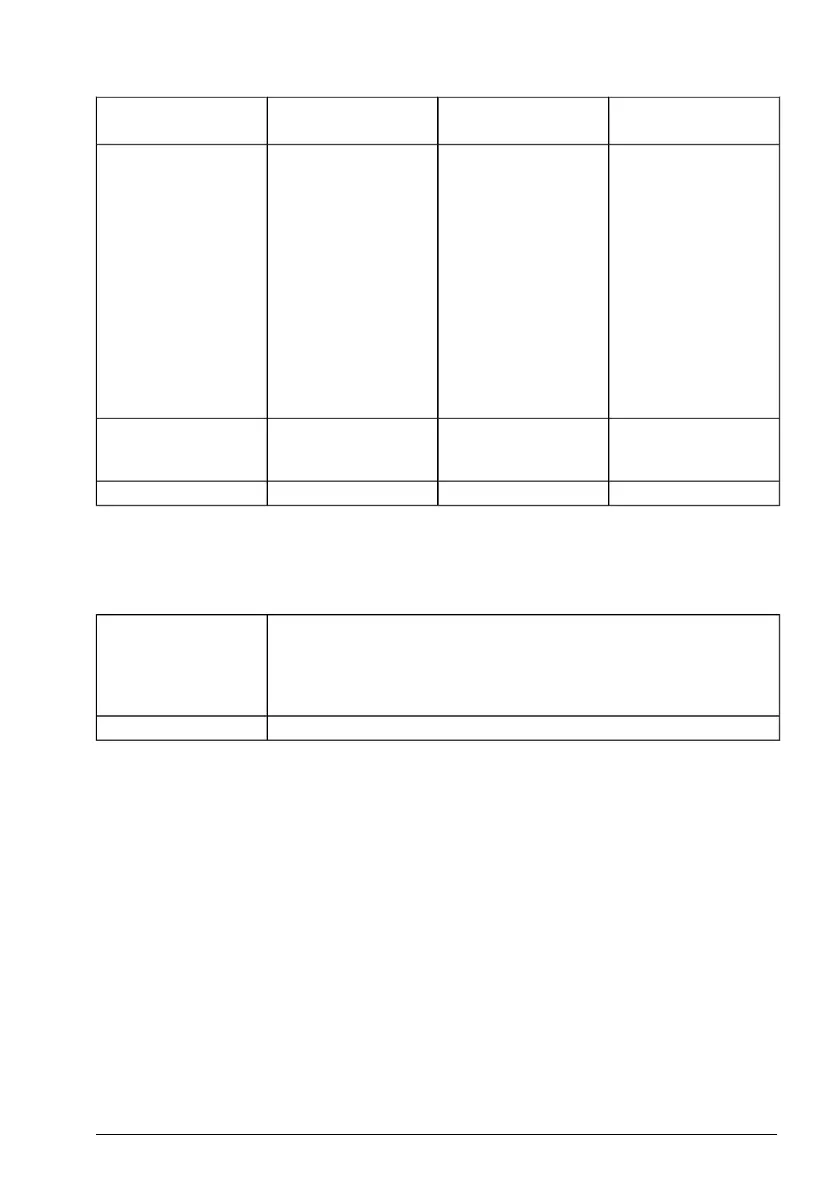

Transportation in the

protective package

Storage in the protect-

ive package

Operation installed

for stationary use

Requirement

--frequency

10 … 150 Hz;

Sinusoidal vibration

(IEC 60068-2-6, Test

Fc 2007-12) amplitude ±0.075 mm

(0.003 in),

10 … 57,56 Hz;

constant peak accelera-

tion 10 m/s2 (33 ft/s2),

57,56 … 150 Hz;

sweep: 1 oct/min;

10 sweep cycles in

each axis with STO

active;

uncertainty ±5.0%;

normal mounting

According to ISTA 1A.According to ISTA 1A.Not permittedShock/(IEC 60068-2-

27, ISTA 1A) Max. 100 m/s

2

(330 ft/s

2

), 11 ms.

Max. 100 m/s

2

(330 ft/s

2

), 11 ms.

