7.29

Shocks

7

FOX™ PS-5 DISASSEMBLY

TIP: Extreme cleanliness is very important during all

disassembly and reassembly operations. This prevents

dirt or foreign particles from entering the shock, which

causes premature failure.

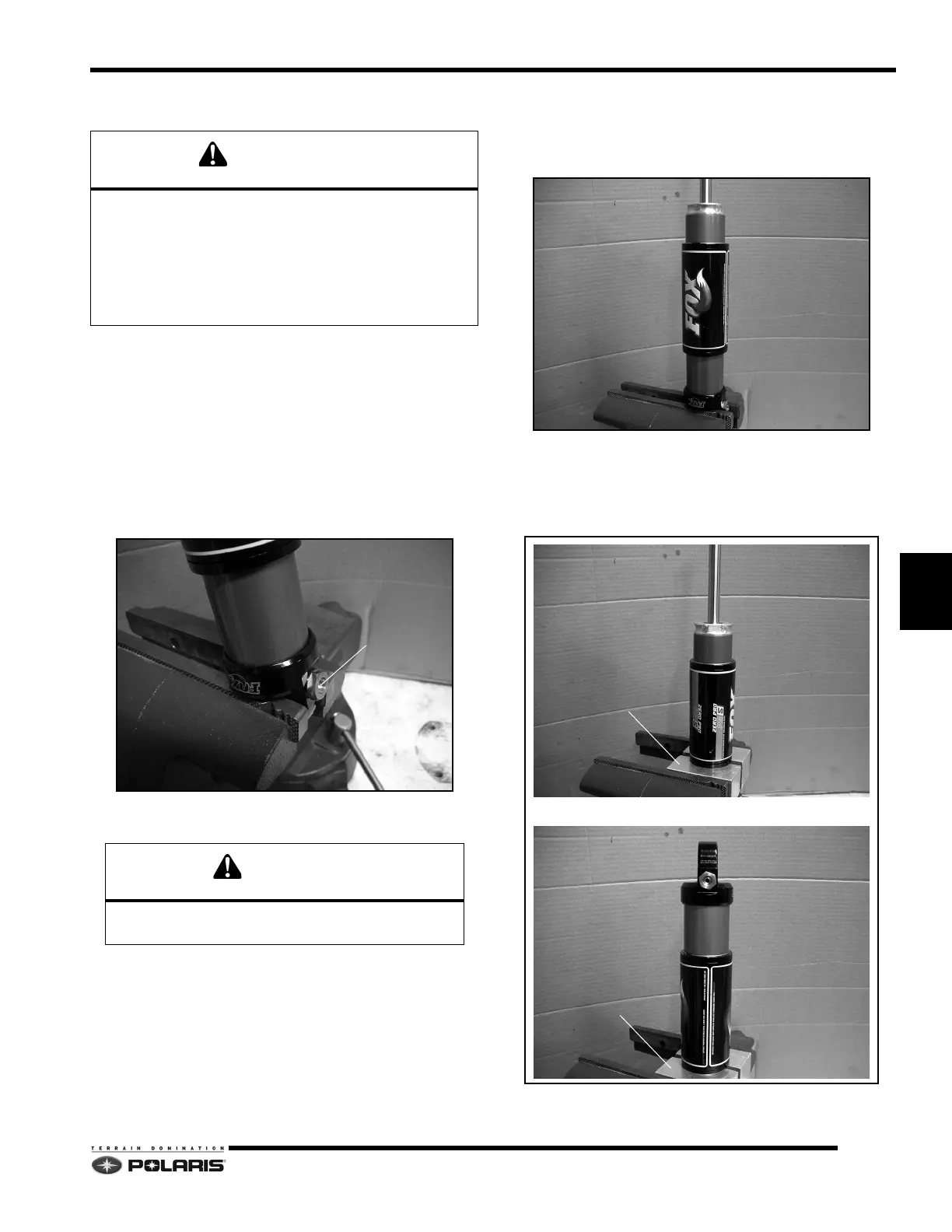

1. Remove the shock from the vehicle. Clean the shock

assem

bly thoroughly with warm, soapy water.

2. Remove eyelet bushings and sleeves from body cap

an

d shock rod eyelet.

