2.12

Maintenance

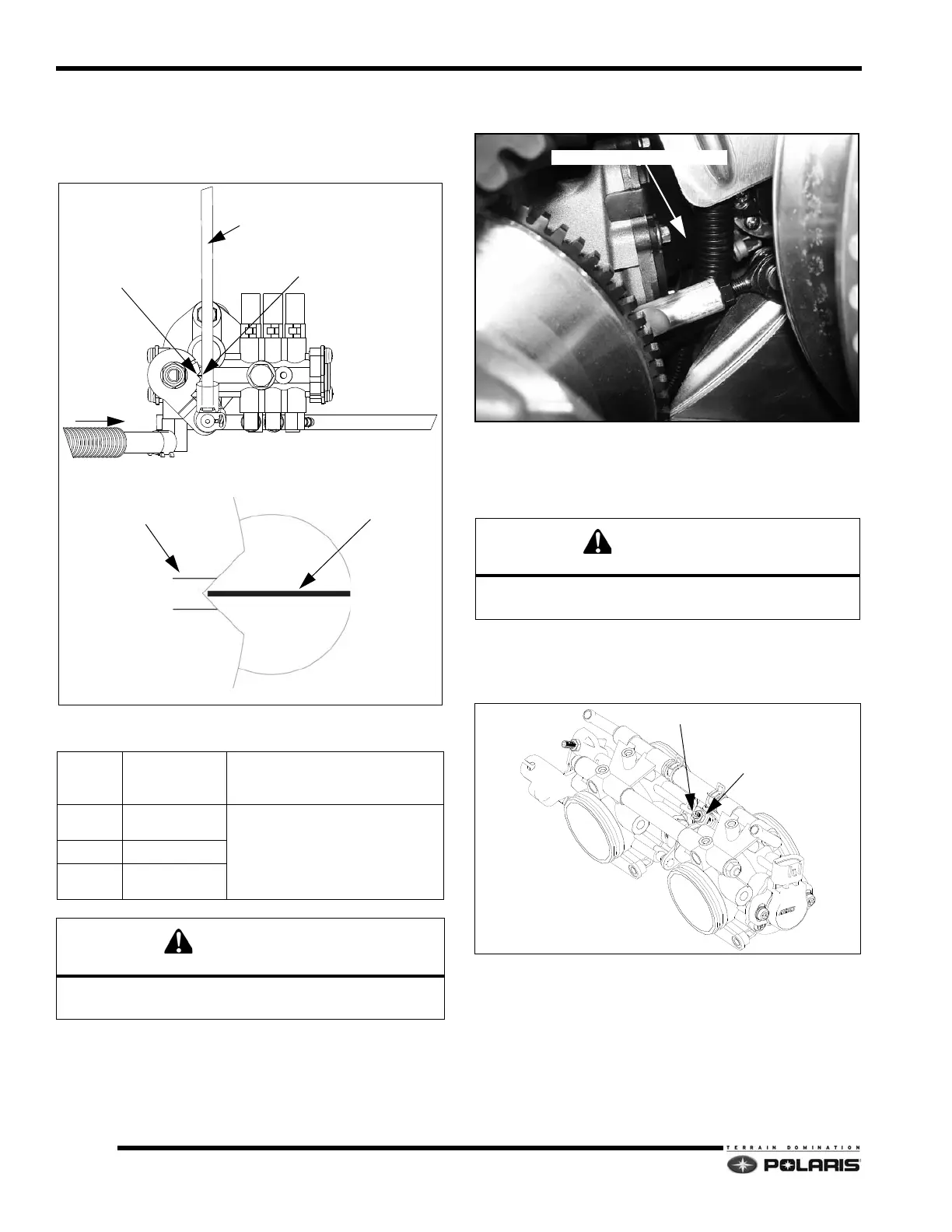

Oil Pump Adjustment

1. Verify the throttle cable free play is set to specification

(.010 - .030) and the throttle lever is synchronized to

the throttle plates.

