S4092-8044-OO8G

S4360-8044-OL8G

S4361-8044-OL8G

S4359-8044-OL8G

S4509-8044-0A8G

S4510-8044-0A8G

S4508-8044-0A8G

2204322 3305 or 3335

Plug / Bypass Matrix

Engine Model

Cylinder Head

Plug

Cylinder Head

Byp

ass Nozzle

S4139-8044-OO8G

S4229-8044-OO8G

S4360-8044-OL8G

S4361-8044-OL8G

S4509-8044-0A8G

S4510-8044-0A8G

X

S4092-8044-OO8G

S4359-8044-OL8G

S4508-8044-0A8G

X

Loading...

Loading...