Spring

Wheel

SPRING

WHEEL-Mk.

2

This wheel has been designed to operate over long periods without maintenance.

it

will be noted that there

is

no provision for greasing, as before the wheel is assembled.

the bearings and other working surfaces are fully loaded with grease sufficient for

20,000 miles (30,000 kms.).

In view of the above and the special equipment required to dismantle the spring

wheel for rectification, owners are strongly advised to return the wheel to their

dealer, or direct to our Service Department, when attention

Is

needed.

The following instructions a;e given however, for owners who wish to carry out

their own maintenance and repairs. No attempt should be made

td

dlsmantlethe

plunger guide box without the aid of the special jig illustrated on page

136.

REMOVAL OF THE WHEEL FROM THE FRAME

Mudguard.

Disconnect the rear light leads under the saddle.

Remove the bolts

connecting the rear section mudguard to the frame and lift the mudguard away.

It

is unnecessary to disturb the mudguard of the

TR5

model in order to remove the

wheel.

Chain.

Disconnect the spring link from the rear chain and disengage from the

sprocket. Engage a gear to prevent the chain rolling off the sprocket.

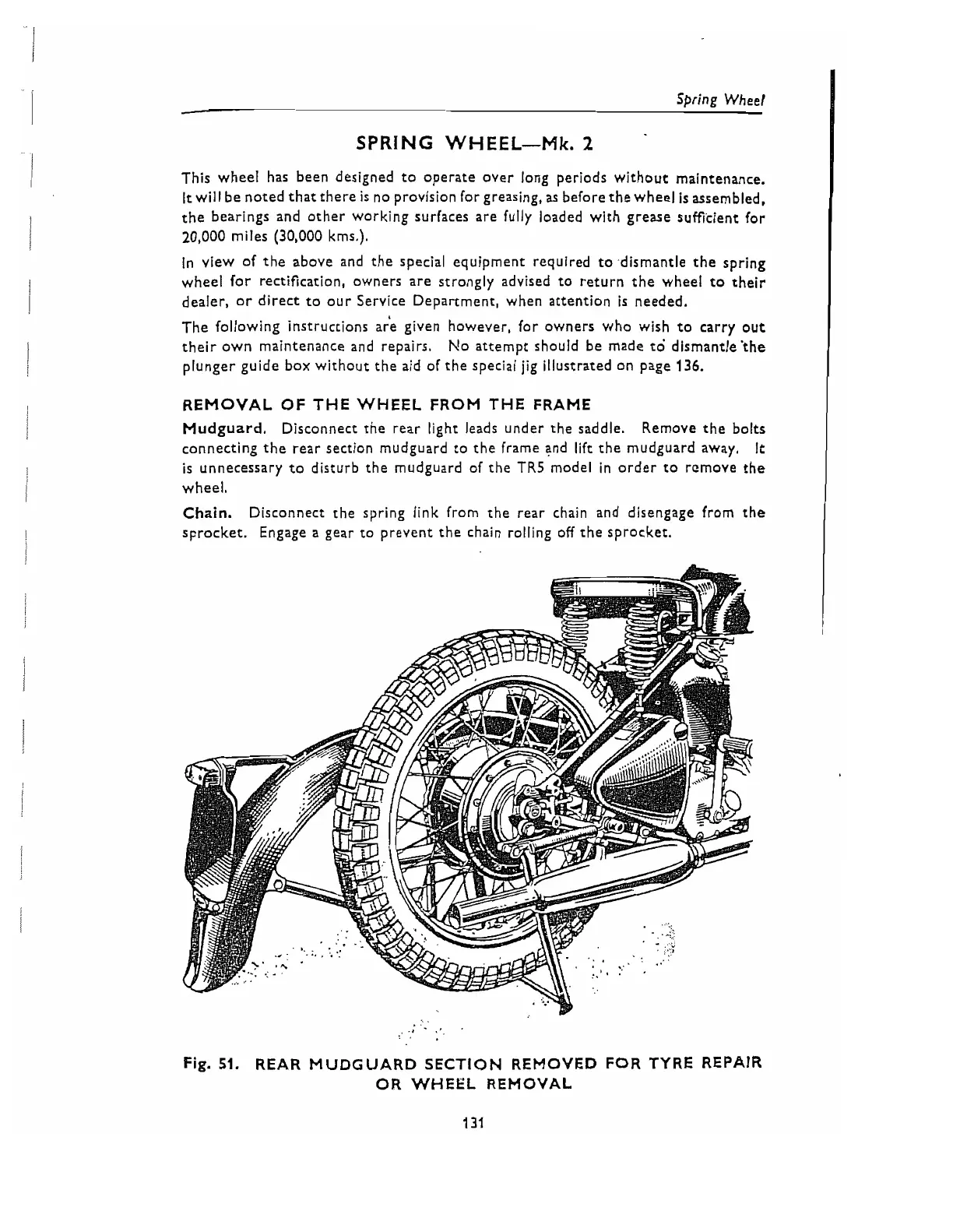

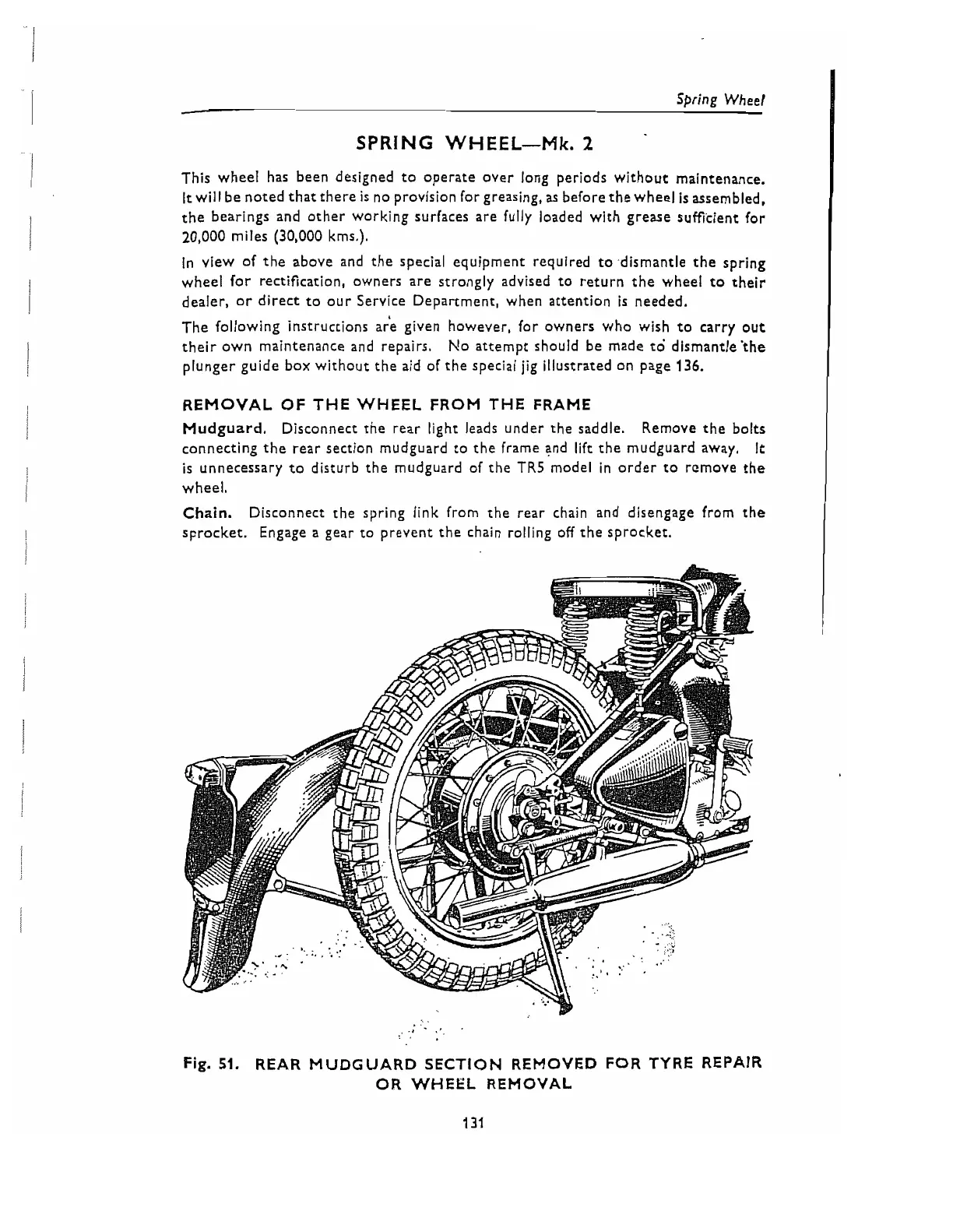

Fig.

51.

REAR MUDGUARD SECTION REMOVED FOR

TYRE

REPAIR

OR WHEEL REMOVAL

131

Loading...

Loading...