6.15

PVT System

6

PVT SYSTEM ADJUSTMENTS

Clutch Alignment/Offset

The drive and driven clutches are offset from each other.

This offset is controlled by the number and thickness of

washers installed on the jackshaft behind the driven

clutch.

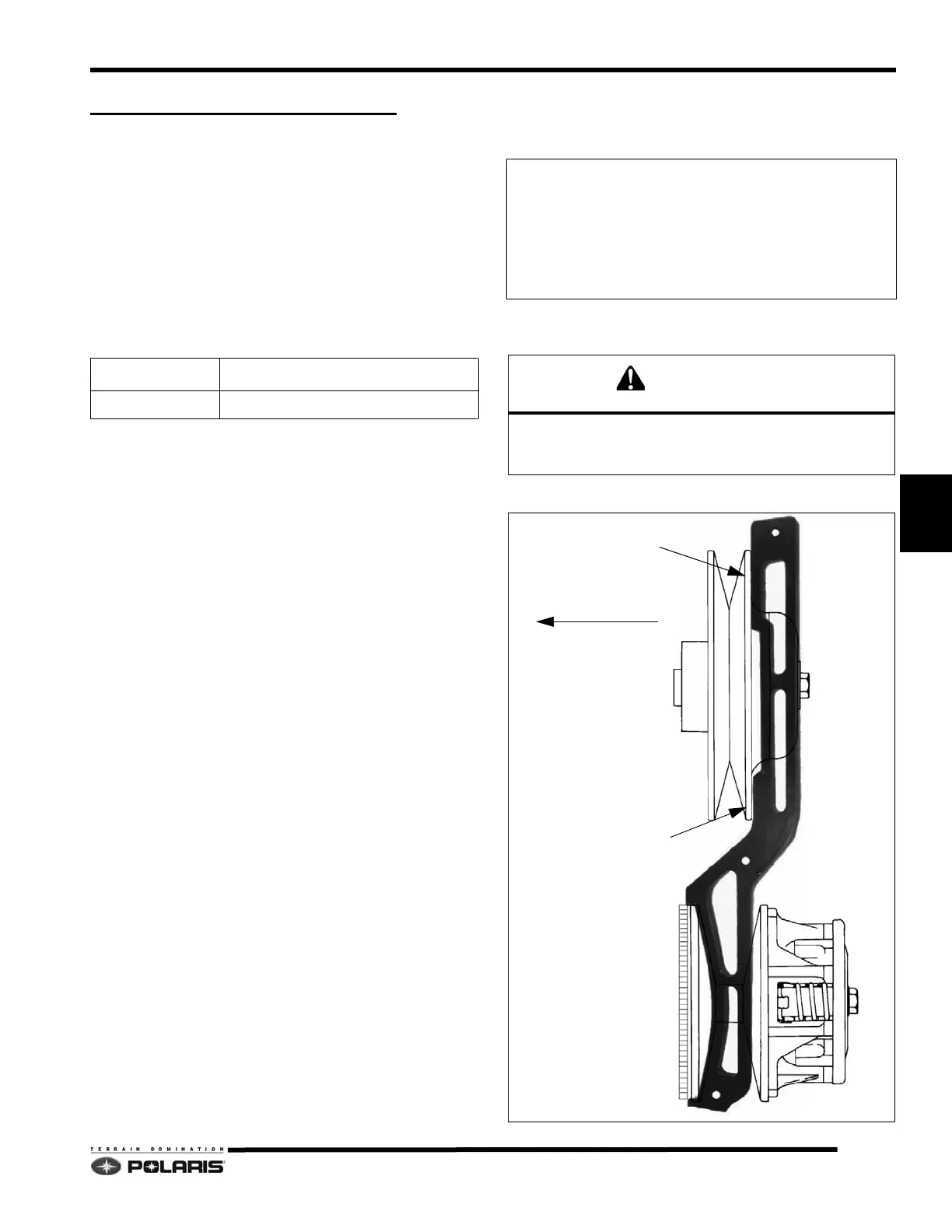

1. Remove drive belt.

2. Push the driven clutch towards the bulkhead. Install

the

alignment tool into the drive clutch and on top of

the driven clutch hub.

NOTE: The PS-47477 offset tool is calibrated with the

c

orrect alignment angle for the respective driven

clutch.

Inspect for broken motor mounts, engine straps or

bu

lkhead damage if the offset tool reveals major mis-

alignment.

3. The optimum setup is when the front and rear of the

too

l touch the driven clutch. No gap should be present

in the front, and the rear clearance should not exceed

.060" (1.5mm).

NOTE: If the front of the alignment bar does not touch

t

he driven sheave, the maximum clearance cannot

exceed .025

(.64mm).

Offset/Float Adjustment

1. Determine direction driven clutch needs to be

adjusted.

2. Remove driven clutch retaining bolt, and remove

dr

iven clutch.

3. With one 16 GA. bushing installed, add or remove

offset washer

s from behind the driven clutch to set the

proper offset.

4. After adjusting the offset, add or remove shim

washe

rs from behind the driven clutch bolt and

washer to provide a .060" (.1.5mm) driven clutch float

on the jackshaft.

AR = As Required

TOOL PART NUMBER APPLICATION

PS-47477 Light Weight (LWT) Team Driven / P2

Driven Clutch Offset/Shim Washers

Offset Washers

16 Gauge Bushing=7556509 (QTY.1)

.023” = 7555917 (AR)

.120” = 7555864 (AR)

Float Washers

.065" = 7555806 (AR)

.105" = 7555832 (AR)

Always verify the driven clutch floats on the jackshaft.

The jackshaft bearing will fail from side-loading if the

driven clutch is not allowed to float.

0” - .060”

TOUCHING

(PN: PS-46998 Shown)

PUSH CLUTCH

Loading...

Loading...