11

13

CHARGING SYSTEMS

INSTALL BALL BEARING

1. Lightly lubricate bearing O.D. with engine oil.

2. Press in new bearing using bearing driver #19226,

Fig. 30.

3. Install retainer and four screws.

Fig. 30 – Install Ball Bearing

19226 DRIVER

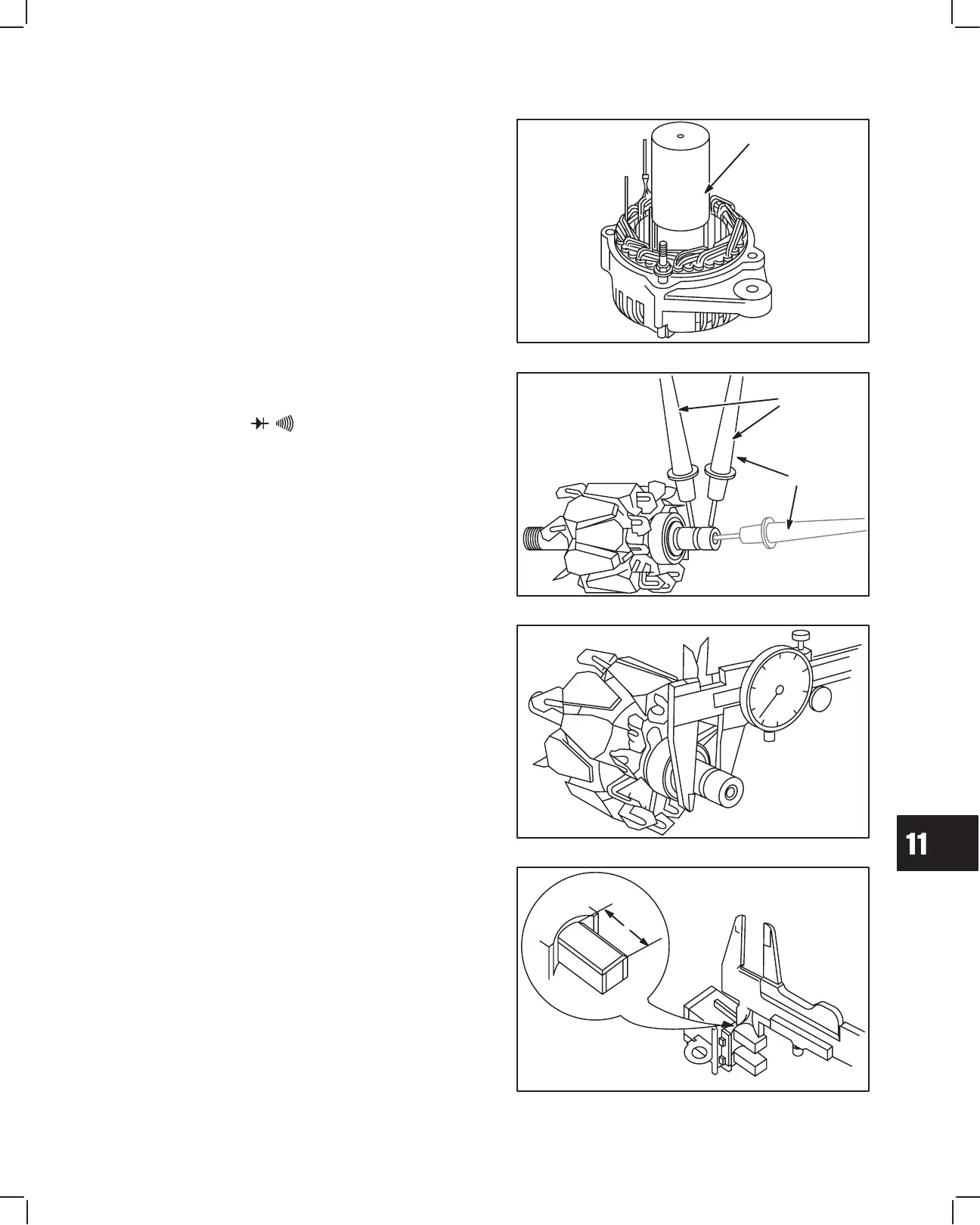

CHECKING ROTOR

The following test will be made with the meter in the

“Diode Test Position” .

1. Use digital multimeter and check for continuity

between slip rings as shown, Fig. 31.

a. Meter should make continuous tone

(continuity).

b. If meter displays “OL”, (no continuity) replace

rotor.

