Crankshaft and Connecting Rod Assembly.

The dismantling, bverhauf and

assembly of this unit

is

a job that

is

normally undertaken by the dealer,

or

at the works.

If the owner wishes to carry out the work, he must have

a

certain amount of

mechanical abil~ty and a good workshop.

Dismantling. Grip the bottom end of the flywheel in the vice and carefully mark

each rod so that they can be replaced in exactly the same position relative to the

cranks and the connecting rod cap to the rod itself. Unscrew the two nuts recurin,

each rod and remove the rods from the cranks. Replace the cap to the rods for

the time being.

Identify the cranks to the flywheel and then remove the six bolts

and nuts when the assembly can be parted.

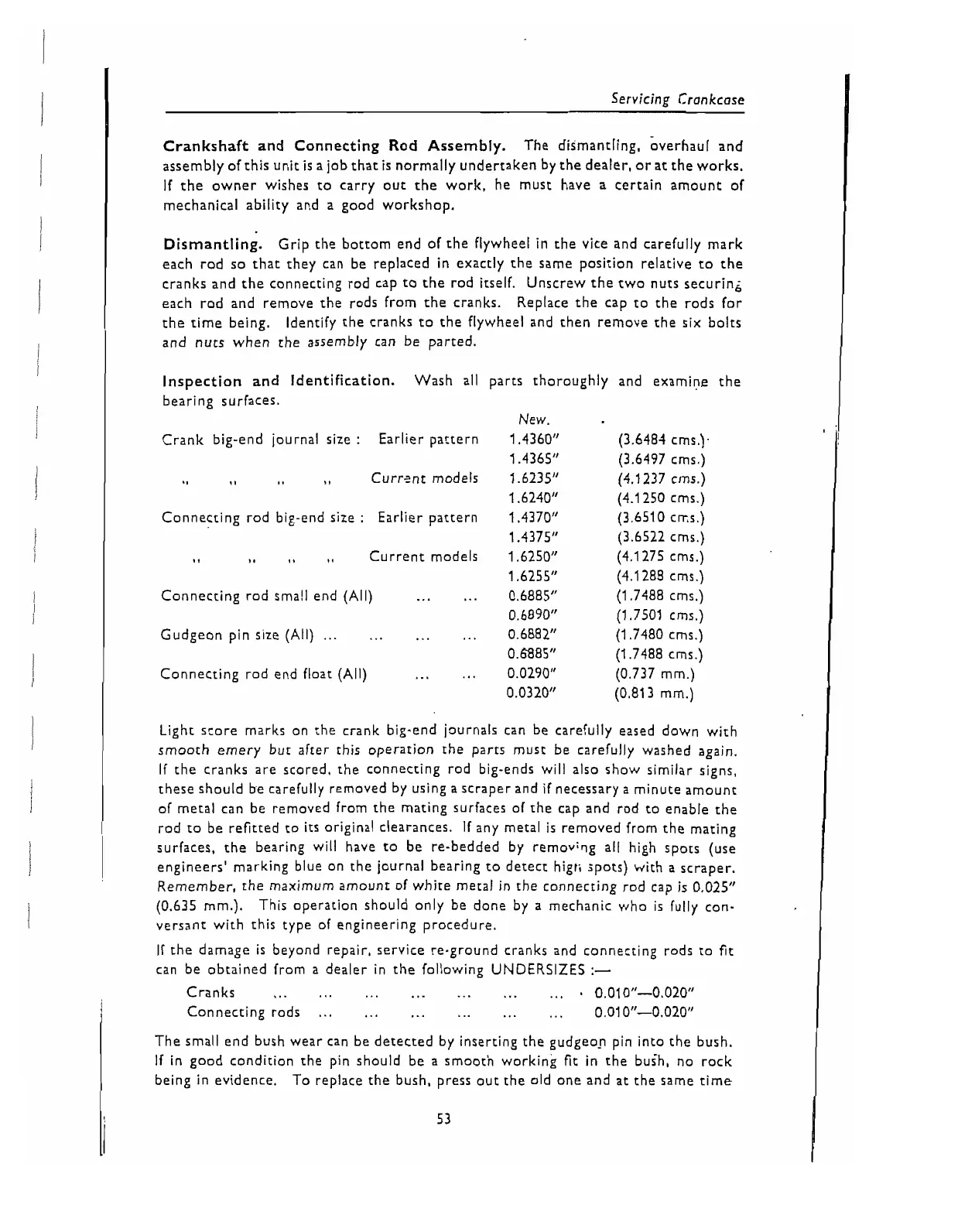

Inspection and Identification. Wash

all

parts thoroughly and examine the

bearing surfaces.

New.

Crank big-end journal size

:

Earlier pattern 1.4360" (3.6484 cms.)

1.4365" (3.6497 cms.)

Currsnt models 7.6235" (4.1237 cms.)

1.6240" (4.1 250 cms.)

Connecting rod big-end size

:

Earlier pattern 1.4370" (3.6510 cms.)

1.4375" (3.6522 cms.)

,,

,

Current models 1.6250" (4.1 275 cms.)

1.6255" (4.1 289 cms.)

Connecting rod sma!l end (All)

...

...

0.6885" (1.7488 cms.)

0.6890" (1.7501 cms.)

......

Gudgeon pin size (All)

...

...

0.6882" (1.7480 cms.)

0.6885" (1.7488 cms.)

Connecting rod end float (All)

...

...

0.0290" (0.737 mm.)

0.0320" (0.81

3

rnm.)

Light score marks on the crank big-end journals can be carefully eased down with

smooth emery but after this operation the parts must be carefully washed again.

If the cranks are scored, rhe connecting rod big-ends will also show similar signs,

these should be carefully removed by using

a

scraper and if necessary

a

minute amount

of metal can be removed from the mating surfaces of the cap and rod to enable the

rod

to

be refitted to

its

original clearances. If any metal

is

removed from the mating

surfaces, the bearing will have to be re-bedded by remov'qg

all

high spots (use

engineers' marking blue on the journal bearing to detect higri ipots) with a scraper.

Remember, the maximum amount of white metal in the connecting rod cap

is

0.025"

(0.635 mrn.). This operation should only be done by a mechanic who

is

fully con-

versant with this type of engineering procedure.

If the damage

is

beyond repair, service re.ground cranks and connecting rods to

fit

can be obtained from

a

dealer in the following UNDERSIZES

:-

Cranks

...

.,.

...

...

...

...

....

0.010"-0.020''

Connecting rods

...

...

...

... ...

...

0.01 0"-0.020''

The small end bush wear can be detected by inserting the gudgeon pin into the bush.

If in good condition the pin should be

a

smooth working

fit

in the buih, no rock

being in evidence. To replace the bush, press out the old one and

at

the same time

Loading...

Loading...