6.25

PVT System

6

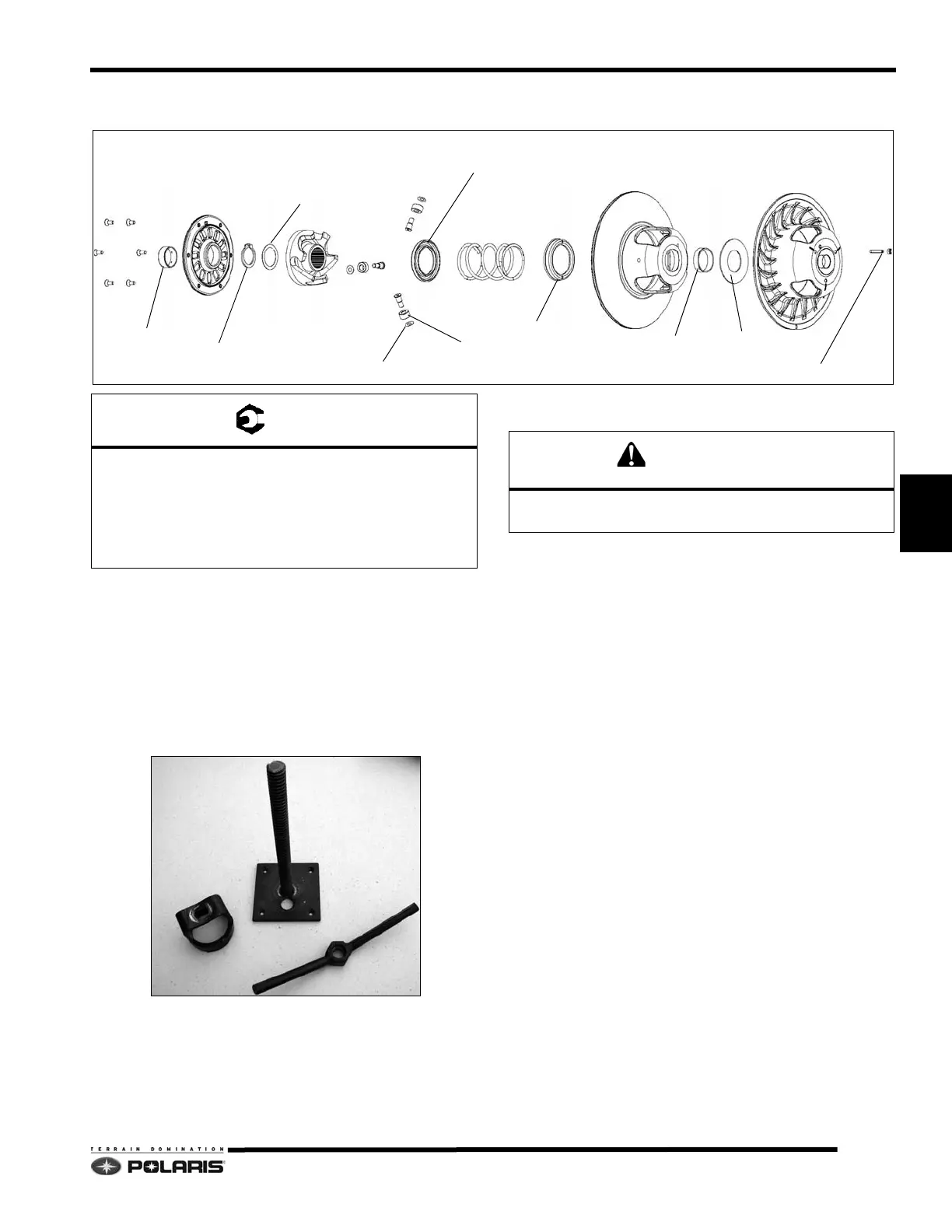

Polaris SPA-P2 Driven Clutch Components

Disassembly and Assembly Process

1. Remove the driven cover screws and cover. Note the

“

X” in the cover and moveable sheave are in

alignment.

