10.26

Battery and Electrical Systems

IGNITION TIMING

Timing Procedure

NOTE: Before performing procedure, verify there are

no current trouble codes and that all of the engine

electrical connections are clean and tight.

1. Reference the timing specification chart and locate

th

e piston BTDC measurement for 18°.

2. Install a dial indicator gauge into the MAG spark plug

ho

le.

3. Place the MAG piston at 18° BTDC.

Mark the flywheel.

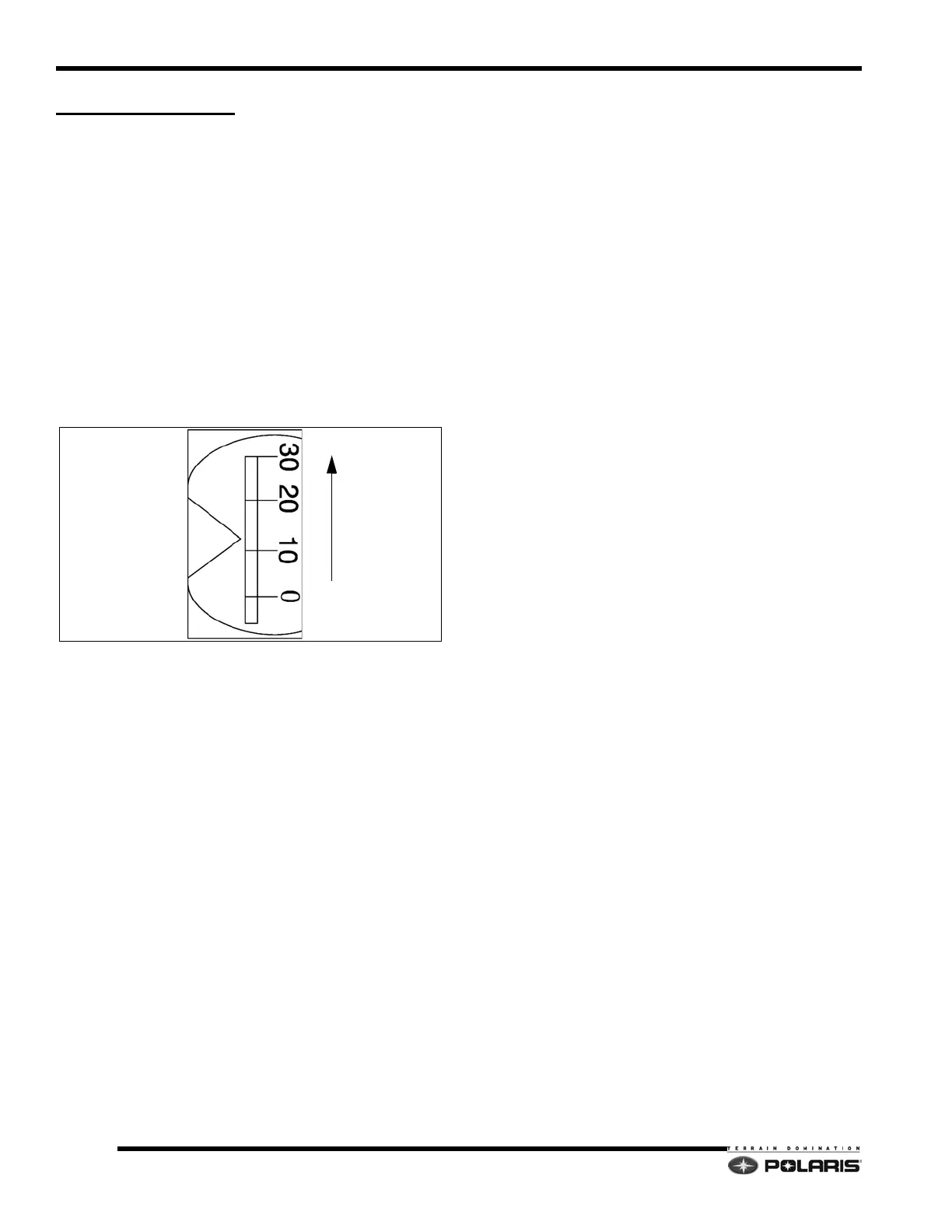

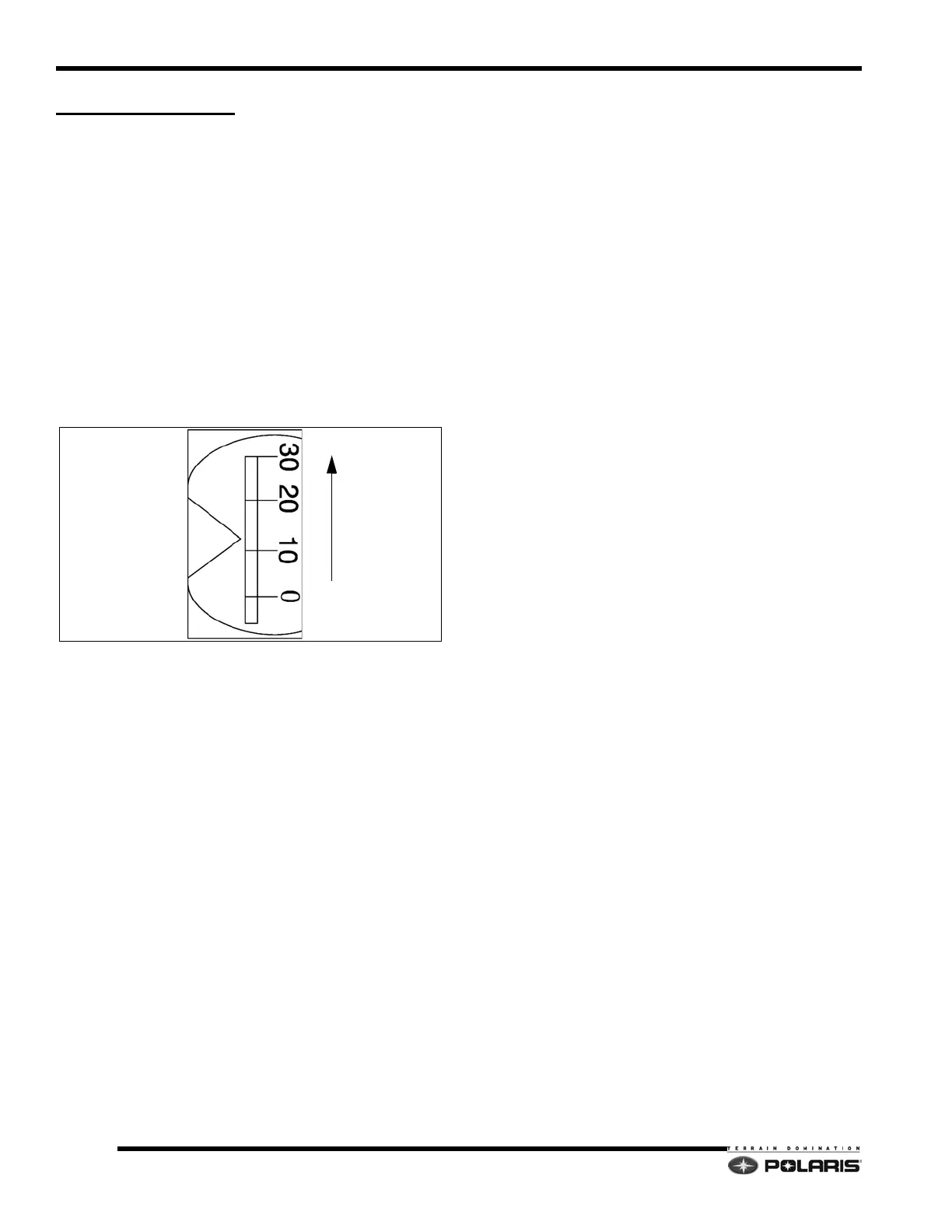

NOTE: Each 10 degree mark is separated by lines

e

very 2 degree. Acceptable timing variance is +/- 2

degrees.

4. Connect timing light to the engine according to

ma

nufacturer's instructions.

5. Start and run the engine at idle speed until the engine

tem

perature is 120°F (49°C). Verify the throttle lever

is closed and the engine is at idle speed (1700 +/- 100

RPM).

NOTE: The engine temperature must be

a

pproximately 120°F (49°C) to obtain accurate timing

specification.

6. Point the timing light at the timing inspection hole.

7. With your head positioned so there is a straight line

b

etween your eye, the stationary pointer and the

crankshaft center line, note the relative position

between the marked flywheel line and the pointer. If

the stationary pointer is aligned with the mark made

in Step 3, or within the acceptable variance, ignition

timing is correct.

NOTE: The stator plate, two-tooth, and five-tooth

c

rankshaft position sensor locations are not

adjustable.

8. If the pointer is outside the variance, either the

f

lywheel key has sheared allowing the flywheel to

move on the crankshaft, the crankshaft is out of index,

a problem with the engine electrical harness exists, or

one of the crankshaft position sensors has moved.

Loading...

Loading...