3-1

764333-675

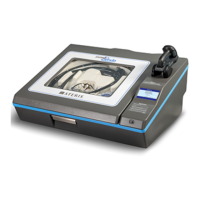

3.1 SYSTEM 1E™ LIQUID CHEMICAL

STERILANT PROCESSING SYSTEM

DESCRIPTION

The SYSTEM 1E Liquid Chemical Sterilant Processing

System is made up of the System 1E Processor, the

Water Preparation unit and the UV Water Treatment

unit. The three units function together as a system and

cannot be altered. The Water Preparation unit includes

the A and B pre-filters, housings and water pressure

regulator. The water pressure regulator is factory set

to 50 psig. The UV Water Treatment unit includes a

stainless steel chamber with quartz sleeve, an ultra-

violent lamp and a UV intensity monitor.

The SYSTEM 1E Liquid Chemical Sterilant Processing

System runs only two cycles: a Liquid Chemical

Sterilization Cycle and a Diagnostic Cycle. There are

no use r or service adju st ments that can be made to alter

either cycle sequence or parameter set points. The

Liquid Chemical Sterilization Cycle is used for the

processing of medical equipment, while the Diagnostic

Cycle is a daily test cycle that verifies the operation of

the unit components.

Accessories such as processing trays and Quick

Connects are not addressed in this manual.

3.2 OVERVIEW OF THE SYSTEM

The SYSTEM 1E Liquid Chemical Sterilant Processing

System is intended for the liquid chemical sterilization

of manually cleaned immersible, reusable, critical and

semi-critical heat-sensitive medical devices, including

endoscopes and their accessories. Devices processed

in the SYSTEM 1E Liquid Chemical Sterilant

Processing System have been chemically sterilized

using S40™ Sterilant Concentrate, a peracetic acid

liquid chemical sterilant, and rinsed with extensively

treated, potable water.

The SYSTEM 1E Processor treats potable water using

a three stage process: pre-filtration, UV irradiation,

and 0.1 micron filtration.

• The pre-filtration stage reduces particulates present

in the potable water.

• The UV irradiation stage reduces waterborne

pathogenic viruses in the unlikely event that they

are present in potable water.

• The dual membrane, 0.1 micron pharmaceutical

sterilizing-grade filter effectively removes bacteria,

fungi and protozoa from the rinse water.

After completion of the cycle for the SYSTEM 1E

Processor (which includes liquid chemical sterilization

and rinse phases), the load is ready for immediate use.

Once removed from the SYSTEM 1E Processor the

devices are wet. Critical devices

1

and some semi-

critical devices are processed within containers. The

containers are closed with transparent lids; the

containers are not designed for sterile storage and

medical devices should not be stored after processing

in SYSTEM 1E Processor. Processed medical devices

should be used immediately to minimize the risk of

environmental contamination.

SYSTEM 1E Processors are to be used only by trained

personnel who are fully familiar with, and strictly

comply with, the operating instructions and

conditions detailed in the Operator Manual, as well as

any applicable Quick Connect Processing Instructions.

The warranty pertaining to equipment or products

sold by STERIS is contained in STERIS’s Terms and

Conditions of Sale.

Important: Liquid chemical sterilization of a surgical

or diagnostic device by the SYSTEM 1E Processor

requires that the liquid sterilant make contact with all

exterior and interior surfaces of the device. In the case

of a device having internal channels or other interior

surfaces, the device manufacturer’s instructions

should be reviewed to determine the manufacturer’s

recommendations for the preparation of the device for

liquid chemical sterilization or disinfection. STERIS is

not responsible for the adequacy of the device

manufacturer’s instructions or the design of the device

which fails to permit liquid to contact the surfaces of

all internal channels and components of the devices.

The device will not be liquid chemically sterilized if

the sterilant does not contact all interior and exterior

surfaces of the device.

3.3 COMPONENT DESCRIPTION

Refer to Figure 3-1 for this section. This figure shows

the general components used in the SYSTEM 1E Liquid

Chemical Sterilant Processing System. The unit can be

broken down into the following subsections:

1. Fluid Pathway

2. Housing of Water Filter

3. Air Manifold

3.3.1 Fluid Pathway Description of SYSTEM 1E

Processor

1. Due to their size, a limited number of critical devices are processed in a processing tray. Go to www.steris.com

to determine how a specific device is processed.

Section 3: Principles of Operation

Loading...

Loading...