3. Remove the button head screw from the charge port.

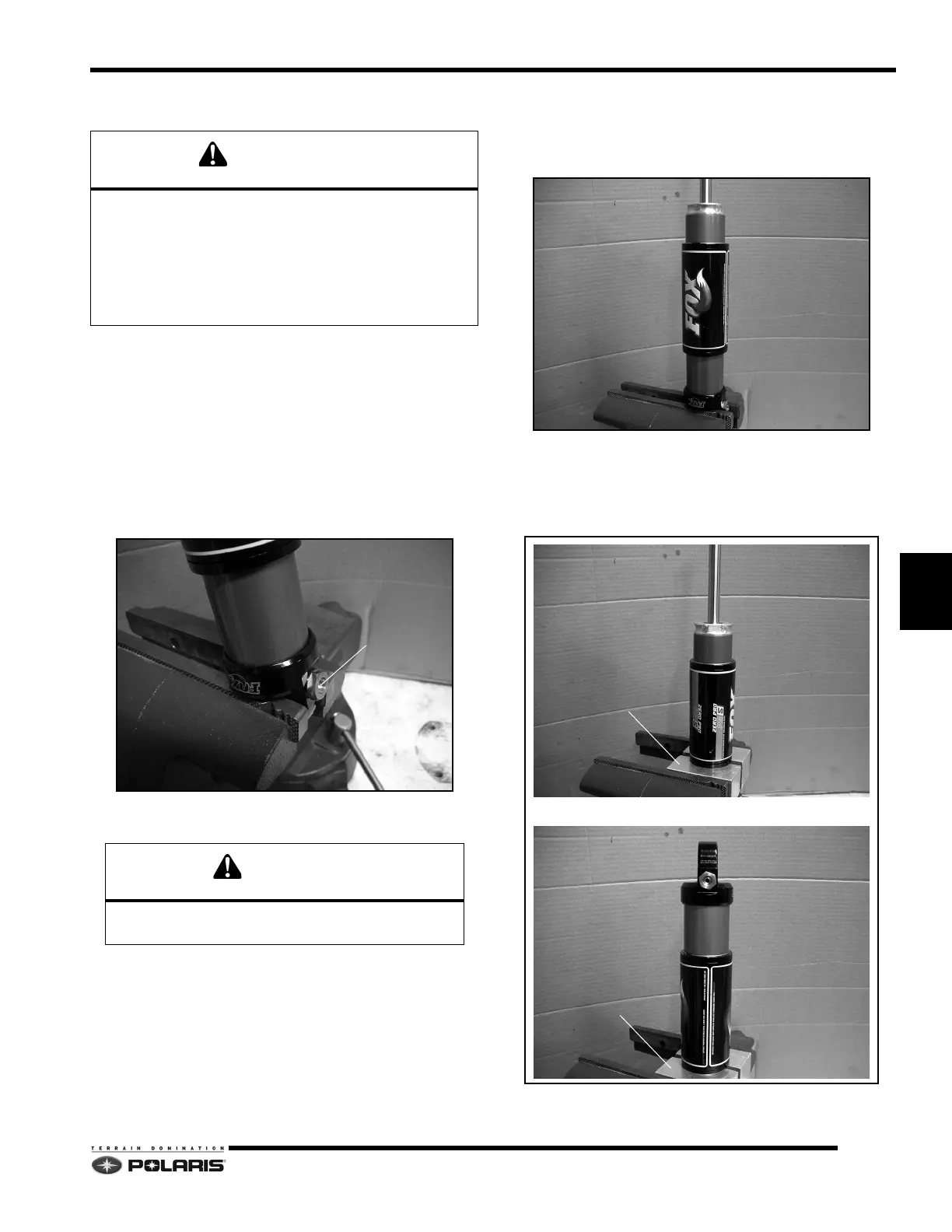

4. Secure the shock body cap in bench vise with the

charge port

accessible.

5. Insert the needle of the gas fill tool into the c

harge port.

Depress the fill tool and discharge the nitrogen gas.

Push the shock rod down to expel all of the gas.

6. When the shock is completely discharged, remove the

gas

fill tool needle in a straight, smooth motion.

7. Using the 1 3/8” wrench, loosen and unscrew the

b

earing assembly from the shock body. If the body

cap unscrews instead of the bearing, that is OK. You

will need to remove both for this rebuild procedure.

8. Clamp the shock in the vice using the body clamp

blocks

(2871071). If the bearing is still in the body, use

wrench to remove the bearing. If the body cap is what

needs removal, use a large crescent wrench to loosen

and unthread the body cap.

Shocks contain high pressure nitrogen gas. Extreme

caution must be used while handling and working with

shocks and related high pressure service equipment.

The pressure must be released from the shock before

disassembly. It is strongly recommended you wear

safety glasses and ear protection during these

procedures.

Point air valve away from face and body when

charging or discharging any shock.

Loading...

Loading...