6

3

CYLINDER BLOCK INSPECTION AND REPAIR

2. Install camshaft bearing, Fig. 7.

a. Use camshaft bearing driver, Tool #19422.

NOTE: Notch on camshaft bearing must face out.

Be sure oil hole in bearing is aligned with

oil hole in cylinder block.

Fig. 7 – Installing Cam Bearing

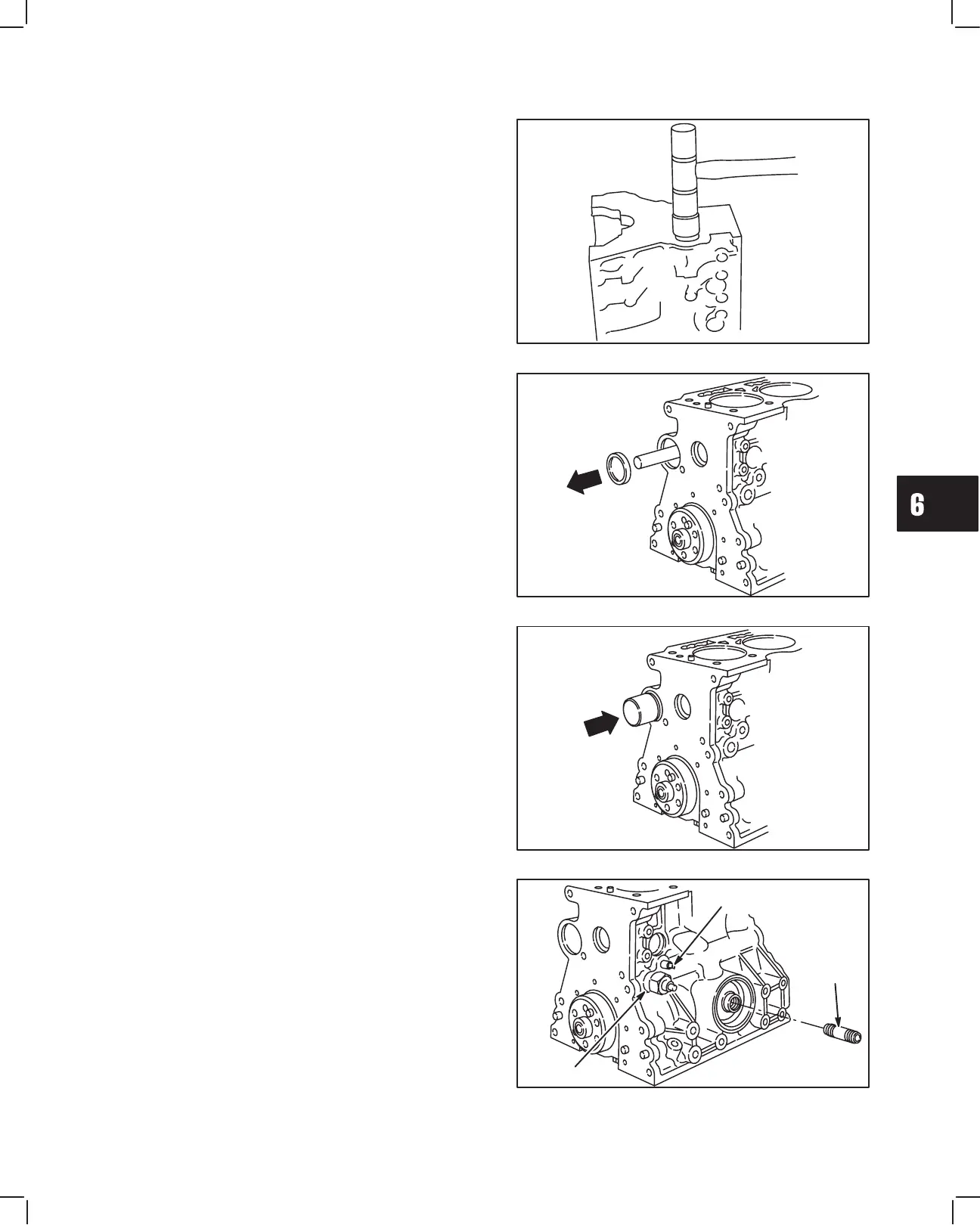

REPLACING CAMSHAFT PLUG

1. Remove rear camshaft plug, Fig. 8.

a. Use a wood dowel or brass rod to prevent

damage to camshaft bearing.

