Refrigeration Maintenance and Service Operations

135

Gauge Manifold Set Removal

NOTE: To ensure minimum refrigerant release

to the atmosphere, THE SYSTEM SHOULD BE

RUNNING. However, this is not possible in all

cases, but the same procedure should be

followed.

1. Rotate discharge hose fitting hand wheel

counterclockwise to withdraw the fitting stem

from the discharge line port valve. Then open

both service manifold valves to center port.

2. Operate the unit on Cool using the

“CAPACITY 100%” test from the Manual

Function Test menu of the controller.

3. Rotate the suction hose coupler hand wheel

counterclockwise to withdraw the fitting stem

from the suction line port valve. Then turn the

unit off.

4. Remove the gauge lines from the suction and

discharge service fittings and cap the service

ports.

5. Secure all manifold lines to manifold hose

anchors when the manifold is not in use.

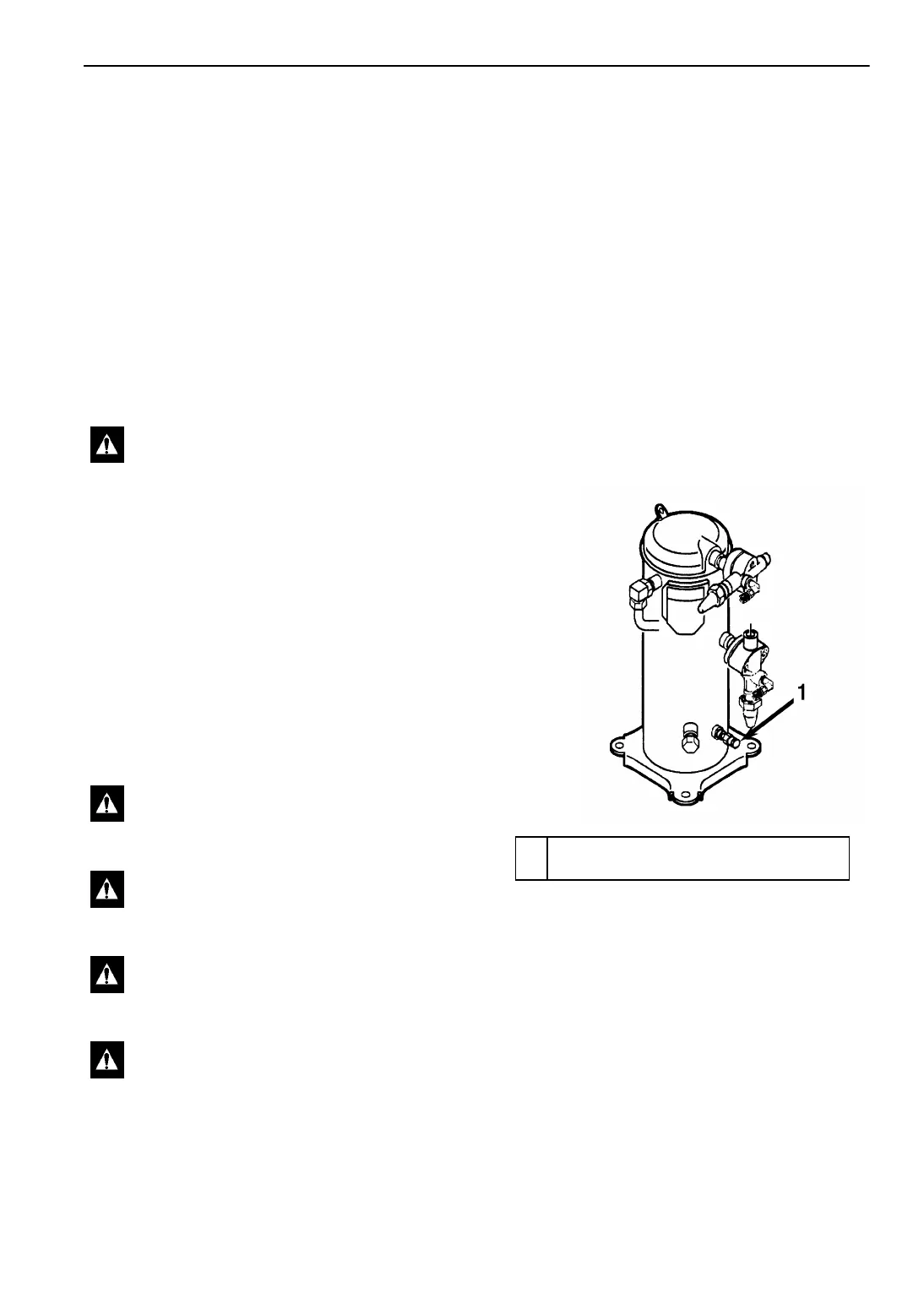

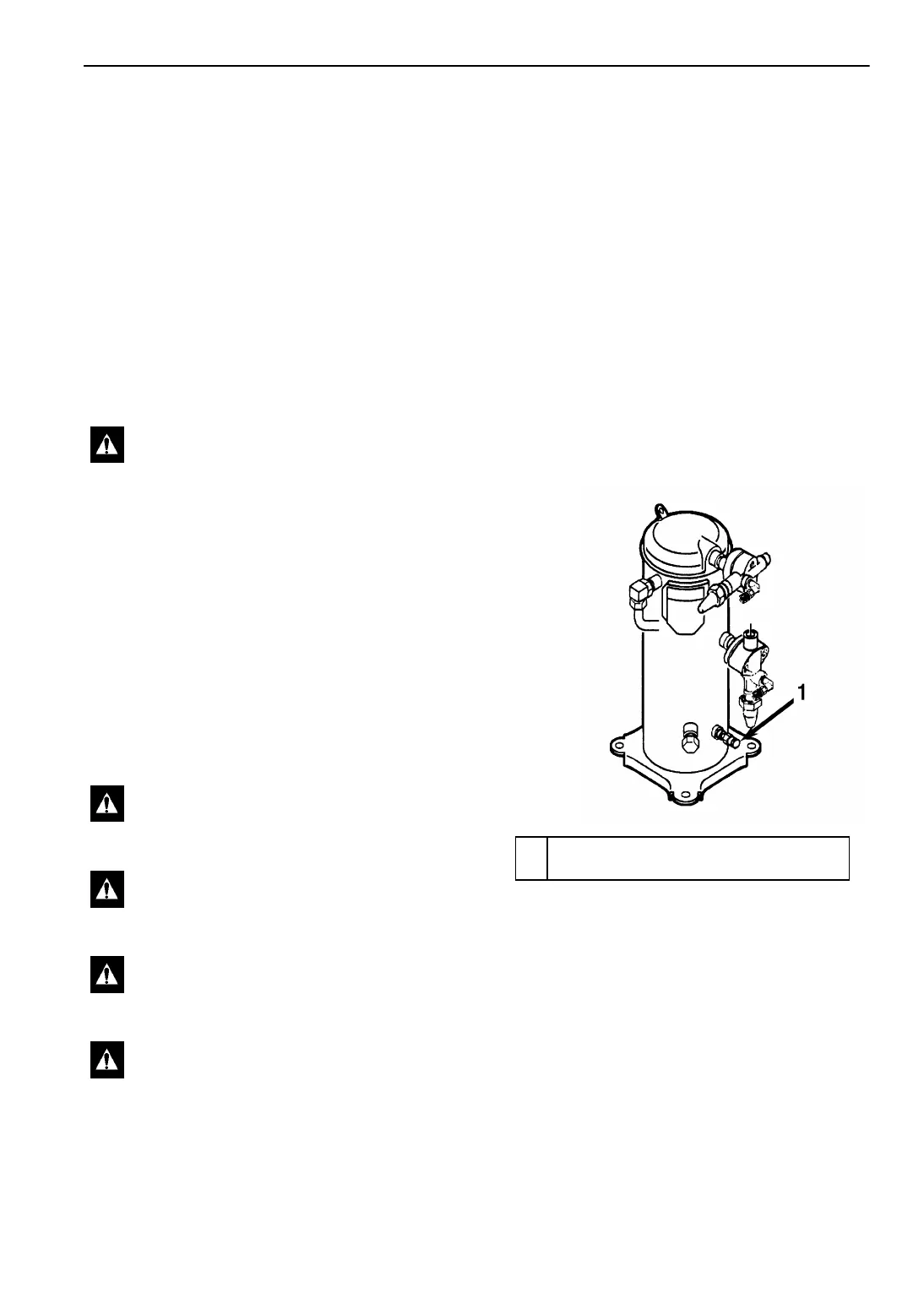

Checking Compressor Oil

The compressor oil should be checked during

pre-trip inspections and when there is evidence of

oil loss (oil leaks) or when components in the

refrigeration system have been removed for

service or replacement.

To Check Compressor Oil Level with

an Ambient Air Temperature Above

10 C (50 F)

Install gauge manifold on the compressor. Operate

the unit on Cool with a 138 kPa, 1.38 bar, 20 psig

