3-34 ENGINE

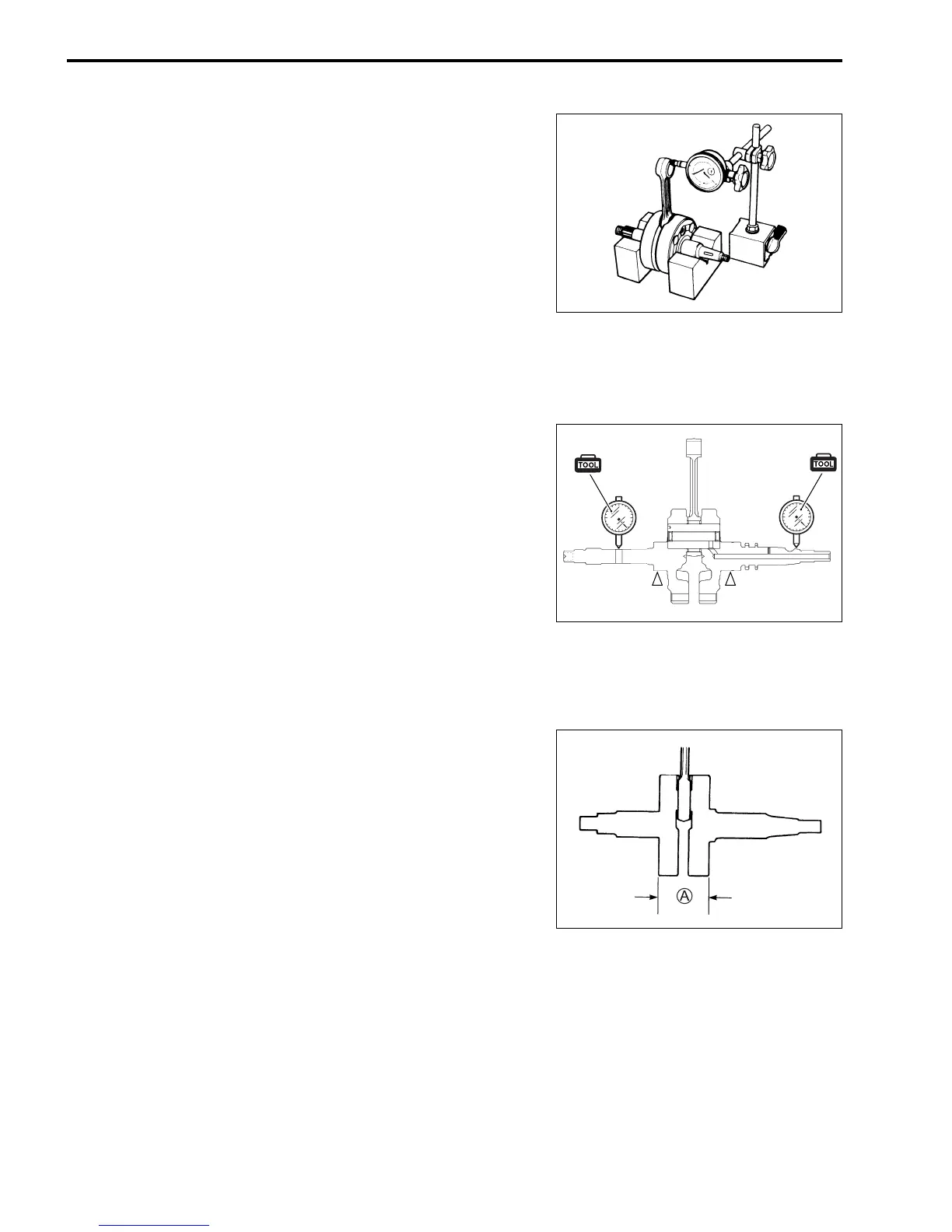

CONROD DEFLECTION INSPECTION

• Move the small end sideways while holding the big end

immovable in thrust direction.

• Measure the amount of deflection.

• Turn the conrod and see if it moves smoothly without play and

noise.

• This method can check the extent of wear on the parts of the

conrod’s big end.