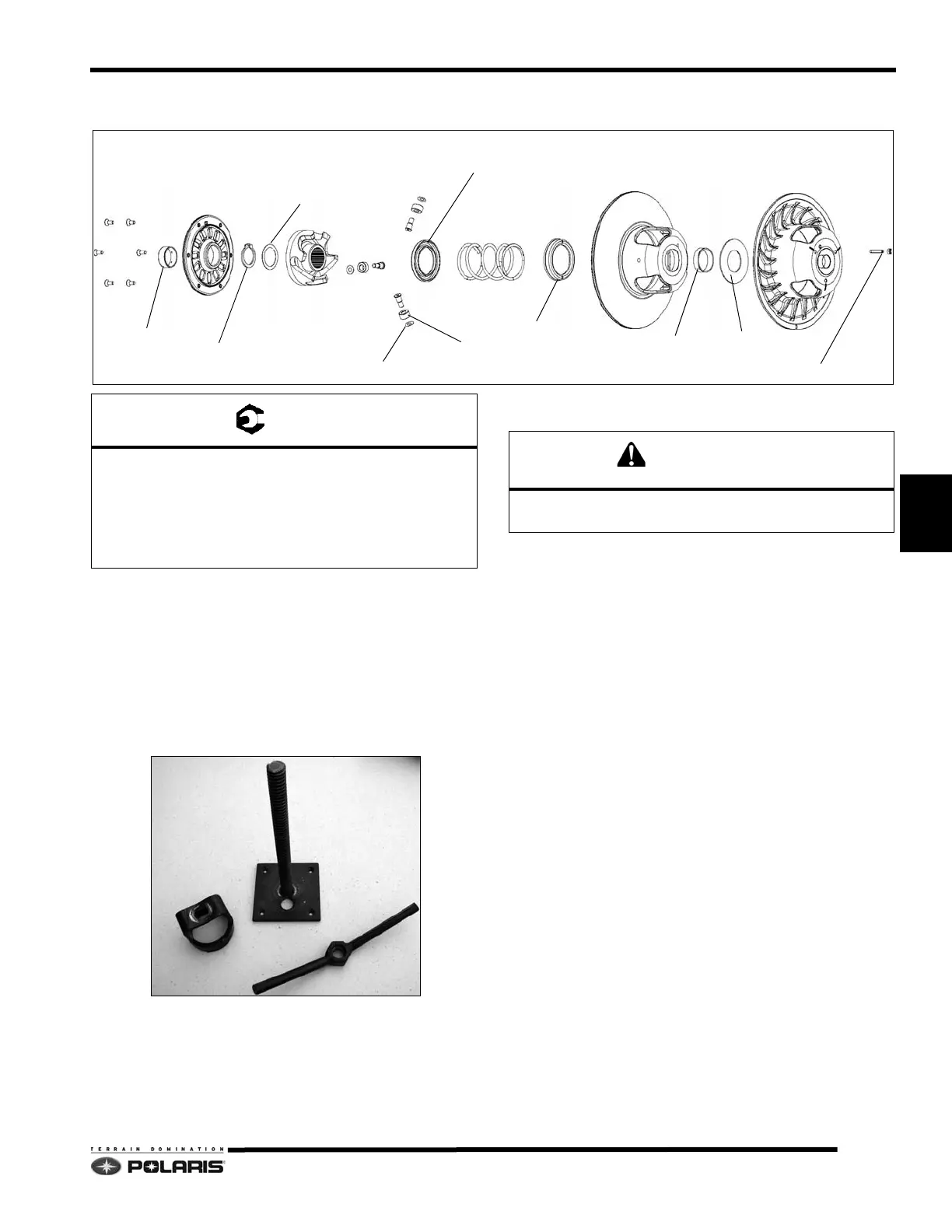

2. Install the clutch into a s

crew-down clutch

compression fixture. Screw-down clutch compressors

are commercially available through after-market

companies such as Team Industries Inc.

NOTE: The 8700220 clutch compressor and PS-45909

e

xtensions will not work on a P2 driven clutch.

3. Remove the snap ring. Verify the washer is not lodged

in

side the snap ring groove.

4. Unscrew the compressor to remov

e the helix, spring

cups and spring. Note the orientation of the spring

spacer, spring cup, and tabbed spring. Disassemble

the clutch sheaves.

5. Inspect the helix, cup/spacer, spring, bushings,

r

ollers, and clutch sheaves for damage.

6. The cover and sheave bushings are not serviceable.

If bush

ings are severely worn or binding, clutch

assembly replacement is required.

7. Clean the sheaves with a Scotch Brite pad and a

solution of

warm, soapy water.

8. Inspect the rollers for abnormal wear and replace as

re

quired. Install new rollers with the ejector pin marks

on the rollers facing center of sheave (visible).

9. Install the sheave spacer, and then the moveable

sh

eave.

10. Next, install the metal spring cup, spring, and then

sp

ring spacer. Make sure the spring tab is in one of

the spring cup holes, and engaged in the moveable

sheave hole.

11. Slide the helix down the stationary shaft.

DRIVEN COVER

RETAINING RING

WASHER

HELIX

SPRING w/TAB

WASHER

ROLLER

MOVEABLE SHEAVE

BUSHING

BUSHING

SPACER

STATIONARY SHEAVE

ADJUSTER SCREW / LOCK NUT

SPRING CUP w/TAB HOLES

(NO SERVICE)

(NO SERVICE)

SPACER

Driven Cover Screws: 12 ft-lbs (16Nm)

Deflection Adjuster Screw Lock Nut: 10 ft-lbs

(12Nm)

Driven Clutch Retaining Fastener: 18 ft-lbs (25 Nm)

Roller Fasteners: 110 in-lbs (12.5 Nm)

Driven spring under pressure. Wear eye protection

when removing snap ring and helix.

Loading...

Loading...