2. Remove the following components:

• Left side compartment door panel

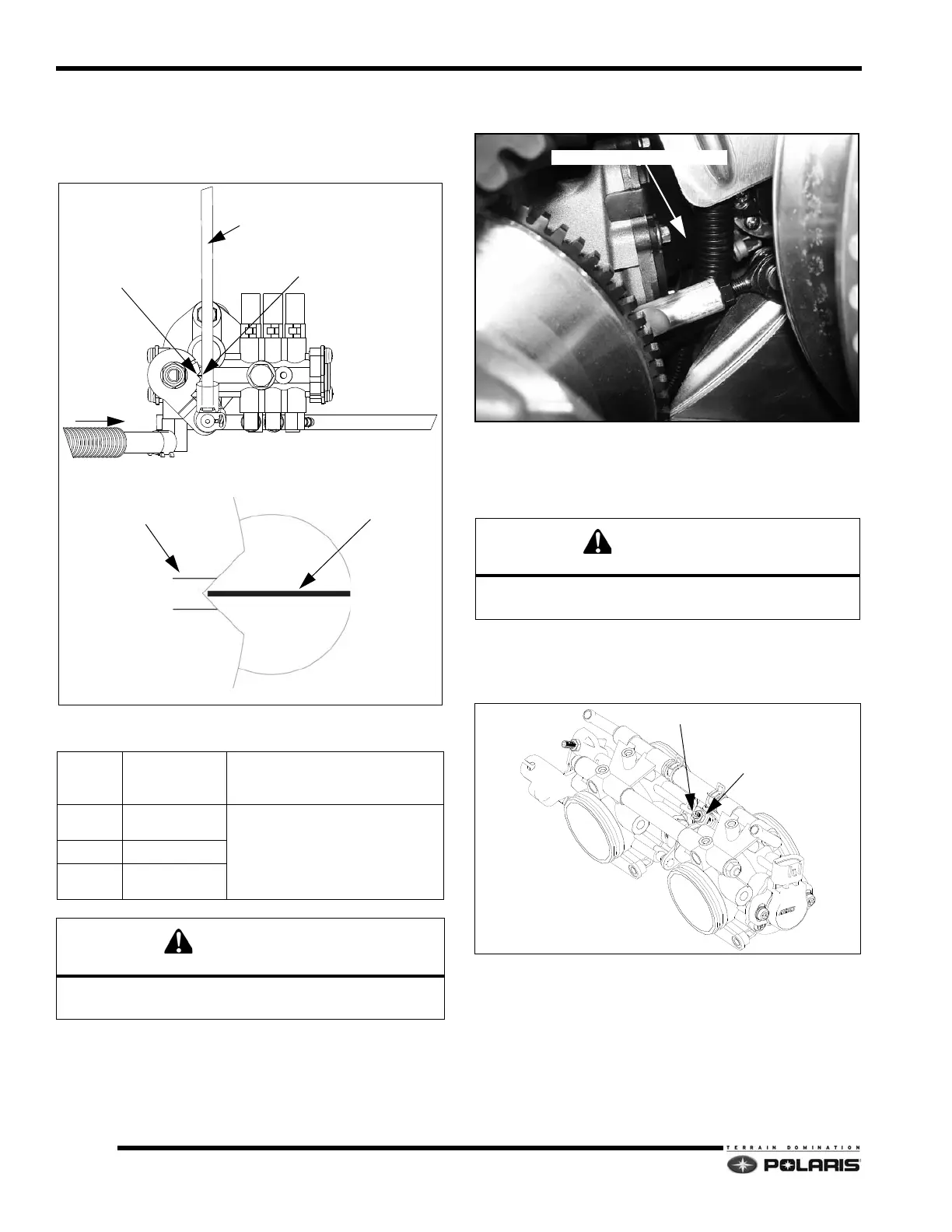

3. Access to the oil pump for inspection is between the

drive

and driven clutches.

4. Using a mirror and a flash light, visually inspect the

cu

rrent oil pump setting. The scribe mark should be

aligned with the point of the lever notch when the

throttle plates are closed.

5. If adjustment is required, locate

the oil pump linkage

adjuster on the throttle body. Open and release the

throttle several times to verify throttle plates are

closed.

6. Loosen the adjuster jam nut. Using an Allen wrench,

tu

rn the adjuster screw clockwise to raise the oil pump

lever arm. Turn the screw counter-clockwise to lower

the oil pump lever arm.

7. Visually inspect the lever notch/scribe mark

align

ment. When in alignment, tighten the jam nut

without moving the adjuster screw.

Oil Pump Adjustment Settings

PART

NUMBER

ARM

MARKING LEVER SETTING

2521000

1204439

600B

Set lever notch in-line with oil pump scribe

mar

k.

1204695 600C

1204363

1

204438

800B

Failure to properly set the oil pump lever arm may cause

severe engine damage.

LINKAGE ARM

OIL SUPPLY

LEVER NOTCH

SCRIBE MARK

SCRIBE MARK

SCRIBE MARK ALIGNED TO

CENTER OF NOTCH +/-

WIDTH OF SCRIBE MARK

The oil pump lever and pump boss marks must be

observed straight-on to yield accurate results.

LOOK THROUGH THIS OPENING

Loading...

Loading...