76 cm (30 in)76 cm (30 in)-Free fall

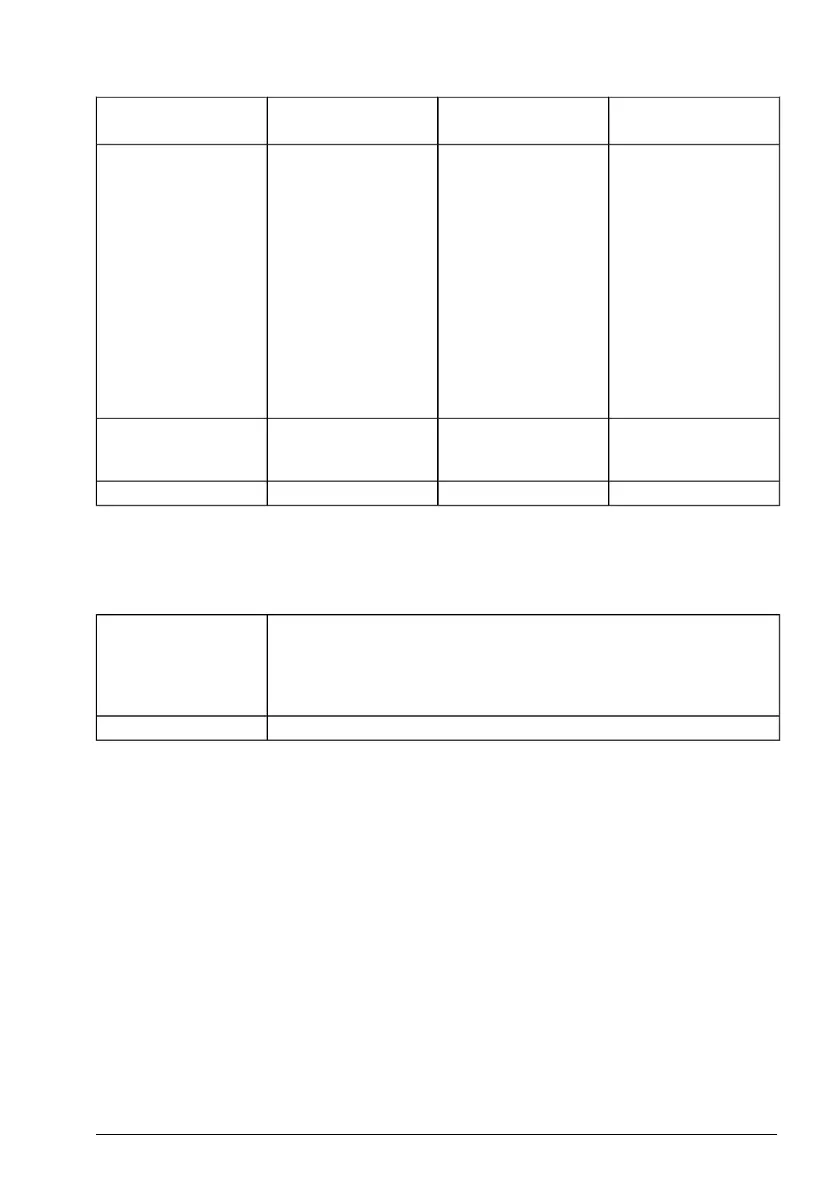

Materials

■ Materials

Hot-dip zinc coated steel sheet 1.5 mm (0.06 in). Extruded aluminum

AlSi.

PC/ABS 2 mm (0.08 in), PC+10%GF 2.5 … 3 mm (0.10 … 0.12 in) and

PA66+25%GF 1.5 mm (0.06 in), all in color NCS 1502-Y (RAL 9002 /

PMS 420 C)

Drive enclosure

Corrugated cardboardPackage

■ Disposal

The main parts of the drive can be recycled to preserve natural resources and energy.

Product parts and materials should be dismantled and separated.

Generally all metals, such as steel, aluminum, copper and its alloys, and precious metals

can be recycled as material. Plastics, rubber, cardboard and other packaging material

can be used in energy recovery. Printed circuit boards and large electrolytic capacitors

need selective treatment according to IEC 62635 guidelines. To aid recycling, plastic

parts are marked with an appropriate identification code.

Contact your local ABB distributor for further information on environmental aspects and

recycling instructions for professional recyclers. End of life treatment must follow

international and local regulations.

Technical data 157

Loading...

Loading...