020263Y Sheath for driven pulley fitting

Recommended products

AGIP GREASE SM 2 Grease for the tone wheel

revolving ring

Soap-based lithium grease containing NLGI 2 Mo-

lybdenum disulphide; ISO-L-XBCHB2, DIN

KF2K-20

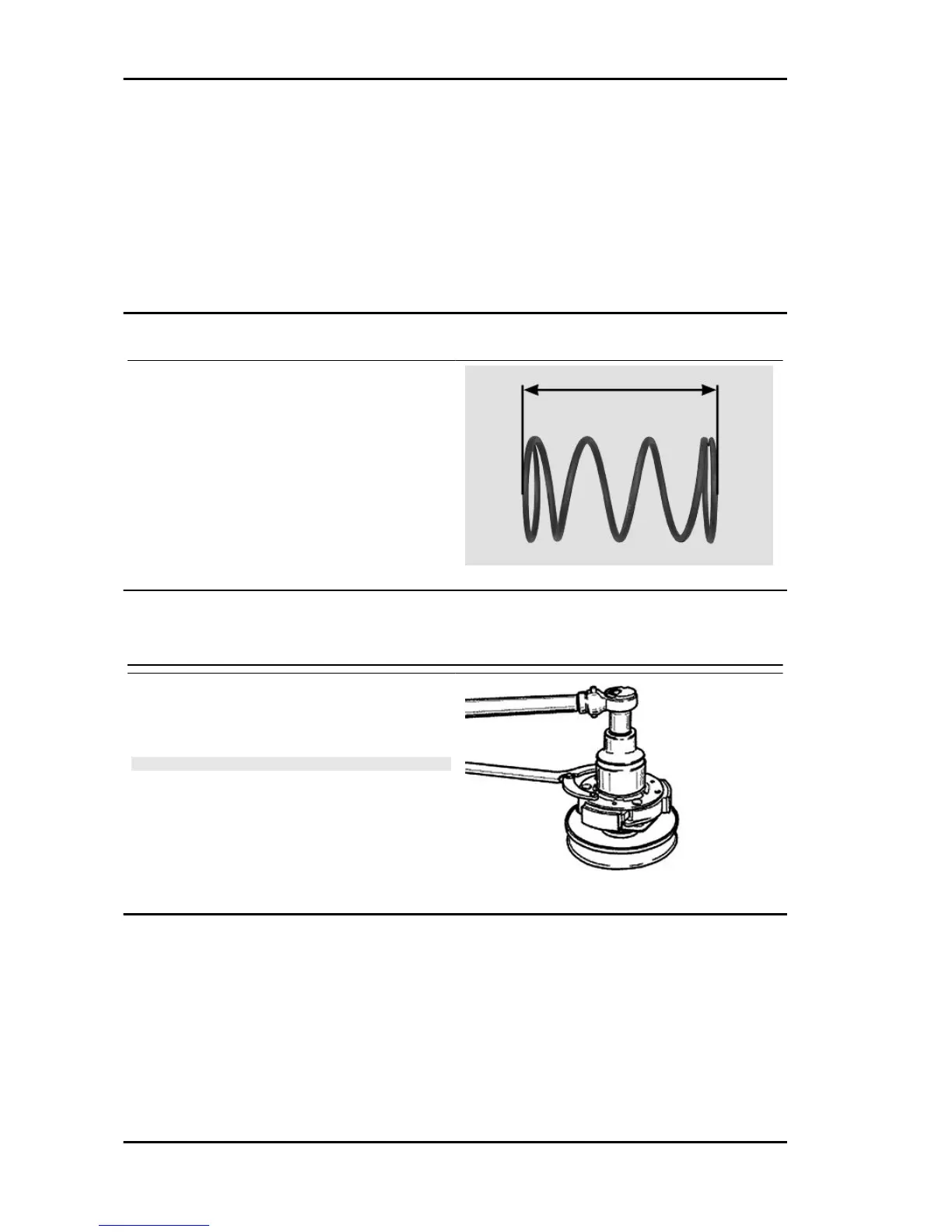

Inspecting the clutch spring

- Measure the unloaded length of the spring of the

movable driven half-pulley.

