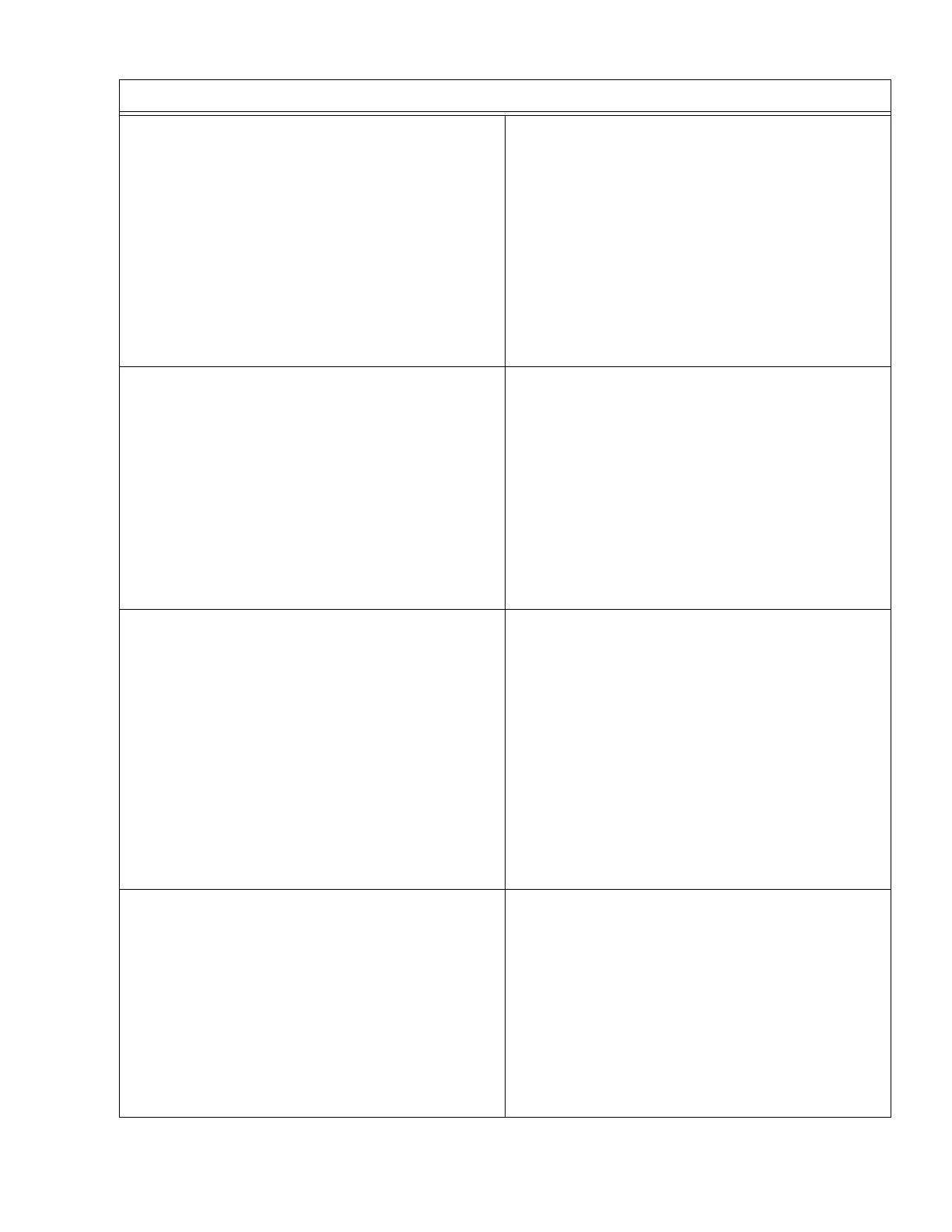

5-5

764333-675

5.1.7 Concentration Low

Description – Control measures less than 175 counts

during exposure.

Action:

1. No S40™ Sterilant Concentrate – run cycle again

with S40 Sterilant Concentrate.

2. Sterilant builders/buffers hardened – run cycle

again with fresh S40 Sterilant Concentrate.

3. Scale build-up on CP1 and CP2 – clean.

4. Faulty CP1 and CP2 connection – repair.

5. Out of calibration – recalibrate.

6. Faulty control board – replace.

7. Faulty interface board – replace.

5.1.8 Chamber Level Low

Description – SYSTEM 1E Processor senses a not-full

condition during exposure.

Action:

1. Leaking V5 – replace pinch valve sleeve.

2. Faulty SOL4 – repair. (Refer to Figure 5-5.)

3. Faulty LS3 – replace. (Refer to Figure 5-3.)

4. Leaking tray – replace.

5. CK2 or CK3 leaking – replace.

6. Faulty CK8 – rebuild or replace.

7. Leaking lid – replace.

8. Plumbing leak – repair.

5.1.9 Heater Problem

Description – Control senses temperature difference

of more than 7°C between TC1 and TC2.

Action:

1. Clean tray drain strainer.

2. Faulty P1 – replace. (Refer to Figure 5-5.)

3. Faulty SSR4 – replace. (Refer to Figure 5-5.)

4. Faulty TC1 or TC2 – repair or replace. (Refer to

Figure 5-2.)

5. TC1 or TC2 out of calibration – recalibrate.

6. Faulty interface board – replace.

7. Faulty control board – replace.

8. Processor may have been too cold if first cycle of the

day – run cycle again.

5.1.10 Chamber Open

Description – Control senses lid is open during cycle.

Action (If lid remains closed, but alarm occurs):

1. Faulty LS4 – replace.

2. Loose connection at LS4 – repair. (Refer to Figure

5-3.)

3. Incorrect adjustment of latch flag assembly –

readjust.

Action (If lid physically opens during cycle):

1. Incorrect latch bar adjustment.

2. Chamber seal leaks – replace.

5.1 LIQUID CHEMICAL STERILIZATION CYCLE FAULTS (CONTINUED)

Loading...

Loading...