1D-85 Engine Mechanical:

Installation

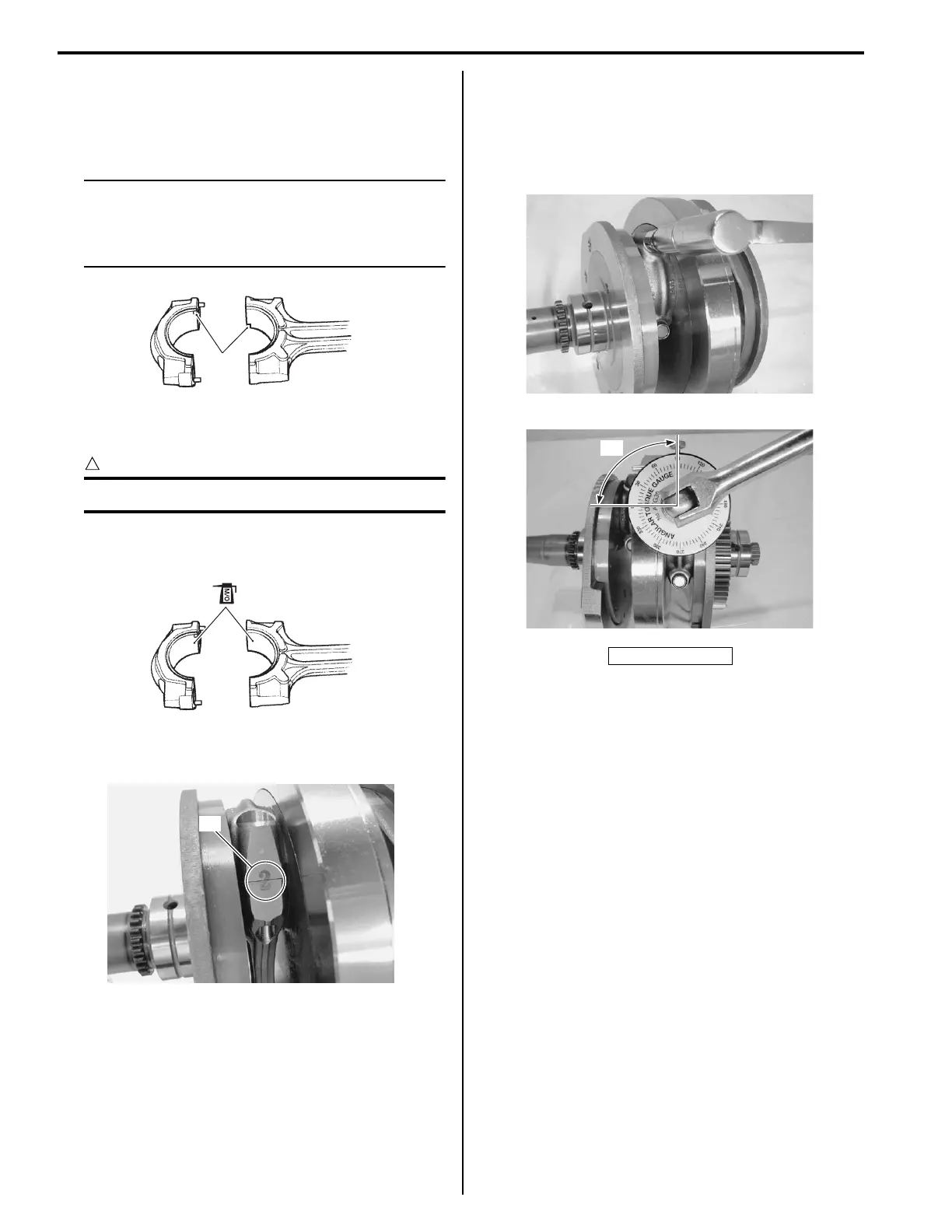

1) When installing the bearings into the conrod cap and

conrod, be sure to fix the stopper part “A” first, and

then press in the opposite side of the bearing.

NOTE

Inspect and select the conrod crank pin

bearing if necessary. Refer to “Conrod Crank

Pin Bearing Inspection and Selection

(Page 1D-86)”.

2) Apply molybdenum oil solution to the crank pin and

bearing surface.

CAUTION

!

Be sure to clean the conrod big end.

M/O: Molybdenum oil (Molybdenum oil

solution)

3) When fitting the conrod cap, make sure that I.D.

code “B” on each conrod faces intake side.

