Startup Procedure and Test Run

4

4.11 Fine Tuning during Test Runs (Adjust the Control Function)

YASKAWA SIEPC71061753C GA500 Technical Manual 153

■ Precaution When You Use IE3 Premium Efficiency Motors

IE3 motors have different motor characteristics from IE1 and other motors. Set the parameters as specified by the

motor characteristics. If you have a momentary power loss, and the drive detects oC [Overcurrent] or ov

[Overvoltage] during speed search after it restores power, set these parameters:

• b3-03 [Speed Search Deceleration Time] = default value × 2

• L2-03 [Minimum Baseblock Time] = default value × 2

• L2-04 [Powerloss V/f Recovery Ramp Time] = default value × 2

◆ Open Loop Vector Control Method

In Open Loop Vector Control, keep C4-01 [Torque Compensation Gain] at its default setting (1.00).

If you cannot get speed precision during regeneration in Open Loop Vector Control, set C3-04 = 1 [Slip

Compensation at Regen = Enabled Above 6 Hz].

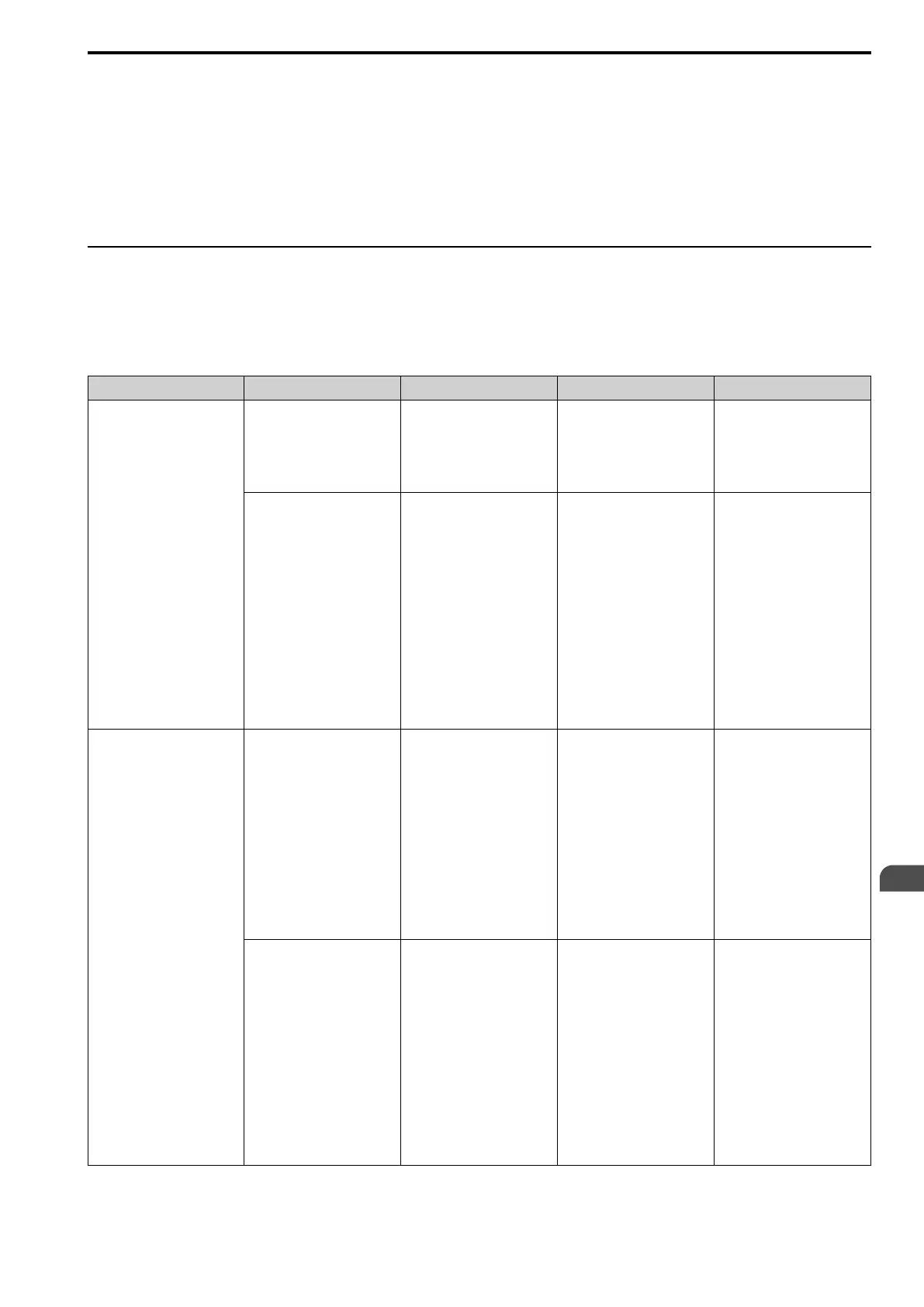

Table 4.19 Parameters for Fine Tuning the Drive (A1-02 = 2 [OLV])

Issue Parameter Number Possible Solutions Default Recommended Setting

• Unsatisfactory motor torque

and speed response

• Hunting or oscillation at mid-

range speeds (10 Hz to 40 Hz)

n2-01 [Automatic Freq Regulator

Gain]

• To increase the speed of torque

or speed response, decrease

the setting value in 0.05-unit

increments.

• If hunting or oscillation occur,

decrease the setting value in

0.05-unit increments.

1.00 0.50 to 2.00

n2-02 [Automatic Freq Regulator

Time 1]

• To increase the speed of torque

or speed response, decrease

the setting value in 10 ms

increments and examine the

response.

