4-1

764333-675

4.1 General

Maintenance procedures described in this section

should be performed at regular intervals, as indicated.

The frequency indicated is the minimum, and should

be increased if usage of the unit demands. Should a

problem occur, refer to S

ECTION 5, TROUBLESHOOTING.

4.2 Daily Maintenance of SYSTEM 1E

™

Liquid Chemical Sterilant Processing

System

WARNING – PERSONAL INJURY AND/OR

EQUIPMENT DAMAGE HAZARD:

Disconnect all utilities to SYSTEM 1E

Liquid Chemical Sterilant Processing System

before servicing. Do not service the SYSTEM 1E

Liquid Chemical Sterilant Processing System

unless all utilities have been properly locked out.

Always follow OSHA Lockout-Tagout and

electrical safety-related work practice standards.

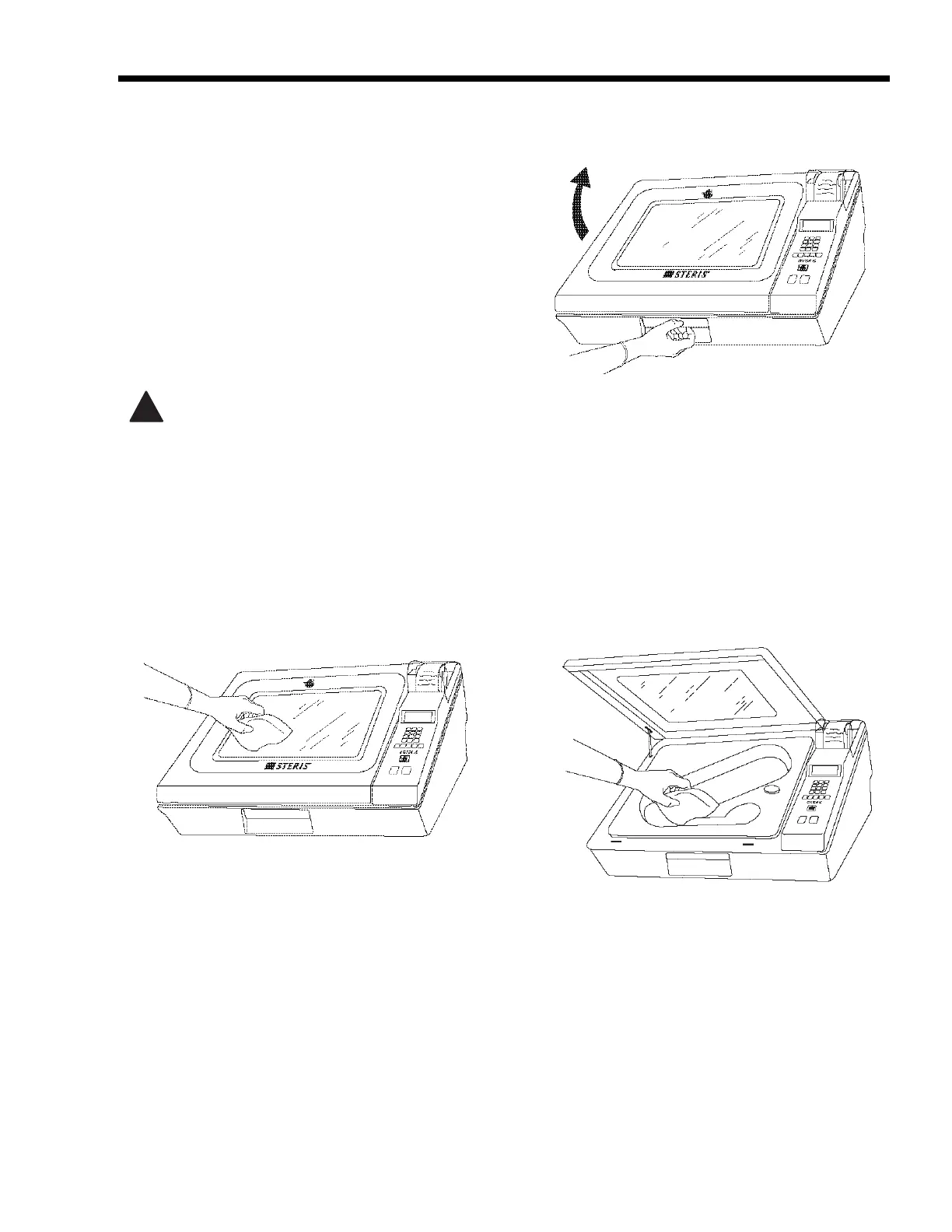

1. Clean external surfaces (Figure 4-1).

Wipe SYSTEM 1E Processor with a soft cloth

dampened with 70% isopropyl alcohol.

