Transfer: 3C-6

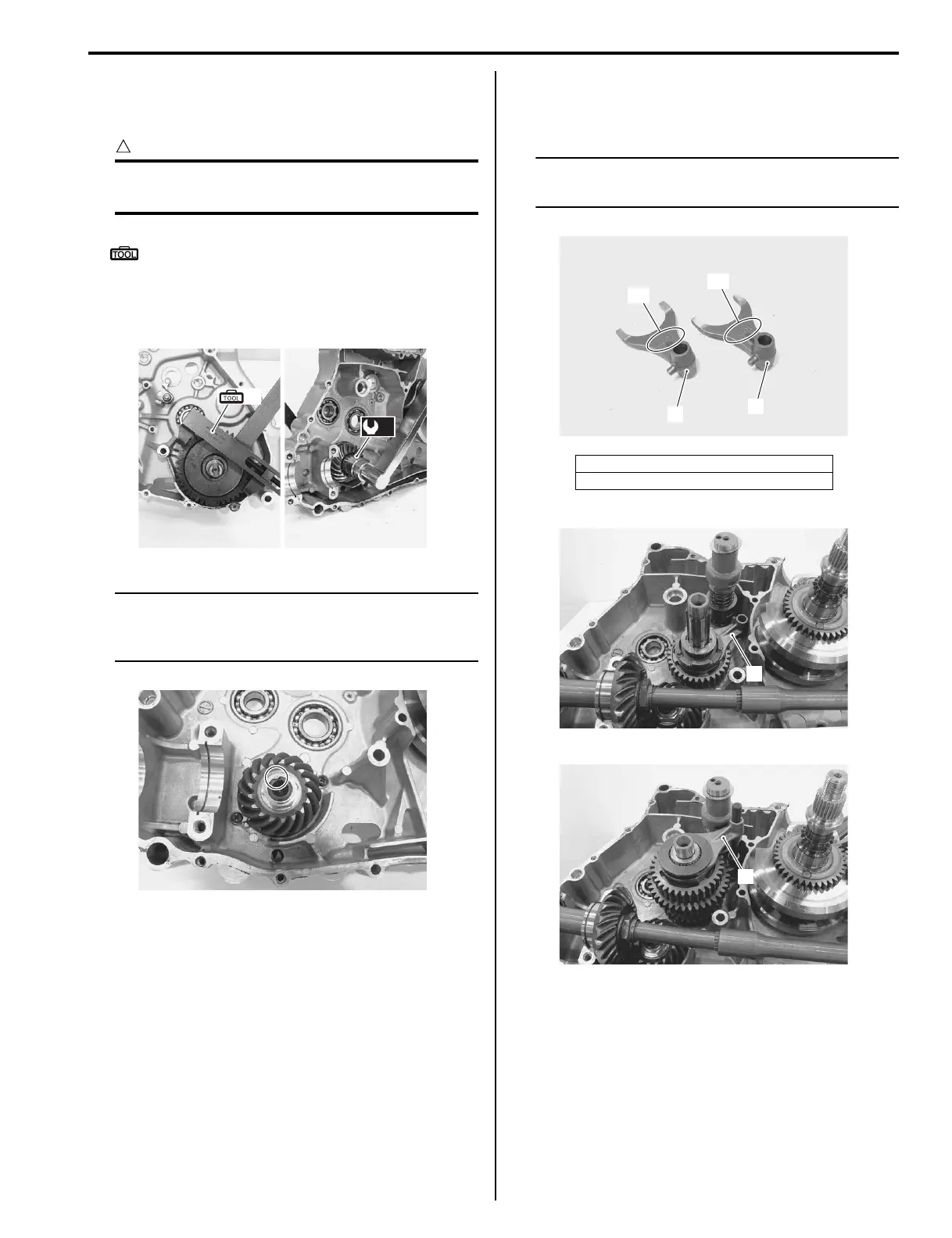

• Hold the transfer driven gear with the special tool and

tighten the drive bevel gear nut to the specified

torque.

CAUTION

!

The removed drive bevel gear nut must be

replaced with a new one.

Special tool

(A): 09920–53740 (Clutch sleeve hub holder)

Tightening torque

Drive bevel gear nut (a): 100 N·m (10.0 kgf-m,

72.5 lb-ft)

NOTE

After the backlash and tooth contact have

been checked or adjusted, stake the nut with

a center punch.

