3

© 2009 - 2011 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO555/655/755/855

COPY PROCESS

3 - 1

3. COPY PROCESS

3.1 General Description

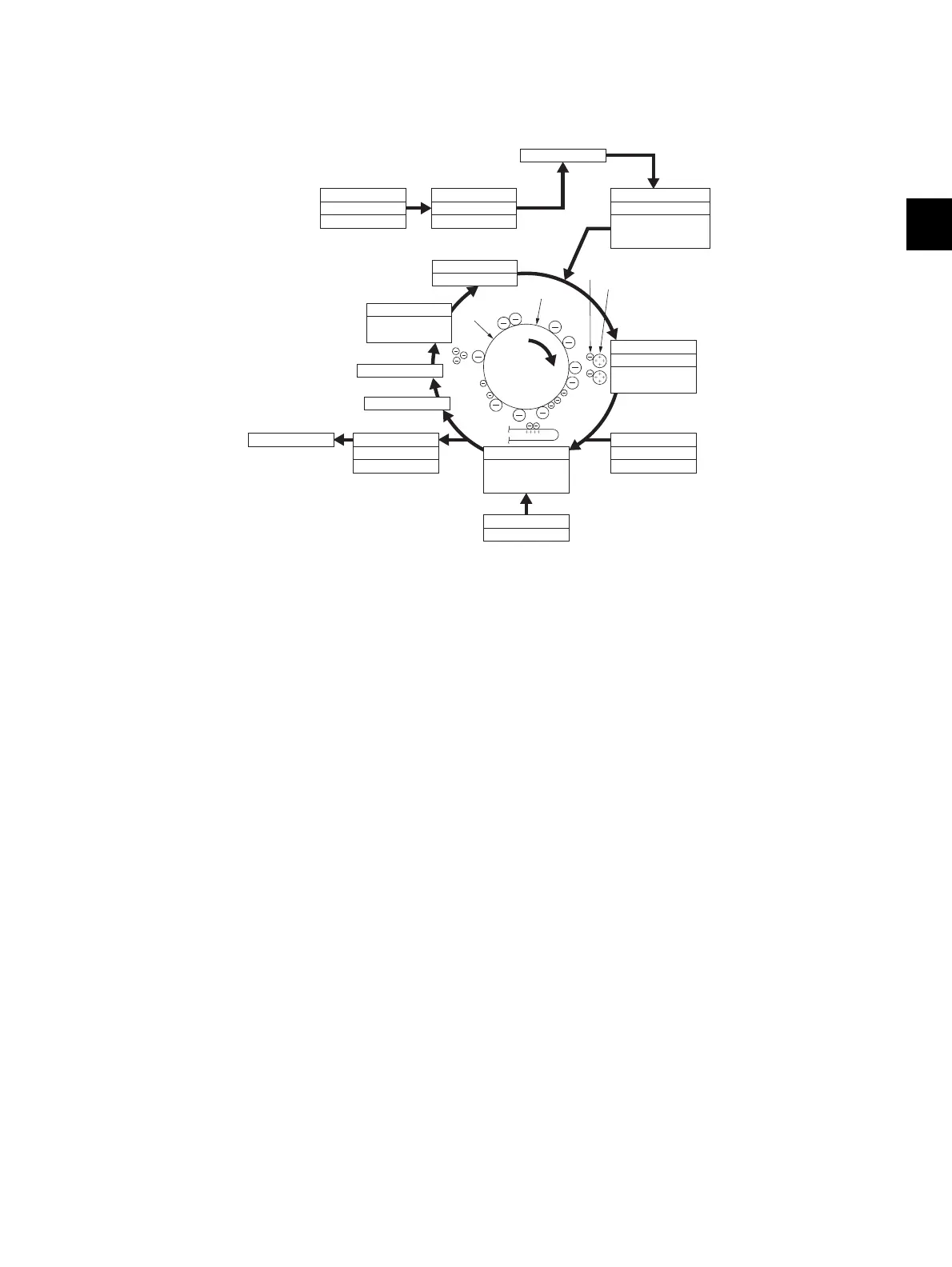

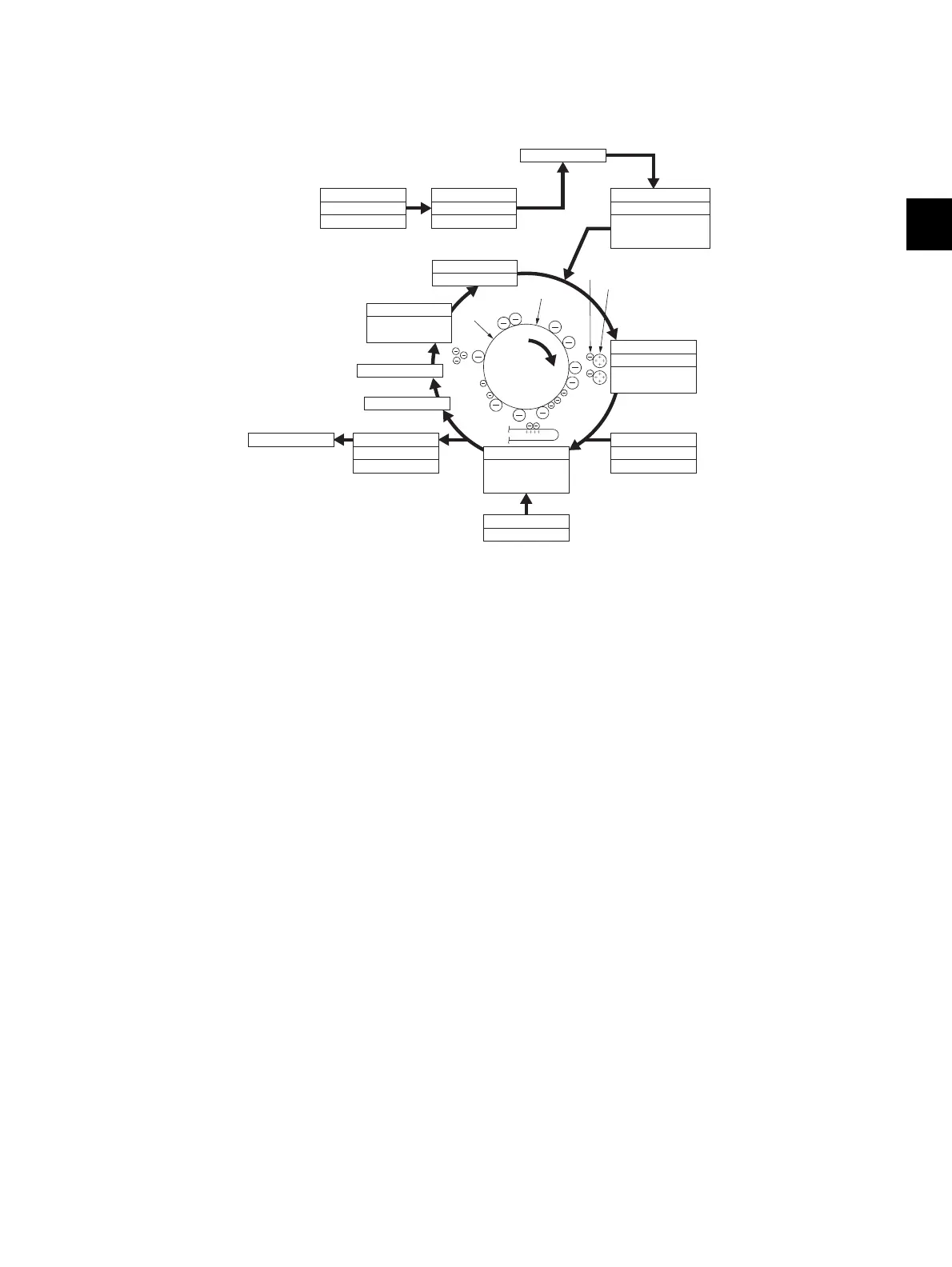

Fig. 3-1

(1) Charging:

Negatively charges the surface of the

photoconductive drum.

↓

(6) Transfer:

Transfers the visible image on the

photoconductive drum onto paper.

Separation:

Separates the paper from the drum

together with the toner.

↓

(2) Original exposure:

Converts images on the original into optical

signals.

↓

(7) Fusing:

Fuses the toner onto the paper by applying

heat and pressure.

↓

(3) Scanning:

Converts image optical signals into

electrical signals.

↓

(8) Brush cleaning:

Cleans dirt and paper dust on the drum.

↓

(4) Writing:

Converts image electrical signals into

optical signals (laser emission) and

exposes them to the surface of the

photoconductive drum.

↓

(9) Blade cleaning:

Forcibly removes the residual toner on the

drum.

↓

(5) Development:

Makes the negatively-charged toner

adhere to the photoconductive drum and

forms a visible image.

↓

(10)Discharging:

Discharges any remaining negative charge

on the drum.

Scanning

CCD

600 dpi,7500 pixel

(

3

)

Original exposure

Xenon lamp

29W

(

2

)

Image processing

Bypass feeding

Discharge

LED array

(

Wavelength 660nm x14pcs

)

-500V

(

-300V~-900V

)

(

10

)

Drawer feeding

LCF feeding

FusingDischarging

Fuser roller

700~1450W

(

4

)

Writing

Semiconductive laser

Pw=3.9 nJ/mm

2

(

555/655

)

Pw=3.0 nJ/mm

2

(755/855)

(

9

)

(

1

)

Charging

(

grid voltage

)

Bias

-394V

(

-200~-800

)

DC+AC

5 µA

(

5

)

(

6

)

(

7

)

Development

Magnetic roller

Transfer/Separation

Cleaning brush + Blade

Blade cleaning

(

8

)

Brush cleaning

Toner

Carrier

70 µA

(555/655/755)

85 µA

(855)

Loading...

Loading...