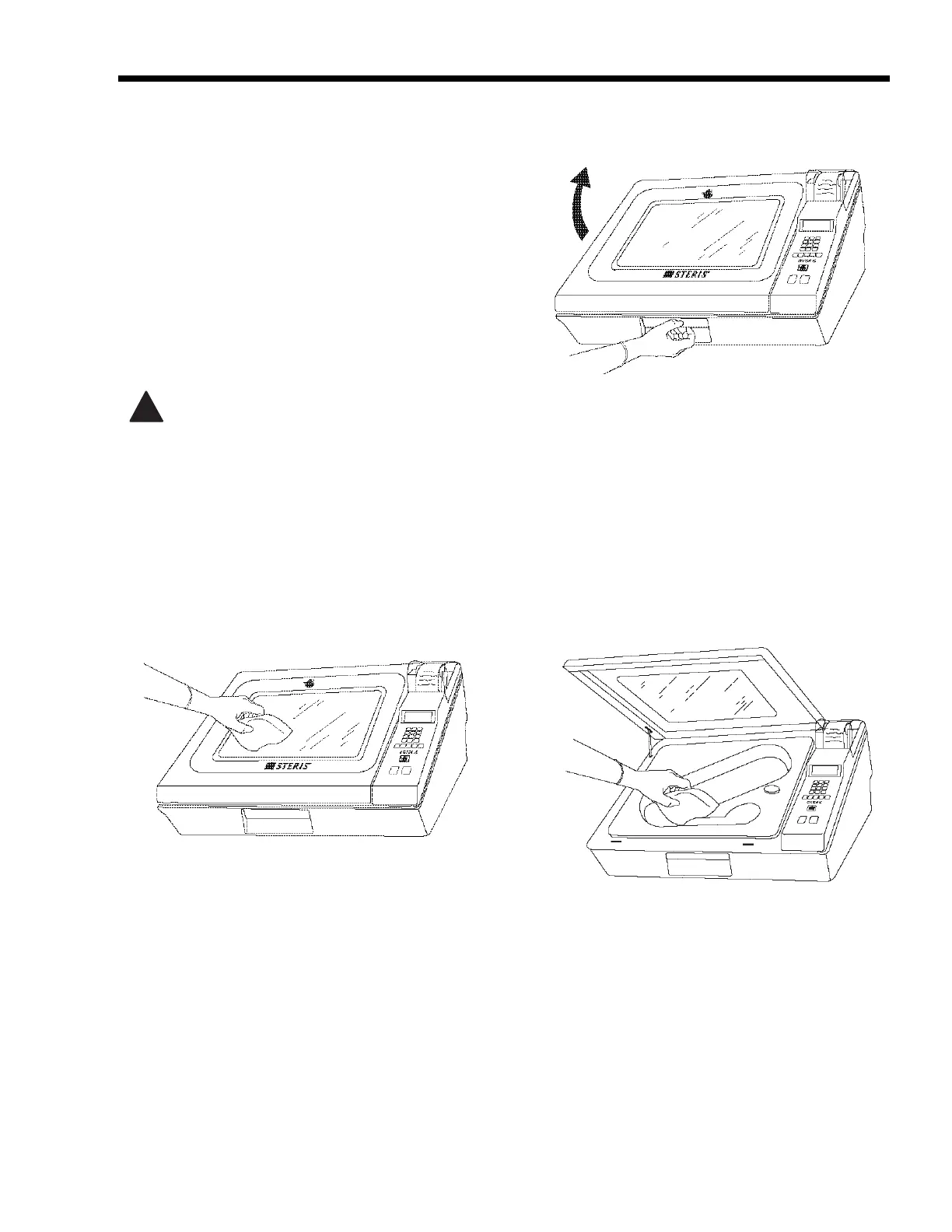

2. Open lid (Figure 4-2).

3. Clean Tray for Processing (Figure 4-3).

Tray/container for Processing: Wipe inner

surface and seal, tray/container for processing, and

accessory rack with a soft cloth dampened with 70%

isopropyl alcohol.

Figure 4-1. Clean SYSTEM 1E Processor

External Surfaces

Figure 4-2. Open Lid

Figure 4-3. Clean Tray for Processing

Section 4: Inspection and Maintenance

Loading...

Loading...