ENGINE 3-67

ENGINE REASSEMBLY

• Reassemble the engine in the reverse order of disassembly.

• The following steps require special attention or precautionary

measures should be taken.

NOTE:

Apply engine oil to each running and sliding part before reassem-

bling.

• Be sure to install the following items to the crankcase.

* Crankshaft journal bearing ( 3-63)

* Gearshift fork ( 3-57)

* Gearshift fork shaft ( 3-57)

* Gearshift shaft bearing ( 3-56)

* Gearshift cam bearing ( 3-56)

* Gearshift fork bearing ( 3-56)

* Gearshift cam ( 3-56)

* Bearing retainer ( 3-57)

* Oil jets ( 3-59)

PISTON AND CONROD

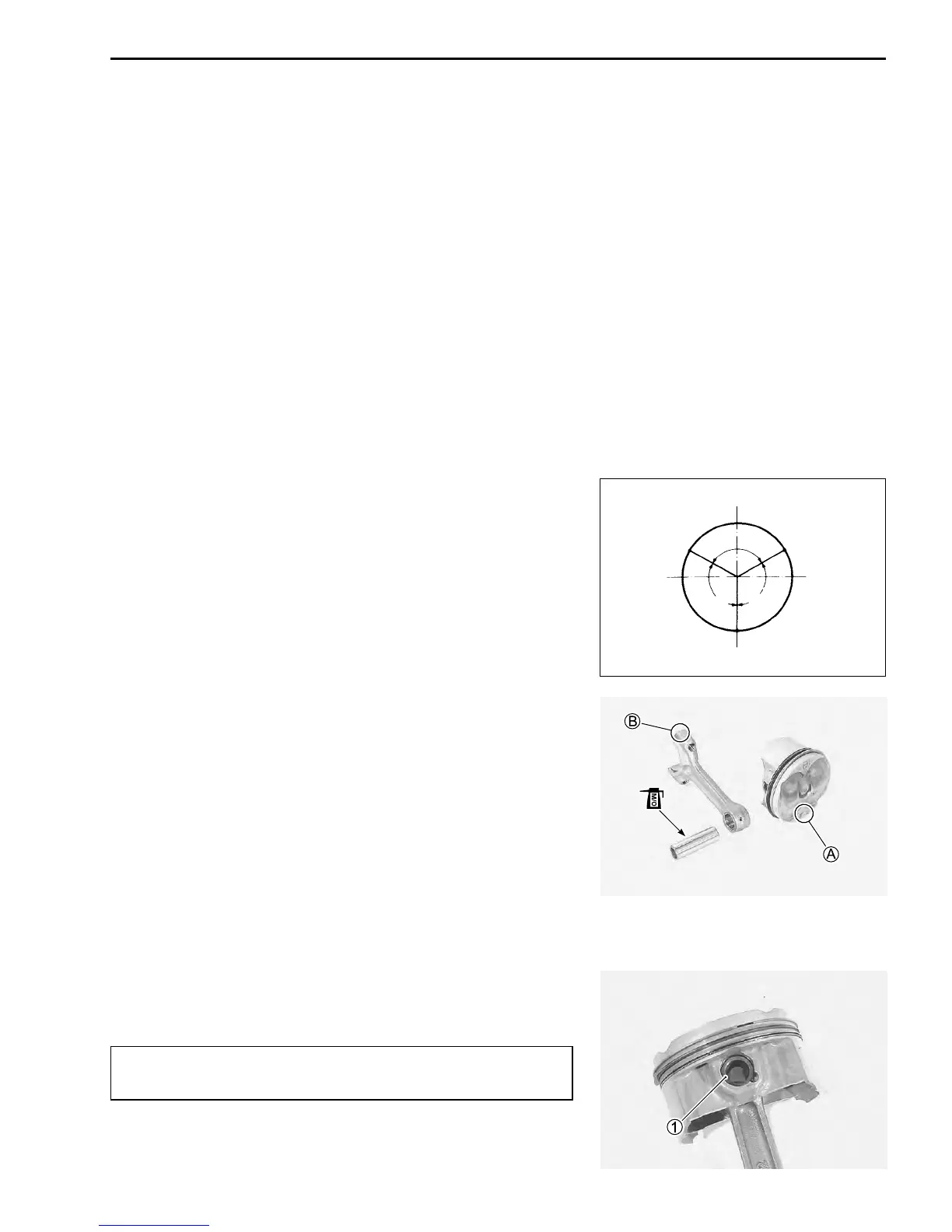

• Position the gaps of the three rings as shown. Before inserting

each piston into the cylinder, check that the gaps are so located.