Characteristic

Standard length:

106 mm

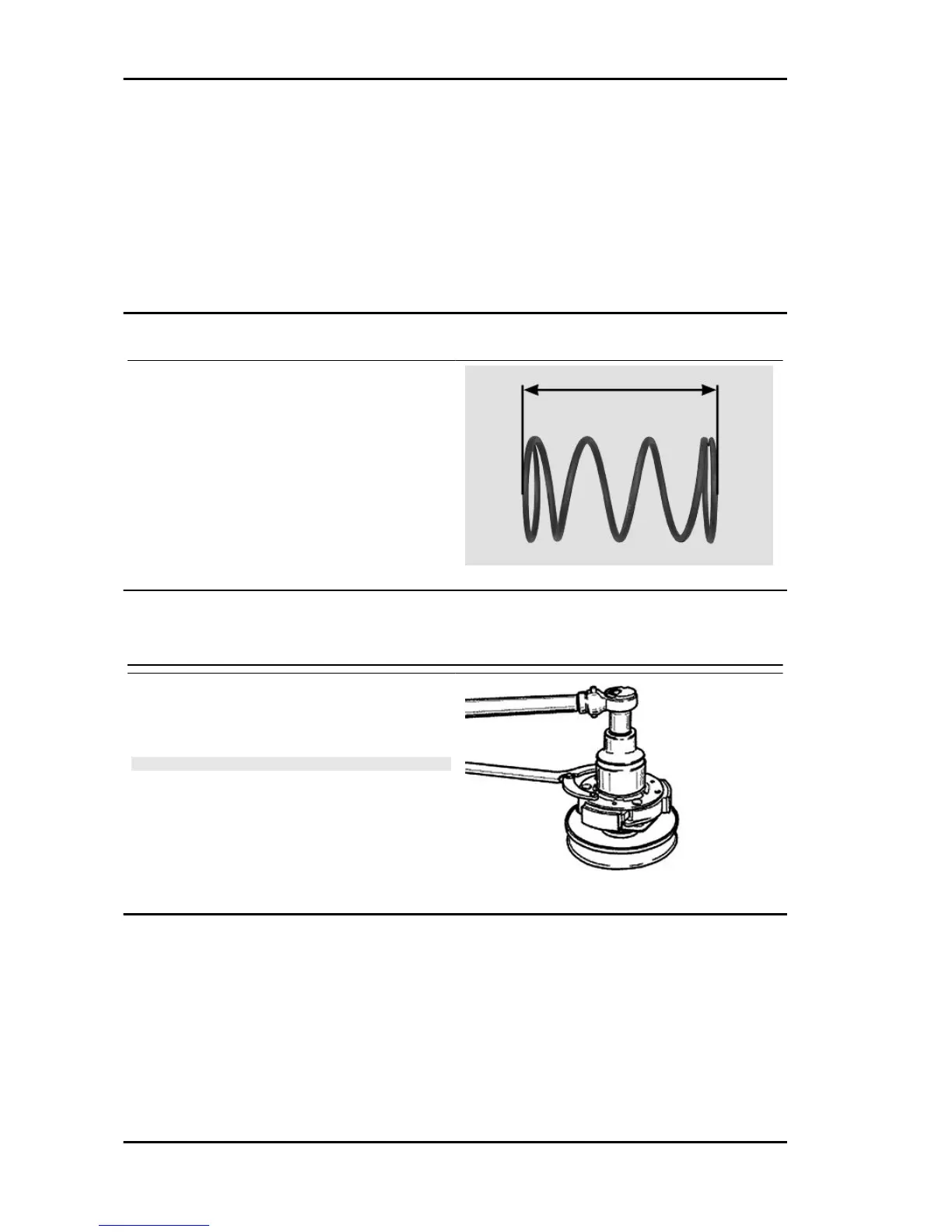

Refitting the clutch

Versione 125

- Refit the clutch assembly following the removal

operations but in reverse order, use the calliper

spanner and lock the nut to the prescribed torque.

CAUTION

USE A BOX-SPANNER WITH SMALL CHAMFER SO AS

NOT TO DAMAGE THE CLUTCH NUT. UPON FITTING THE

CLUTCH ASSEMBLY LOCK NUT, MAKE SURE THE AS-

SEMBLY IS WELL SECURED IN IT SEAT UNTIL SOME

SCREW THREADS HOLD IT IN PLACE.

Locking torques (N*m)

Locking torque 55 ÷ 60 Nm

Engine SPORTCITY ONE 125

ENG - 72

Loading...

Loading...