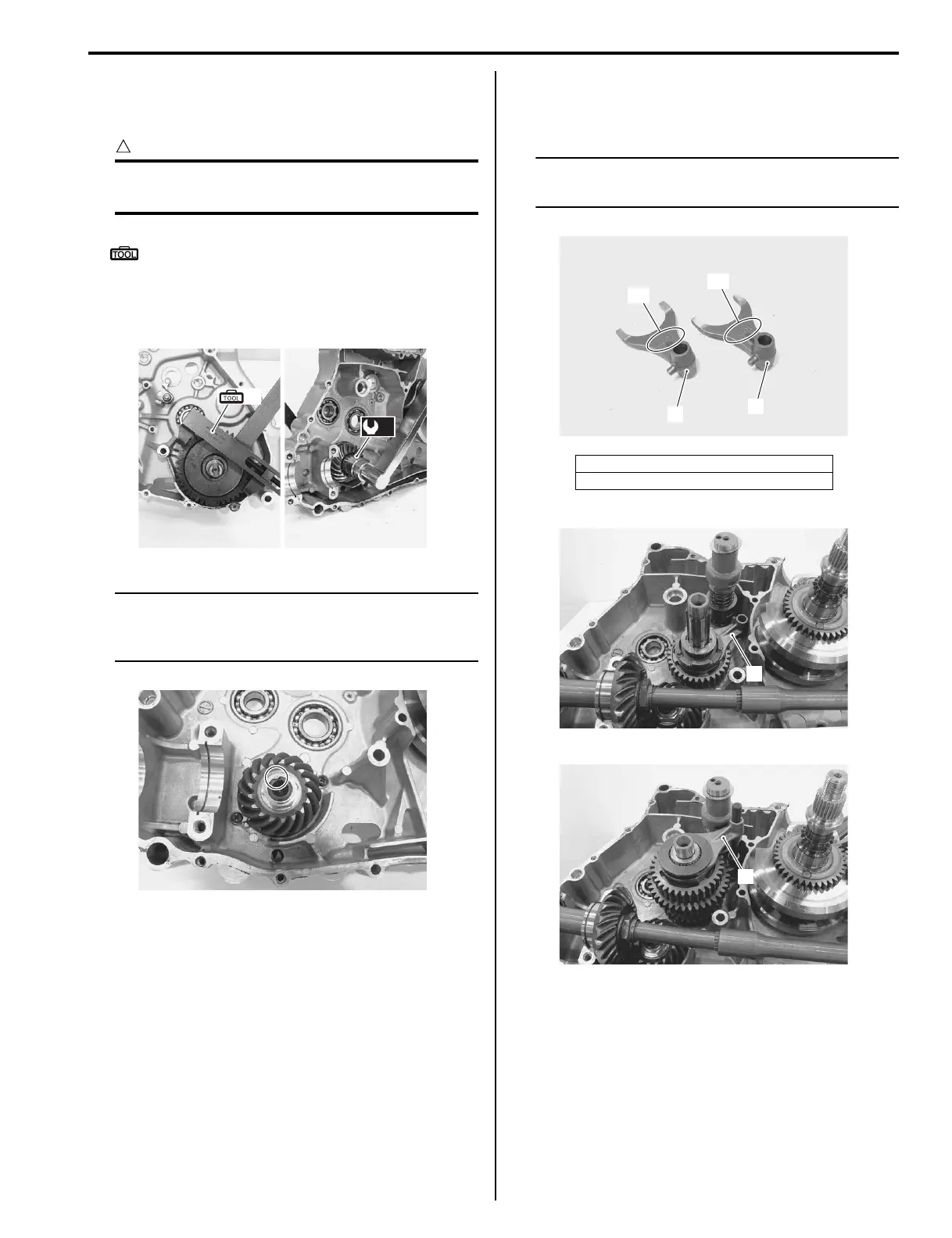

• Install the transfer gearshift cam assembly.

• Install the gearshift fork (5), reverse gearshift fork (6)

and transfer counter shaft assembly. Refer to

“Transfer Construction (LT-A400/F) (Page 3C-8)”.

NOTE

Each gearshift fork has own embossed

letters “A” or “B”.

• Install the reverse idle gear assembly. Refer to

“Transfer Construction (LT-A400/F) (Page 3C-8)”.

• Assemble the engine. Refer to “Engine Bottom Side

Assembly in Section 1D (Page 1D-43)”.

• Remount engine assembly. Refer to “Engine

Assembly Installation in Section 1D (Page 1D-9)” and

“Engine Top Side Assembly in Section 1D (Page 1D-

13)”.

(A)

(a)

I827H1330013-01

I827H1330014-01

“A”: 44D-TM (for high/low gears)

“B”: 44D-TL (for reverse gear)

5

6

“A”

“B”

I827H1330015-01

5

I827H1330016-01

6

I827H1330017-01

Loading...

Loading...