131

Refrigeration Maintenance and Service

Operations

NOTE: The following procedures involve

servicing the refrigeration system. Some of these

service procedures are regulated by Federal, and

in some cases, by State and Local laws.

All regulated refrigeration service procedures

must be performed by an EPA certified

technician, using approved equipment and

complying with all Federal, State and Local

laws.

NOTE: Replace the one-piece filter drier when

major system contamination requires evacuation

and cleanup of the refrigeration system.

Service Tools

Unit Service Fittings

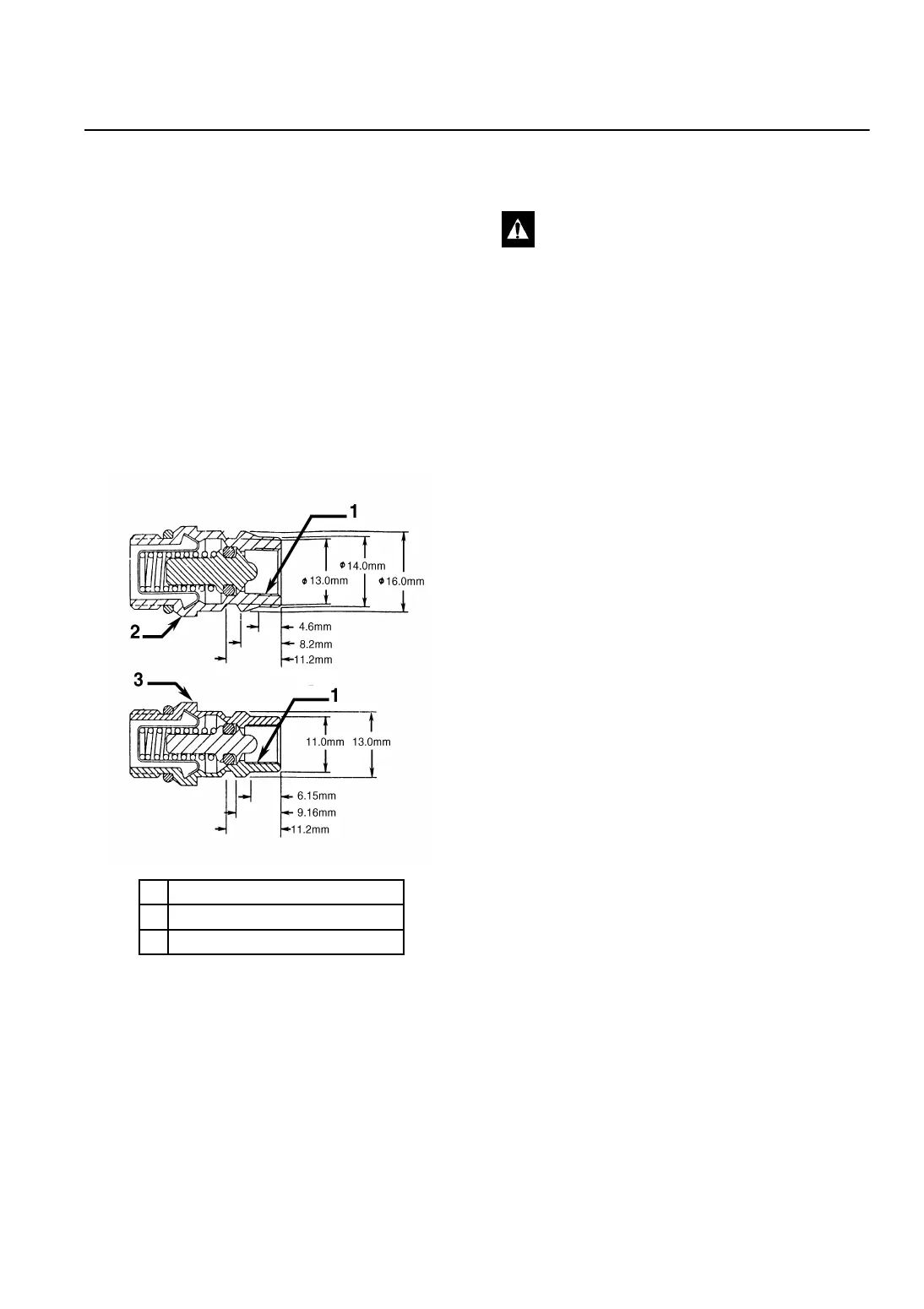

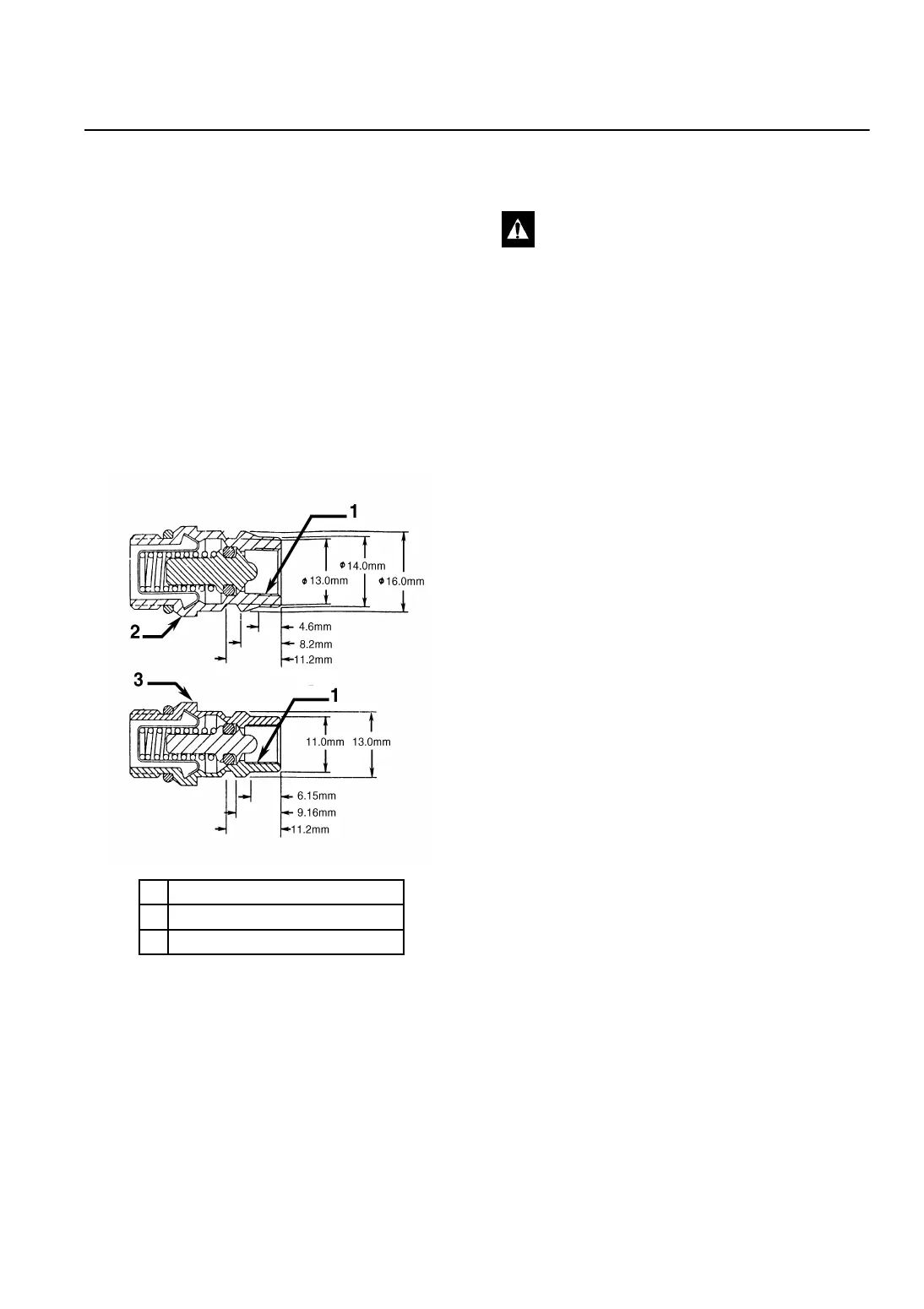

Special fittings are used on R-404A systems to

prevent mixing of non-HFC refrigerants in

R-134A units. These fittings are located in three

places on CRR refrigeration systems:

• Low side near the compressor suction service

valve (or suction adapter),

• High side near the compressor discharge

service valve (or discharge manifold),

Leak Detection

Leaks can be detected with the use of soap

bubbles and with Halogen leak detectors such as

model H10G, or model H10N (portable).

Gauge Manifold Set

A new gauge manifold set (refer to Tool Catalog)

should be dedicated for use with R-134a only.

Gauge hoses should also be dedicated to R-404A.

1. Internal Threads for Cap

2. High Pressure Fitting

3. Low Pressure Fitting

Figure 37: Service Fittings Specifications

AXA0175

CAUTION: When servicing Thermo King

R-404A refrigeration systems, use only

those service tools (i.e., vacuum pump,

refrigerant recovery equipment, gauge

hoses, and gauge manifold set) certified

for and dedicated to R-404A refrigerant

and Polyol Ester based compressor oils.

Residual non-HFC refrigerants or

non-Ester based oils will contaminate

HFC systems.

Loading...

Loading...