I

I I

Removing the Shock Absorber Rubbers. Engage the clutch locking tool (See

Fig.

33)

in the clutch housing and clutch centre. Slide the driveshaft adaptor, Part

I

No.

Z90

(Fig.

32)

onto the engine mainshaft, engaging the "dogged' end into the

I

1

exposed sprocket splines.

On the

6T

model the mainshaft nut must be replaced to

I

keep the adaptor in position for the next operation. Flace a suitable spanner onto the

adaptor hexagon so that the mainshaft can be rotated anti-clockwise to compress

1

the other rubbers.

Ease

the rebound rubbe- out and then relea;e the pressure on

I

1

the spanner when the drive rubbers can be removed.

Although this chapter deals with the dismantling of the clutch and shock absorber,

it

is

desirable at this point to explain the assembly of the shock absorber unit.

I

Replacing New Shock Absorber Rubbers. Position the four drive rubbers

I

(See Fig.

29)

and exert pressure on the spanner

to

replace the rebound rubbers.

I

Outer Retaining Pla:e. Ensure that the rubbers are correctly positioned and

i

fully in their housing and then replace the plate, securing with the four

2

B.A.

countersunk screws.

I

1

To

d~srnontle the remainder

of

the clutch proceed as follows:-

!

Clutch Push Rod. Remove from mainshaft.

1

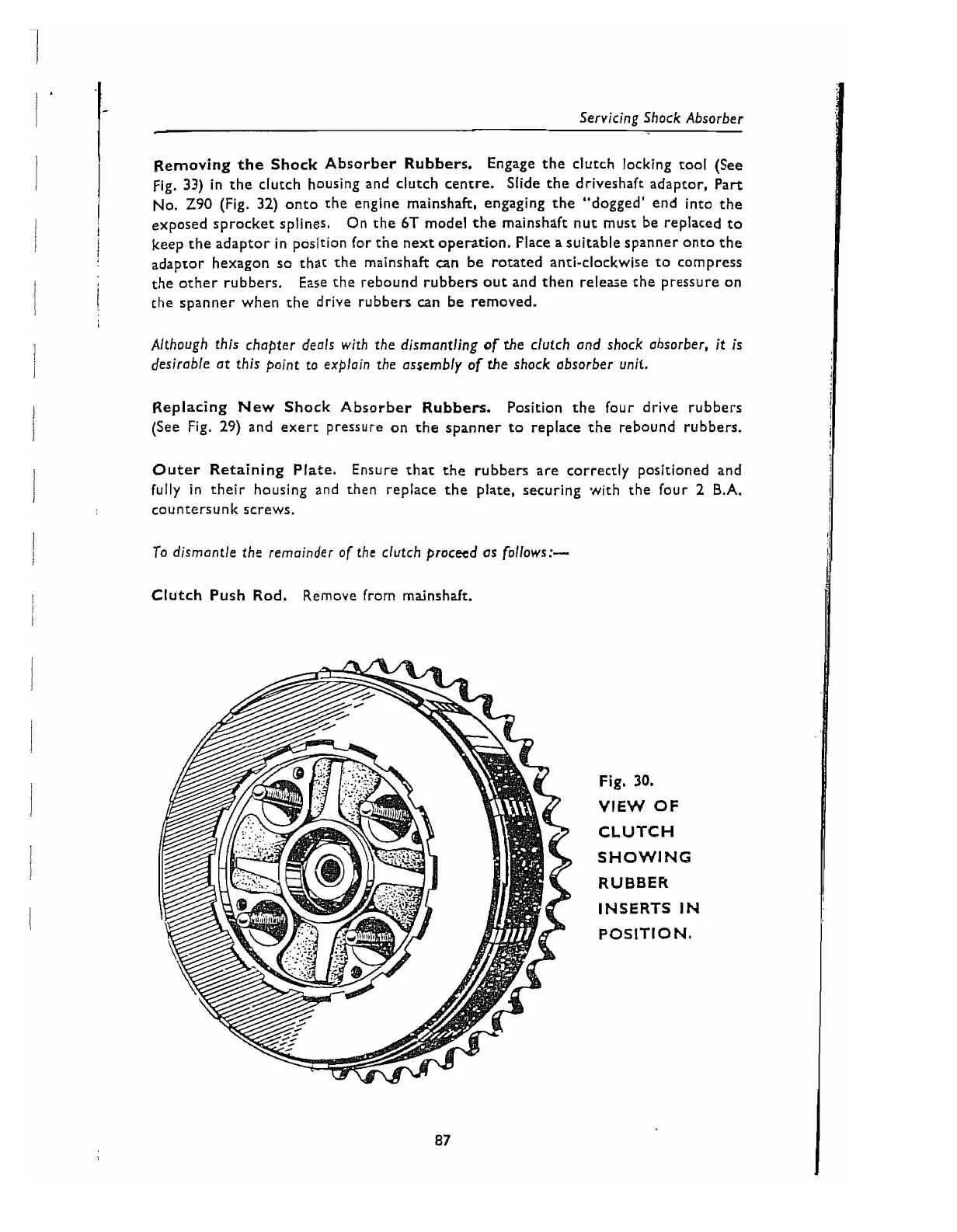

Fig.

30.

VIEW OF

CLUTCH

SHOWINC;

RUBBER

INSERTS

IN

POSITION.

Loading...

Loading...