% Conrod deflection:

Service Limit: 3.0 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block (100 mm)

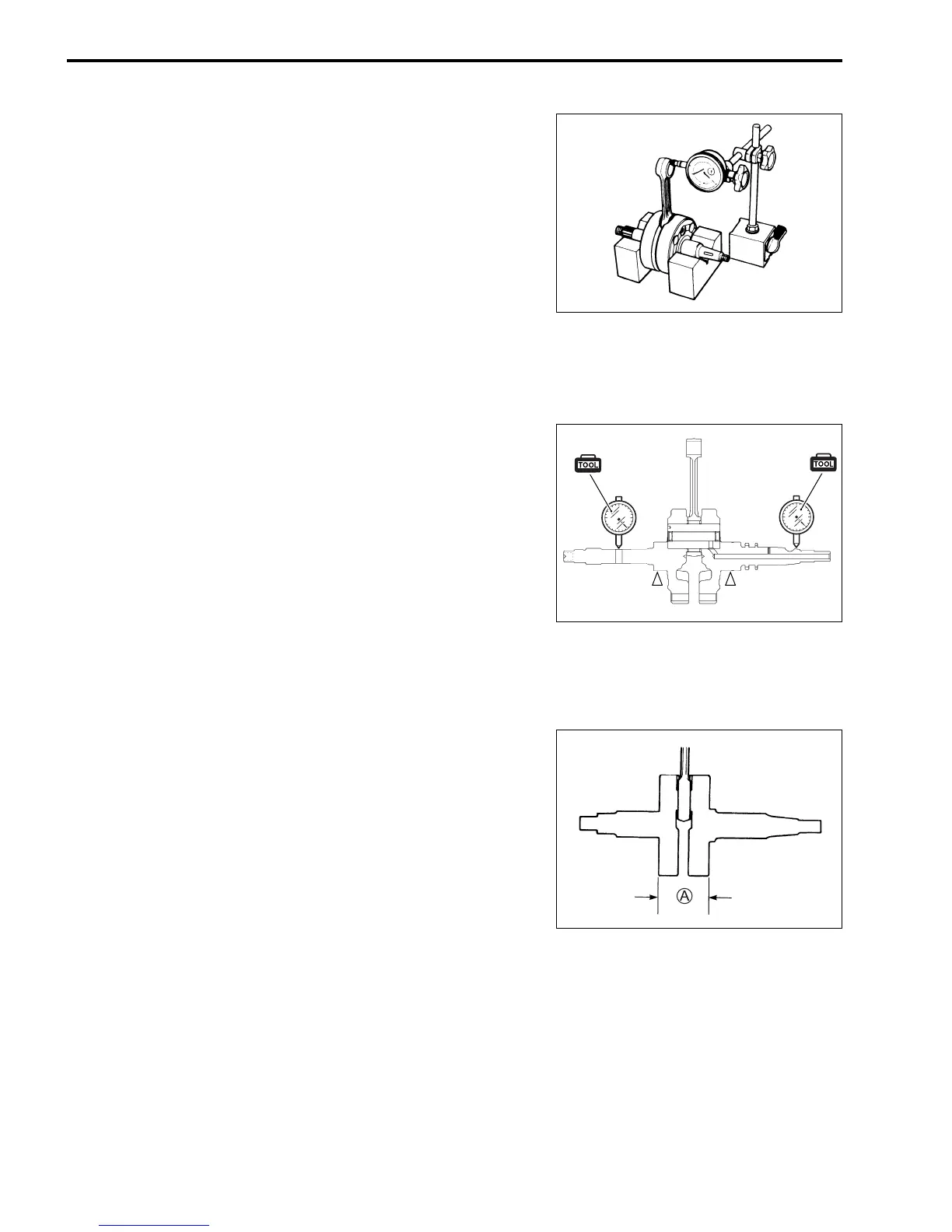

CRANKSHAFT RUNOUT INSPECTION

• With the right and left crank journals supported with V-block,

turn the crankshaft slowly. At this time, measure the crank-

shaft end runout using a dial gauge. If the runout exceeds the

service limit, replace the crankshaft.

% Crankshaft runout:

Service Limit: 0.10 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block (100 mm)

NOTE:

Set the V-blocks so that the crankshaft becomes horizontal.

WIDTH BETWEEN CRANKSHAFT WEBS

• Measure the width between crankshaft webs

A.

% Width between crankshaft webs

A:

Standard: 63.9 – 64.1 mm

Loading...

Loading...