Recommended annual actions by the user

PDC circuit capacitors reforming for spare modules and spare capacitors

Inspections by user

ITightness of terminals

IDustiness, corrosion and temperature

PHeat sink cleaning

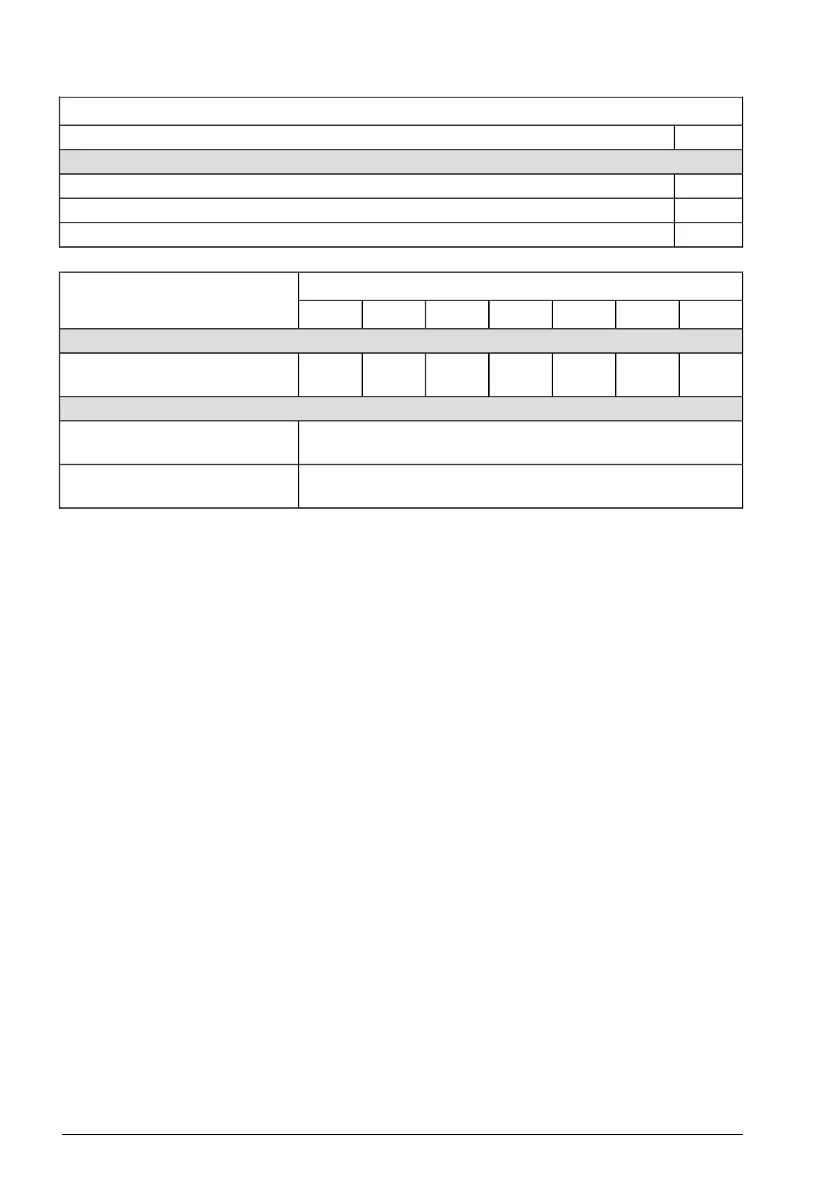

Years from start-upMaintenance task/object

21181512963

Cooling fans

(R)R(R)R(R)R(R)

Main cooling fan

1)

(R)(R)(R)

Functional safety

ISafety function test

See the maintenance information of the safety function.

20 yearsSafety component expiry (Mission

time T

M

)

1)

(R) = replacement of component in demanding operating conditions, ie. if surrounding air temperature in

continuous operation is over 40 °C (104 °F) or there is a cyclic heavy load.

Note:

• Maintenance and component replacement intervals are based on the assumption

that the equipment is operated within the specified ratings and ambient conditions.

ABB recommends annual drive inspections to ensure the highest reliability and

optimum performance.

• Long term operation near the specified maximum ratings or ambient conditions may

require shorter maintenance intervals for certain components. Consult your local

ABB Service representative for additional maintenance recommendations.

Functional safety components

The mission time of functional safety components is 20 years which equals the time

during which failure rates of electronic components remain constant. This applies to the

components of the standard Safe torque off circuit as well as any modules, relays and,

typically, any other components that are part of functional safety circuits.

The expiry of mission time terminates the certification and SIL/PL classification of the

safety function. The following options exist:

• Renewal of the whole drive and all optional functional safety module(s) and

components.

120 Maintenance

Loading...

Loading...