minimum suction pressure and a 689 kPa, 6.89

bar, 100 psig discharge pressure for 15 minutes or

more. After the unit has maintained the above

conditions for 15 minutes, observe the compressor

oil level. The oil should be 1/2 to 3/4 up in the

sight glass.

To Check Compressor Oil Level with

an Ambient Air Temperature Below

10 C (50 F)

With the evaporator temperature below 10 C

(50 F), initiate a Manual Defrost to operate the

unit through a complete Defrost cycle. After

completing the defrost cycle, operate the unit on

Cool for a few minutes. After 2 to 3 minutes,

observe the oil level. The oil should be 1/2 to 3/4

up in the sight glass.

If the container is empty, you can operate the unit

on the heat cycle instead of the defrost cycle.

CAUTION: Rubber gloves are

recommended when handling Ester based

compressor oil.

CAUTION: Use ONLY Polyol Ester based

refrigeration compressor oil, refer to Tool

Catalog.

CAUTION: DO NOT mix Polyol Ester

based and standard synthetic compressor

oils.

CAUTION: Rubber gloves are

recommended when handling Ester based

compressor oil.

CAUTION: Keep Polyol Ester based

compressor oil in tightly sealed

containers. If Ester based oil becomes

contaminated with moisture or standard

oils, dispose of properly — DO NOT USE!

1.

Add and Remove Compressor Oil at the

Compressor Oil Fitting

Figure 47: Adjusting Compressor Oil Level

AXA0245

Loading...

Loading...