• Rub a small quantity of molybdenum oil solution onto each pis-

ton pin.

OO

OO

O MOLYBDENUM OIL

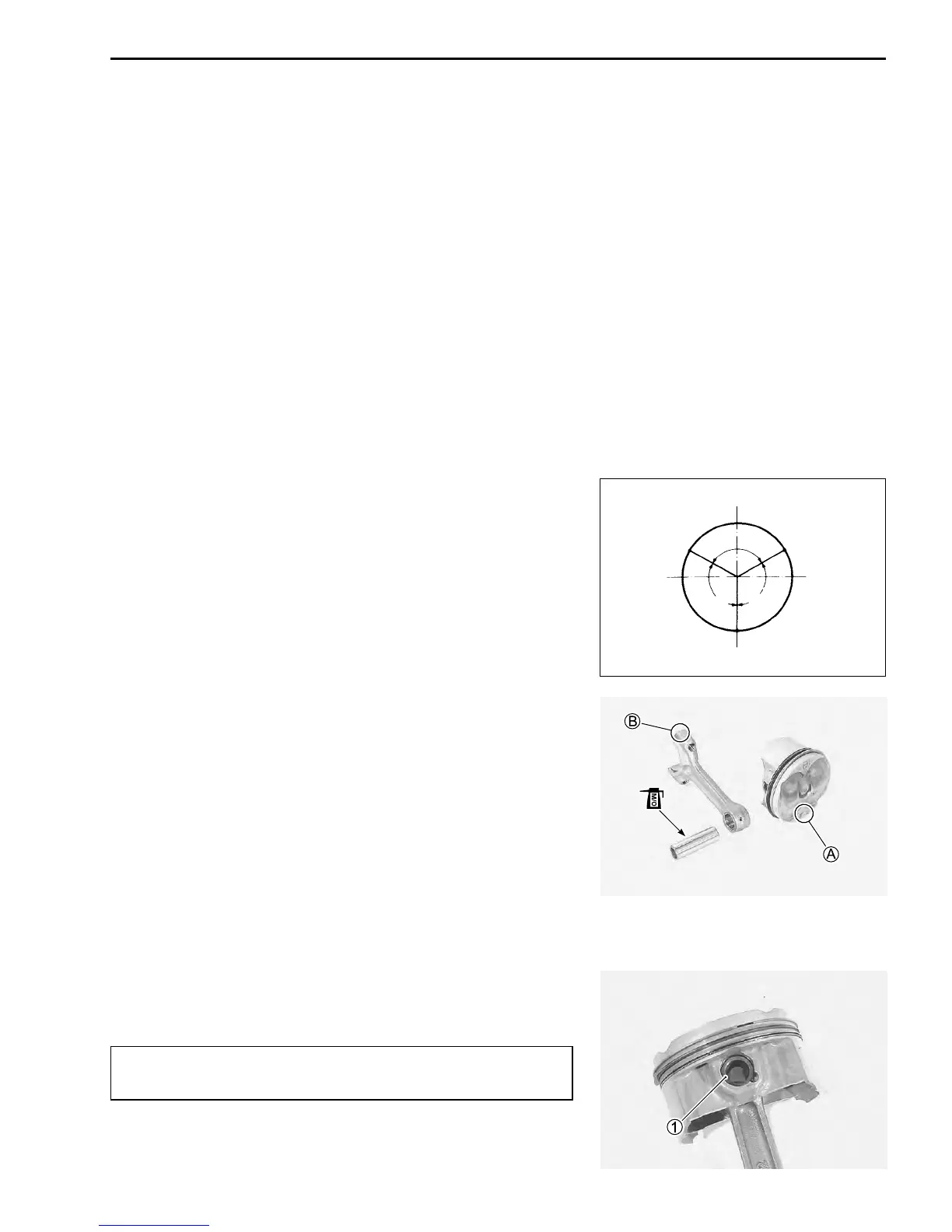

• Assemble the piston and conrod.

NOTE:

When installing the pistons, the indent

A

on the piston head must

be faced to another side of ID code

B

on conrod face.

• Install the pistons.

NOTE:

Be sure to install the pistons in the cylinders from which they were

removed in disassembly, refer to the cylinder numbers, “1” through

“4”, scribed on the piston.

• Install the piston pin circlips 1.

#

Use new piston pin circlips to prevent circlip failure which

will occur with a bend one.

NOTE:

End gap of the circlip should not be aligned with the cutaway in the

piston pin bore.

• Apply engine oil to the sliding surface of the pistons and cylin-

• 2nd ring

• Lower side

rail

• Upper side

rail

• Top ring

• Spacer

EX

IN

120°

120°

120°

Loading...

Loading...