ENGINE 3-31

CYLINDER

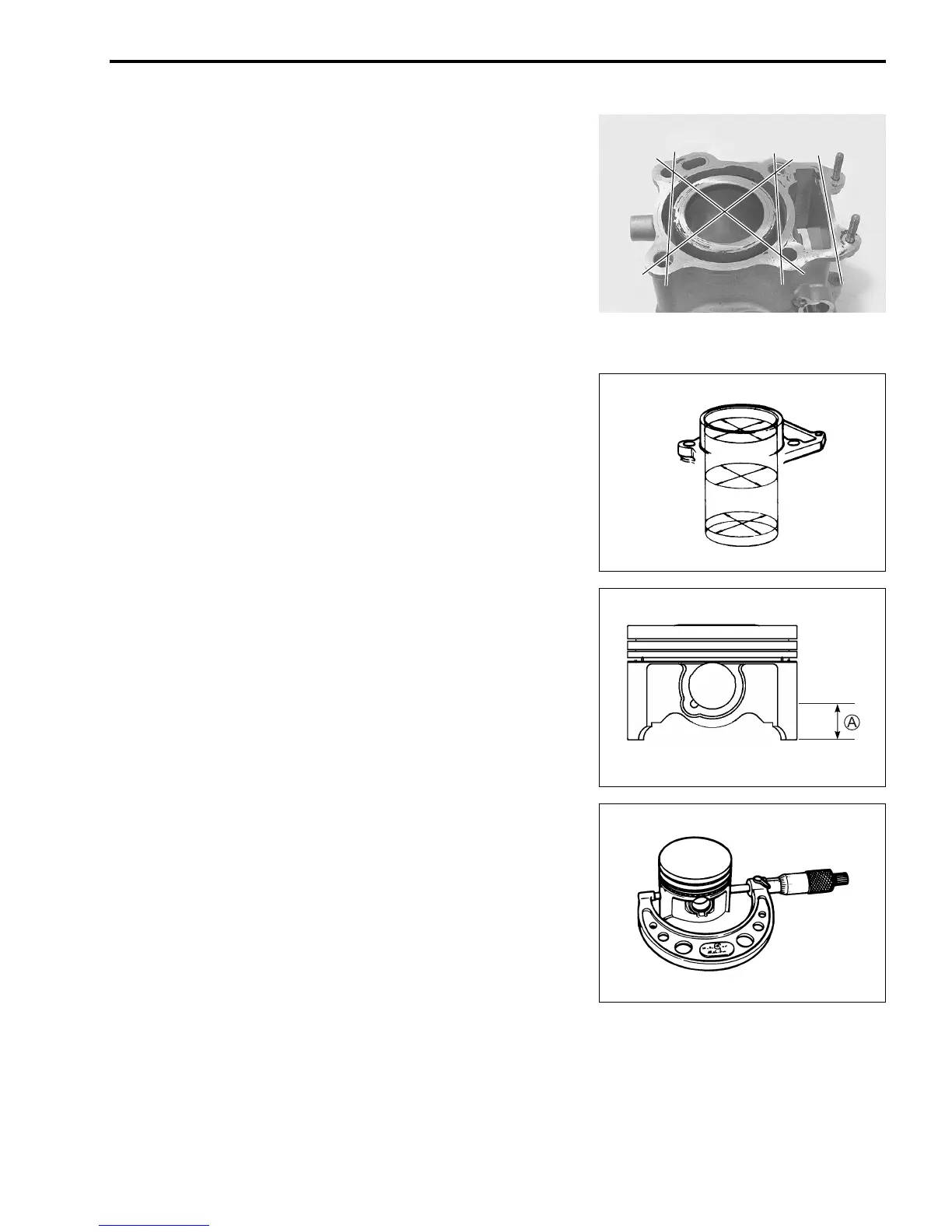

CYLINDER DISTORTION

• Check the gasket surface of the cylinder for distortion with a

straightedge and thickness gauge, taking a clearance reading

at several places as indicated.

• If the largest reading at any position of the straightedge

exceeds the limit, replace the cylinder with a new one.

! Cylinder distortion:

Service Limit: 0.05 mm

" 09900-20803: Thickness gauge

CYLINDER BORE

• Inspect the cylinder wall for any scratches, nicks or other

damage.

• Measure the cylinder bore diameter at six places.

