I

Distributor

I

2

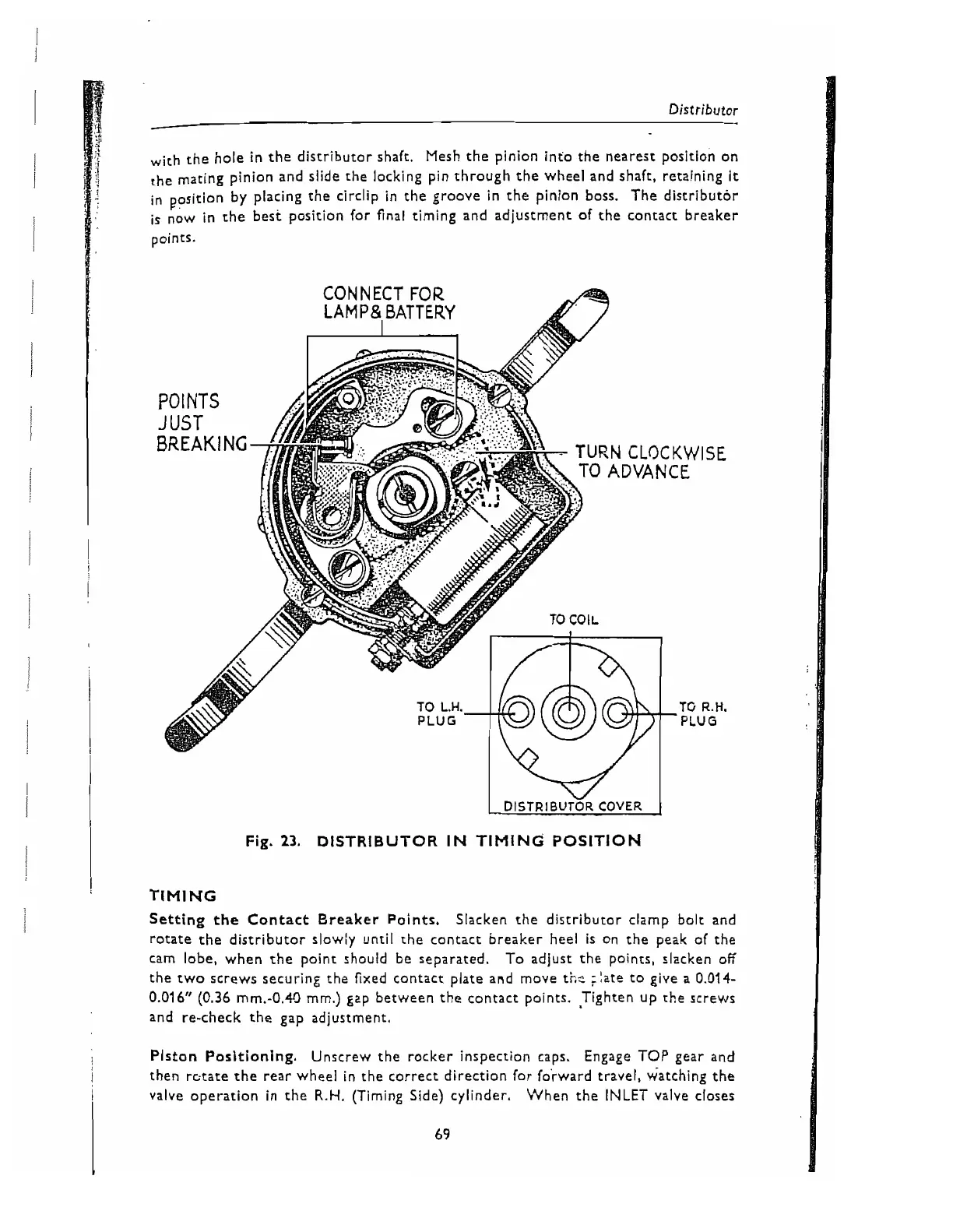

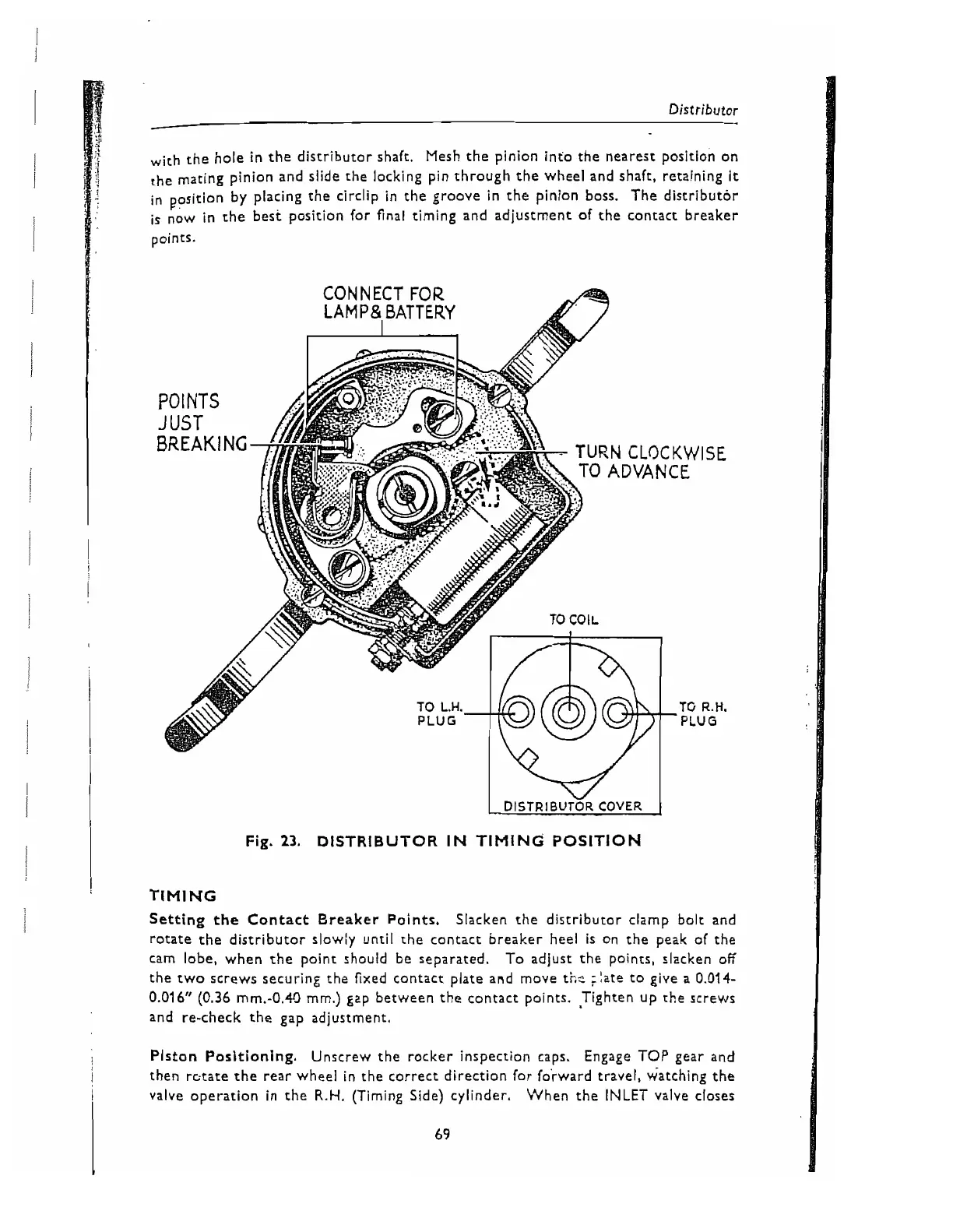

with the hole in the distributor shaft. Mesh the pinion into the nearest position on

I

11

mating pinion and slide the locking pin through the wheel and shaft, retaining

it

in

position by placing the circlip in the groove in the pinion boss. The distributor

i

is

now in the best position for final timing

and

adjustment of the contact breaker

I

points.

]

D~STRIBUT~R

COVER

I

Fig.

23.

DISTRIBUTOR

IN

TIMING POSITION

I

!

TIMING

i

Setting the Contact Breaker Points.

Slacken the distributor clamp bolt and

rotate the distributor slowly until the contact breaker heel is on the peak of the

cam lobe, when the point should be separated. To adjust the points, slacken off

the two screws securing the fixed contact plate and move ti.-, ;late to give a

0.014-

0.016"

(0.36 mm.-0.4 mm.) gap between the contact points. Tighten up the screws

and re-check the gap adjustment.

Piston

Positioning.

Unscrew the rocker inspection caps. Engage TOP gear and

I

then rctate the rear wheel in the correct direction for forward travel, watching the

i

valve operation in the

R.H.

(T~m~ng Side) cylinder.

When the INLET valve closes

Loading...

Loading...