• If hunting or oscillation occur

or if the load inertia is too

much, increase the setting

value in 50 ms increments and

examine the response.

Note:

Make sure that this parameter

setting is: n2-02 ≤ n2-03

[Automatic Freq Regulator

Time 2].

When you adjust n2-02, you

must also increase the C4-02

[Torque Compensation Delay

Time] value by the same ratio.

50 ms 50 ms to 2000 ms

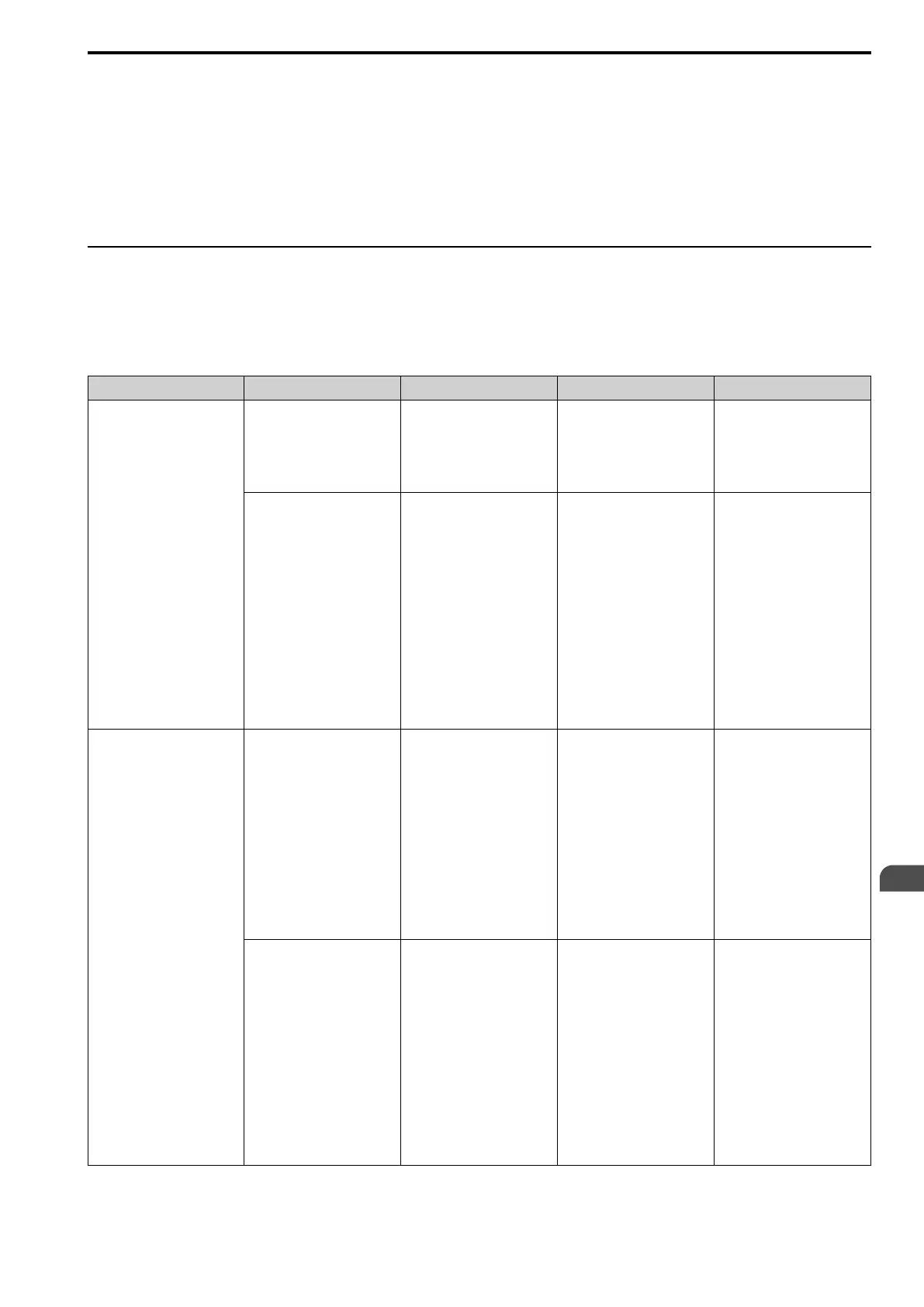

ov [Overvoltage] occurs when the

drive stops accelerating, starts to

decelerate, or when there are

large changes in the load.

n2-03 [Automatic Freq Regulator

Time 2]

• If ov occurs, increase the

setting value in 50 ms

increments and examine the

response.

• If the response is not

sufficient, decrease the setting

value in 10 ms increments and

examine the response.

Note:

Make sure that this parameter

setting is: n2-02 [Automatic

Freq Regulator Time 1] ≤ n2-

03. When you adjust n2-03,

you must also increase the

C4-06 [Motor 2 Torque Comp

Delay Time] value by the

same ratio.

750 ms 750 ms to 2000 ms

C4-06 [Motor 2 Torque Comp

Delay Time]

• If ov occurs, increase the

setting value in 10 ms

increments and examine the

response.

• If the response is not

sufficient, decrease the setting

value in 2 ms increments and

examine the response.

Note:

Make sure that this parameter

setting is: C4-02 [Torque

Compensation Delay Time] ≤

C4-06.

When you adjust C4-06, you

must also increase the n2-03

[Automatic Freq Regulator

Time 2] value by the same

ratio.

150 ms 150 ms to 750 ms

Loading...

Loading...