! Cylinder bore:

Standard: 57.000 – 57.015 mm

" 09900-20530: Cylinder gauge set

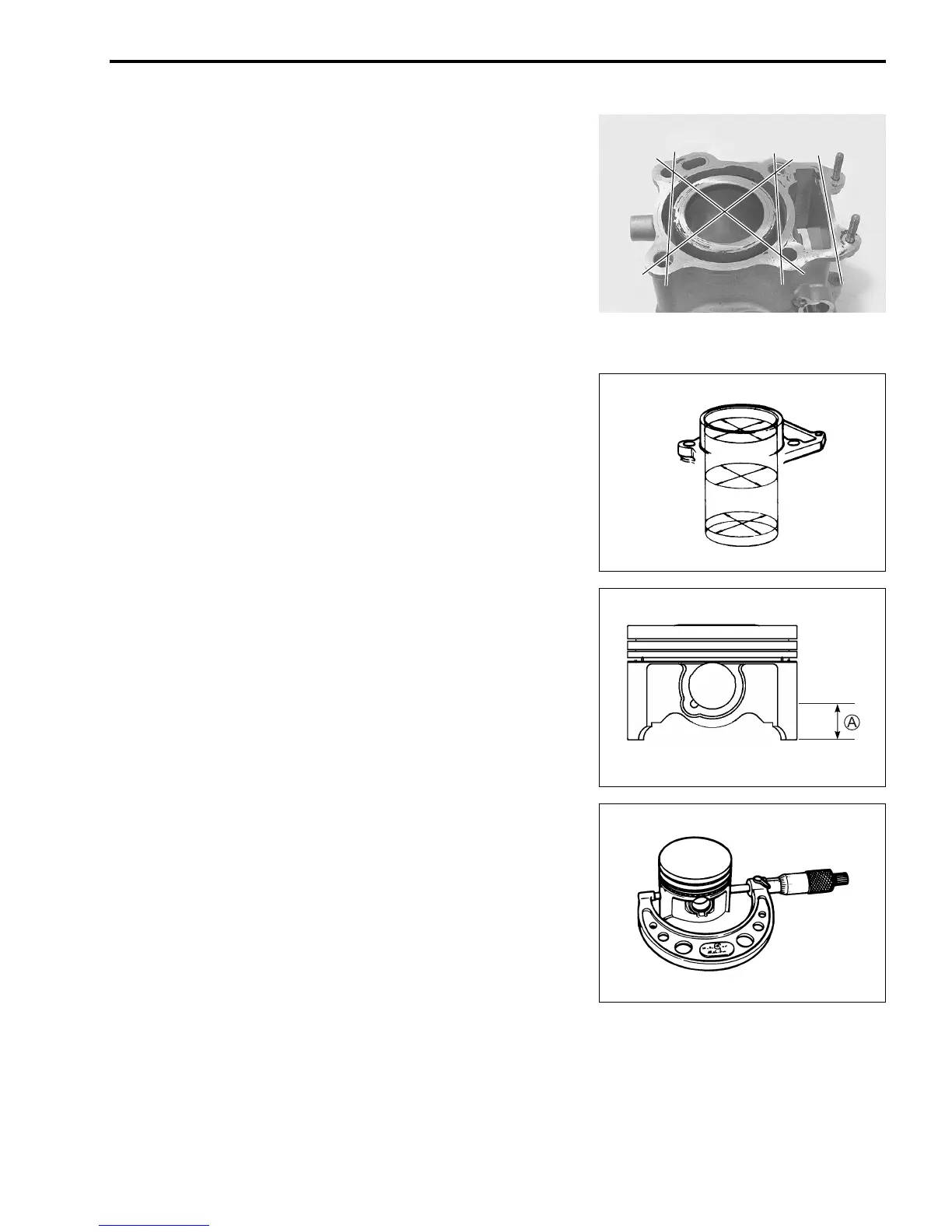

PISTON

PISTON DIAMETER

• Using a micrometer, measure the piston outside diameter at

15 mm

A from the piston skirt end.

• If the measurement is less than the limit, replace the piston.

! Piston diameter:

Service Limit: 56.880 mm

at 15 mm from the skirt end

" 09900-20203: Micrometer (50 – 75 mm)

PISTON-TO-CYLINDER CLEARANCE

• Subtract the piston diameter from the cylinder bore diameter.

• If the piston-to-cylinder clearance exceeds the service limit,

replace the cylinder or the piston, or both.

! Piston-to-cylinder clearance:

Service Limit: 0.120 mm

Loading...

Loading...