3-22 ENGINE

• Remove the oil seal

8 and spring seat

9.

#

• Remove the other valves in the same manner as described

previously.

CYLINDER HEAD DISTORTION

• Decarbonize the combustion chambers.

• Check the gasket surface of the cylinder head for distortion

with a straightedge and thickness gauge, taking a clearance

reading at several places indicated.

• If the largest reading at any position of the straightedge

exceeds the limit, replace the cylinder head.

% Cylinder head distortion:

Service Limit: 0.05 mm

$ 09900-20803: Thickness gauge

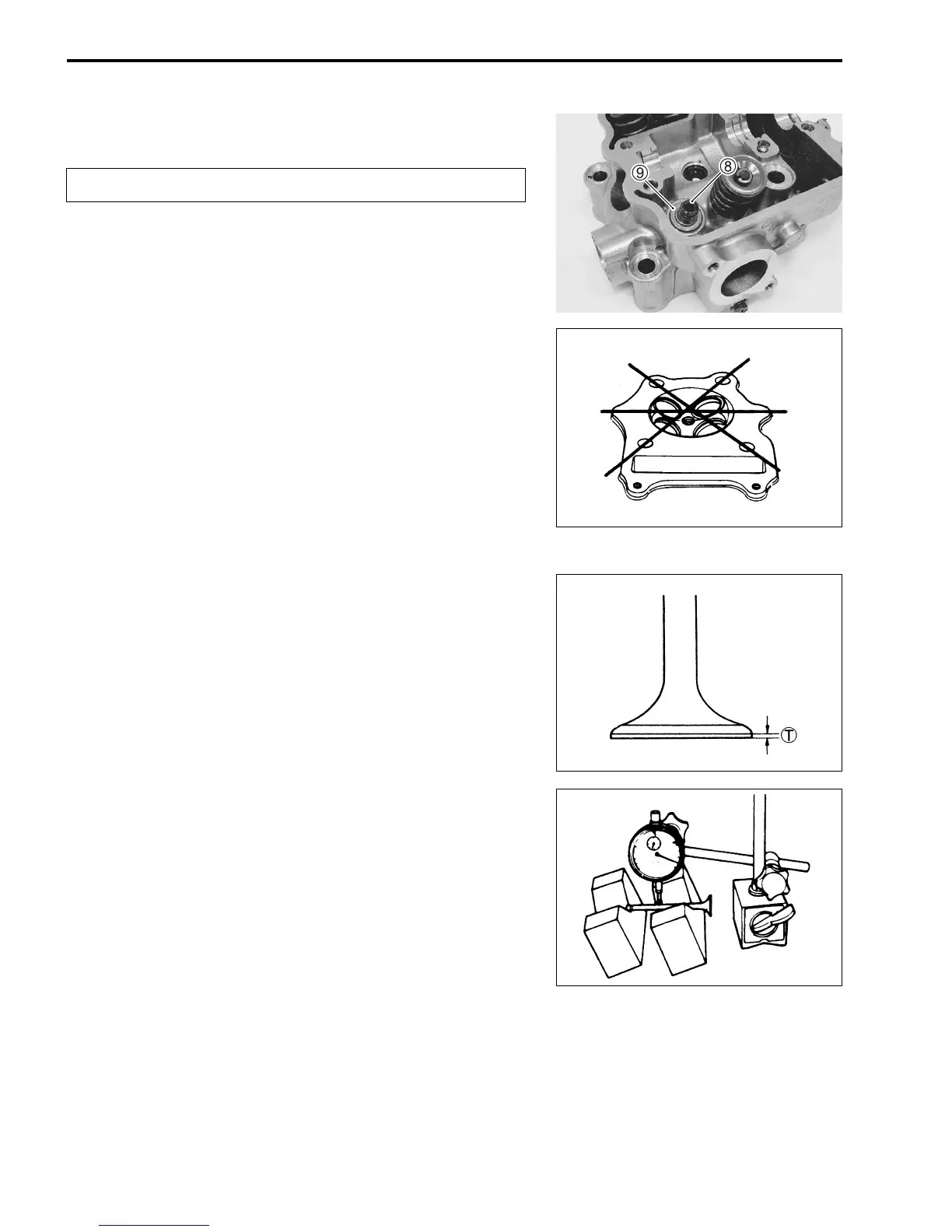

VALVE FACE WEAR

• Visually inspect each valve face for wear. Replace any valve

with an abnormally worn face. The thickness of the valve face

decreases as the face wears. Measure the valve face

T. If it

is out of specification replace the valve with a new one.

% Valve head thickness

T:

Service Limit: 0.5 mm

$ 09900-20102: Venier calipers

VALVE STEM RUNOUT

• Support the valve using V-blocks and check its runout using

the dial gauge as shown.

• If the runout exceeds the service limit, replace the valve.

% Valve stem runout:

Service Limit: 0.05 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block (100 mm)

Do not reuse the removed oil seal.

Loading...

Loading...