4) Apply engine oil to the conrod cap bolts.

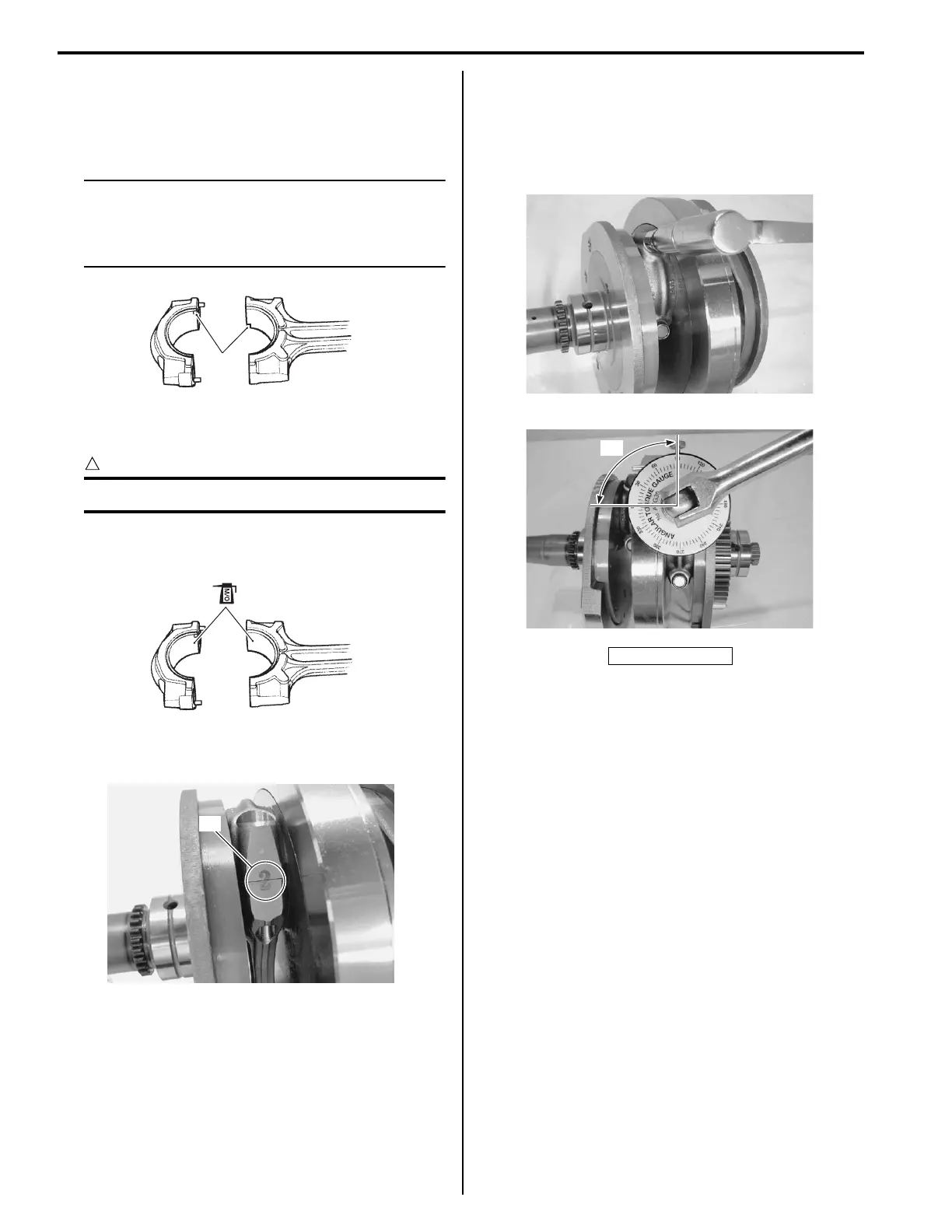

5) Tighten the conrod cap bolts as following two steps.

Tightening torque

Conrod cap bolt: 35 N⋅m (3.5 kgf-m, 25.5 Ib-ft)

then turn in 1/4 (90°) turn

6) Check that the conrod moves smoothly.

7) Install the crankshaft assembly to the crankcase.

Refer to “Engine Bottom Side Assembly (Page 1D-

68)”.

“A”

I717H1140221-02

I718H1140273-01

“B”

I822H1140288-01

“a”: 90°

I822H1140289-01

“a”

I822H1140290-01

Loading...

Loading...