2. Check for continuity between slip ring and rotor

shaft.

a. Meter should display “OL”, (no continuity).

Fig. 31 – Check Rotor

1

2

3. Measure slip ring diameter, Fig. 32.

STD: 14.4 mm (.567”)

Reject: 14.0 mm (.551”)

Slip rings may be cleaned with fine sandpaper (#300 –

500 grit).

Fig. 32 – Check Slip Ring

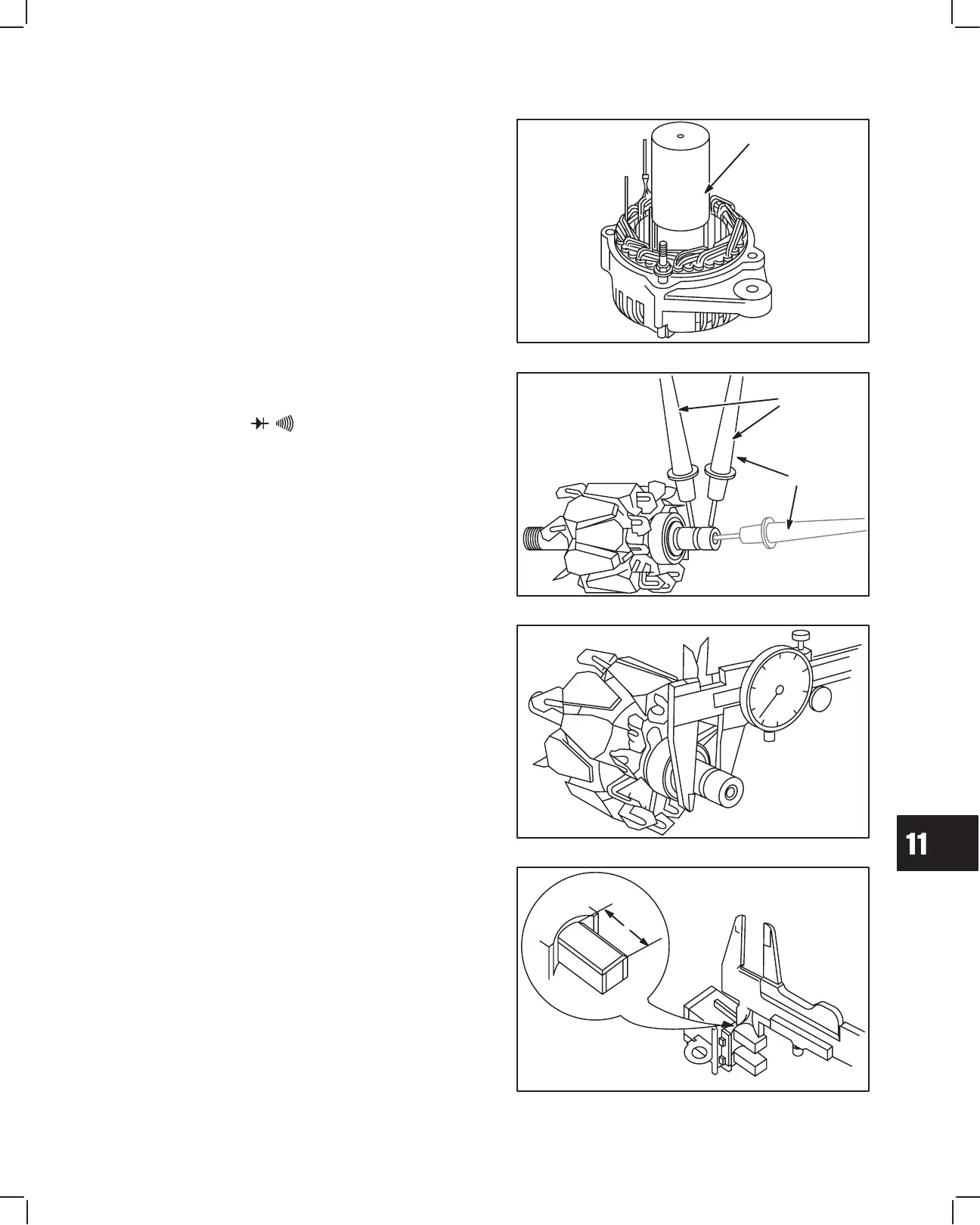

CHECK BRUSHES

Measure length of brushes protruding from brush

holder, Fig. 33.

STD: 10.5 mm (.413”)

Reject: 8.0 mm (.315”)

Fig. 33 – Check Brushes

Loading...

Loading...