Parameter Details

12

12.10 n: Special Adjustment

YASKAWA SIEPC71061753C GA500 Technical Manual 739

Note:

• Set n2-02 ≤ n2-03 [Automatic Freq Regulator Time 2]. If n2-02 > n2-03, the drive will detect oPE08 [Parameter Selection Error].

• When you change the value in n2-02, also change the value in C4-02 [Torque Compensation Delay Time] by the same ratio.

■ n2-03: Automatic Freq Regulator Time 2

No.

(Hex.)

Name Description

Default

(Range)

n2-03

(0586)

Automatic Freq Regulator

Time 2

Sets the time constant that sets the speed difference of the AFR function. Use this parameter for

speed searches or regeneration. Usually it is not necessary to change this setting.

750 ms

(0 - 2000 ms)

Adjust this parameter in these conditions:

• If the drive detects ov [Overvoltage] when acceleration stops under high-inertia loads, increase the setting value

in 50 ms increments.

If the drive detects ov when the load changes suddenly, increase the setting value in 50 ms increments.

• To increase the responsiveness of torque and speed, decrease the setting value in 10 ms increments and examine

the response.

Note:

• Set n2-02 ≤ n2-03 [Automatic Freq Regulator Time 2]. If n2-02 > n2-03, the drive will detect oPE08 [Parameter Selection Error].

• When you change the value in n2-03, also change the value in C4-06 [Motor 2 Torque Comp Delay Time] by the same ratio.

◆ n3: High Slip Braking (HSB) and Overexcitation Braking

n3 parameters configure High Slip Braking and Overexcitation Deceleration.

■ High Slip Braking (HSB)

High slip braking quickly decelerates motors without braking resistors.

This lets you stop a motor more quickly than with the ramp to stop processes. This function is best for

applications that do not frequently stop the motor, for example the fast stop function for high-inertia loads.

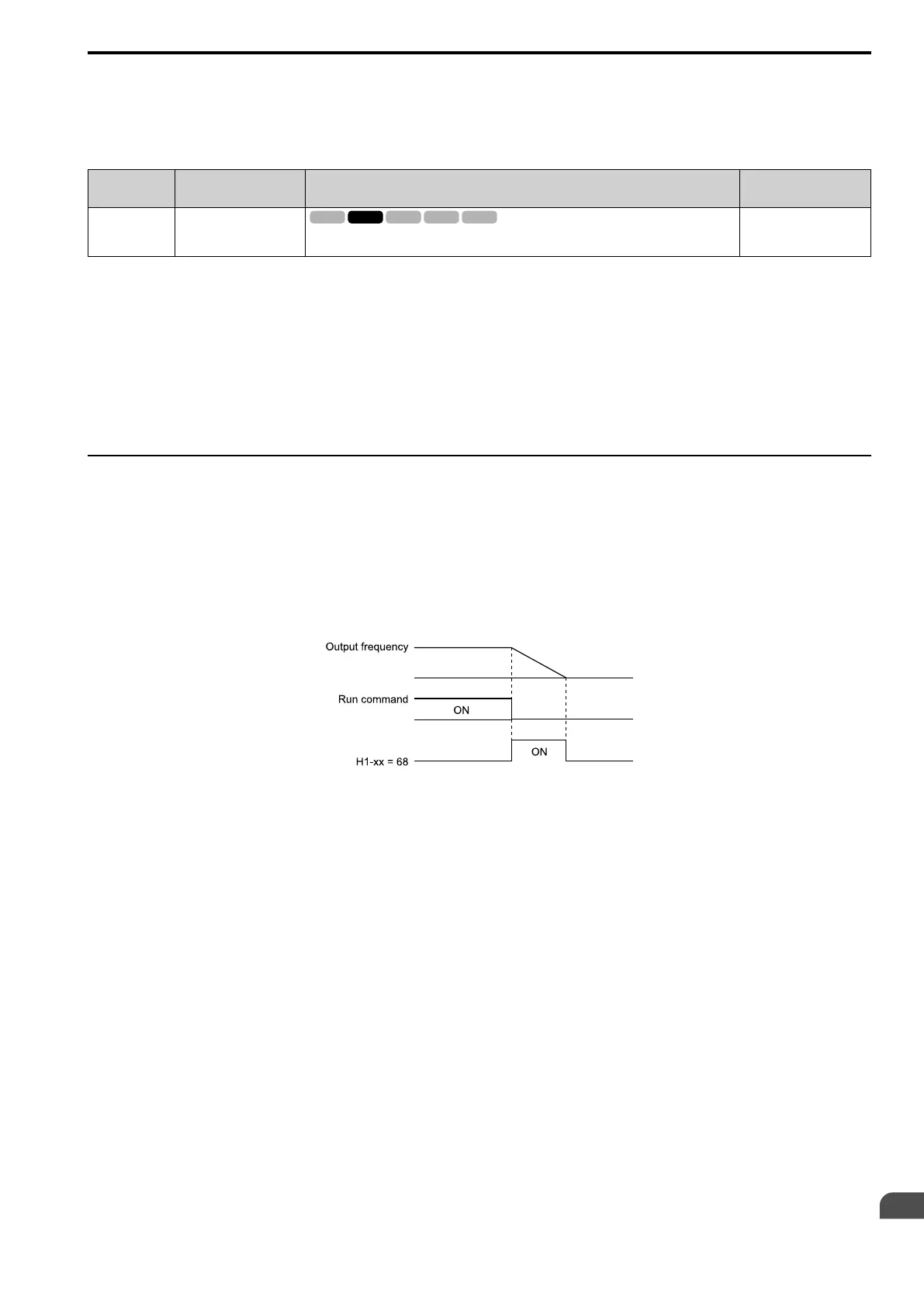

Braking starts when the MFDI for High Slip Braking (HSB) Activate [H1-xx = 68] activates.

Figure 12.132 High Slip Braking Time Chart

An induction motor is necessary to use high slip braking. Set A1-02 = 0 [Control Method Selection = V/f Control]

to enable high slip braking:

Principles of Operation

HSB increases motor slip by significantly decreasing the frequency supplied to the motor at the same time that

deceleration starts. A large quantity of current flows through the motor to increase the motor loss, and the motor

decelerates while the motor windings consume the regenerative energy.

The drive keeps the motor current at a constant level during deceleration to prevent overvoltage and do automatic

braking and it also keeps a slip level that causes the maximum quantity of deceleration torque.

High Slip Braking Precautions

• Do not use the high slip braking function in these applications:

– Frequent deceleration

– Deceleration time differences

– Continuous regenerative loads

– It is necessary to accelerate again during deceleration

• Motor loss increases during high slip braking. Use this function when the duty time factor is 5% ED or less and

the braking time is 90 seconds or less. The load inertia and motor characteristics have an effect on the braking

time.

Loading...

Loading...