Fig. 8 – Removing Camshaft Plug

2. Install new camshaft plug using camshaft bearing

driver, Tool #19422.

a. Install camshaft plug flush with cylinder block,

Fig. 9.

Fig. 9 – Installing Camshaft Plug

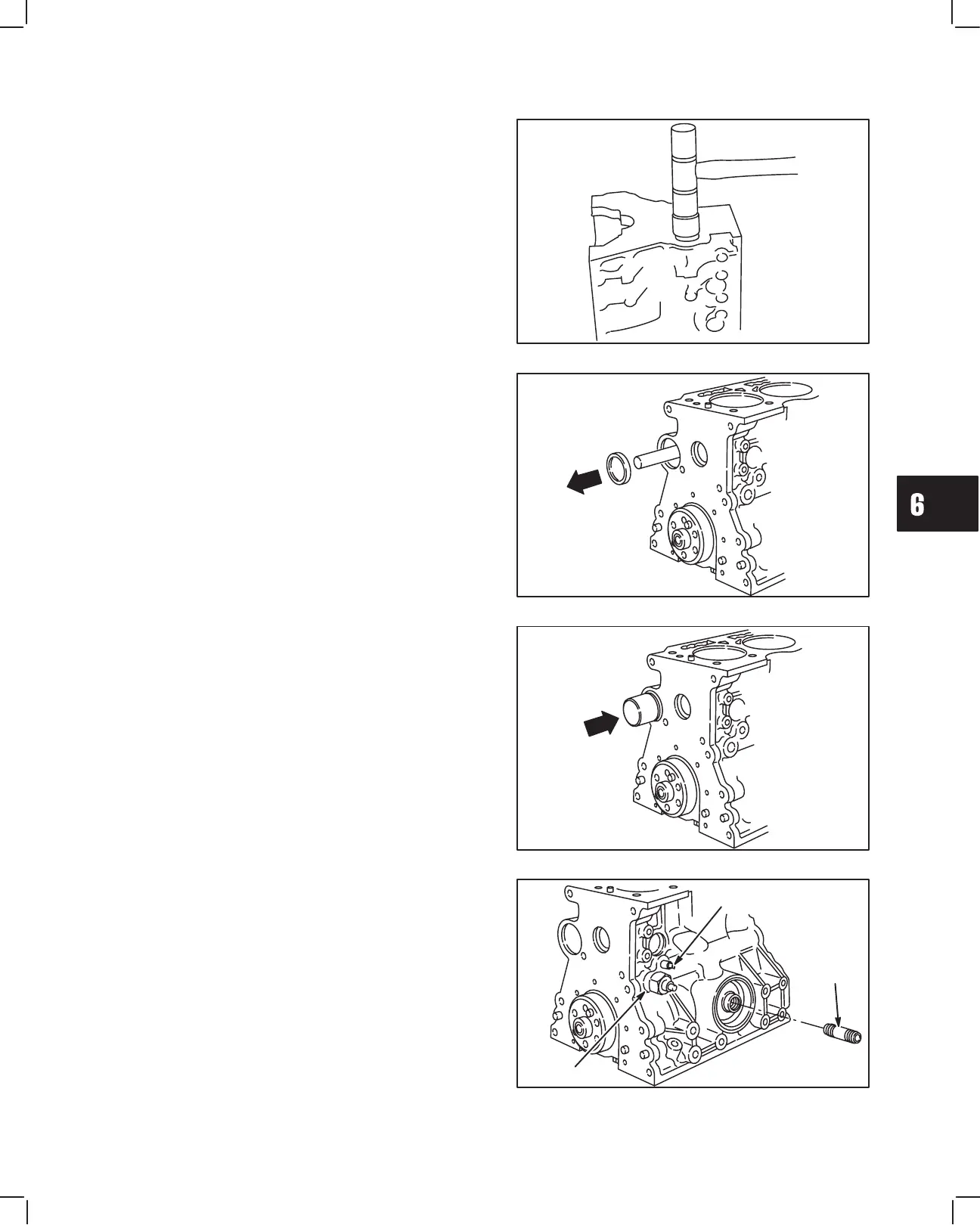

If cylinder block is being resized, the following

parts should be removed so that cylinder block

may be thoroughly cleaned.

1. Remove oil pressure switch, water gallery plug

and oil filter adapter, Fig. 10.

Fig. 10 – Removing Oil Pressure Switch

ADAPTER

PLUG

SWITCH

Loading...

Loading...