ENGINE 3-33

PISTON RING FREE END GAP AND PISTON RING END GAP

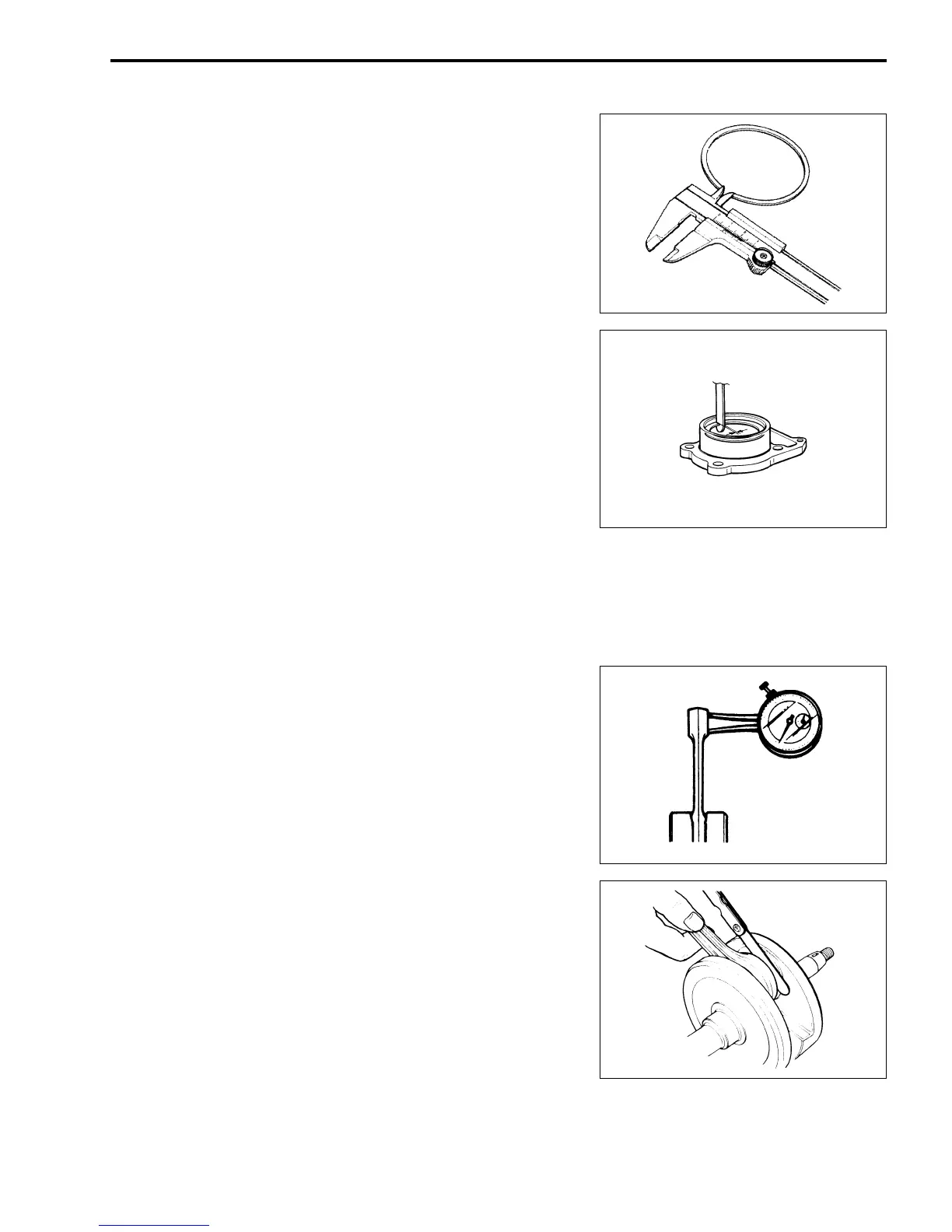

• Measure the piston ring free end gap using the vernier cali-

pers.

• Next, fit the piston ring squarely into the cylinder and measure

the piston ring end gap using the thickness gauge.

• If any of the measurements exceeds the service limit, replace

the piston ring with a new one.

% Piston ring free end gap:

Service Limit (1st) : 5.6 mm

(2nd) : 4.9 mm

$ 09900-20102: Vernier calipers

% Piston ring end gap:

Service Limit (1st) : 0.50 mm

(2nd) : 0.50 mm

$ 09900-20803: Thickness gauge

CONROD AND CRANKSHAFT

CONROD SMALL END INSIDE DIAMETER INSPECTION

• Using the dial calipers, measure the conrod small end inside

diameter both in vertical and horizontal directions. If any of the

measurements exceeds the service limit, replace the conrod.

% Conrod small end I.D.:

Service Limit: 16.040 mm

$ 09900-20605: Dial calipers (1/100 mm, 10 – 34 mm)

CONROD BIG END SIDE CLEARANCE INSPECTION

• Using a thickness gauge, measure the side clearance at the

conrod big end. If the measurement is out of standard value,

measure the conrod big end width and crank pin width individ-

ually to determine, which one is to be replaced.

% Conrod big end side clearance:

Standard: 0.10 – 0.65 mm

Service Limit: 1.0 mm

$ 09900-20803: Thickness gauge

CONROD BIG END BEARING

• Check that the conrod turns smoothly without play and noise.