7

2

CRANKSHAFT, CAMSHAFT AND BEARINGS

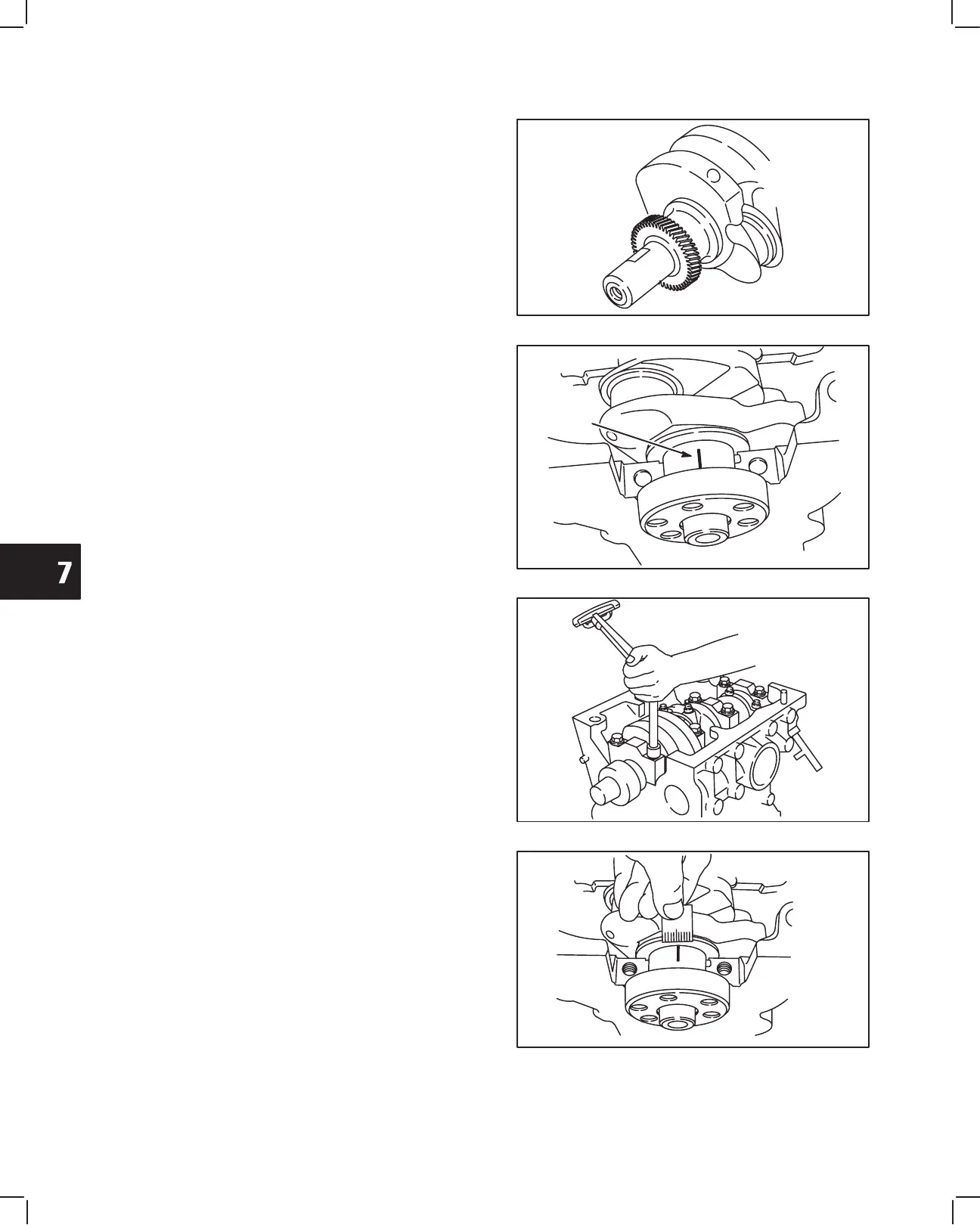

3. Check crankshaft timing gear teeth for damaged

teeth, Fig. 3.

NOTE: See Section 3 for procedure to check

crankshaft timing gear for wear.

If crankshaft timing gear teeth are damaged or worn,

the crankshaft must be replaced.

Fig. 3 – Checking Timing Gear

CHECKING MAIN BEARING CLEARANCES

If main bearings show signs of flaking or scoring,

bearings must be replaced.

Main bearing saddles in cylinder block, main bearing

caps, main bearings and crankshaft journals must be

clean and free of oil.

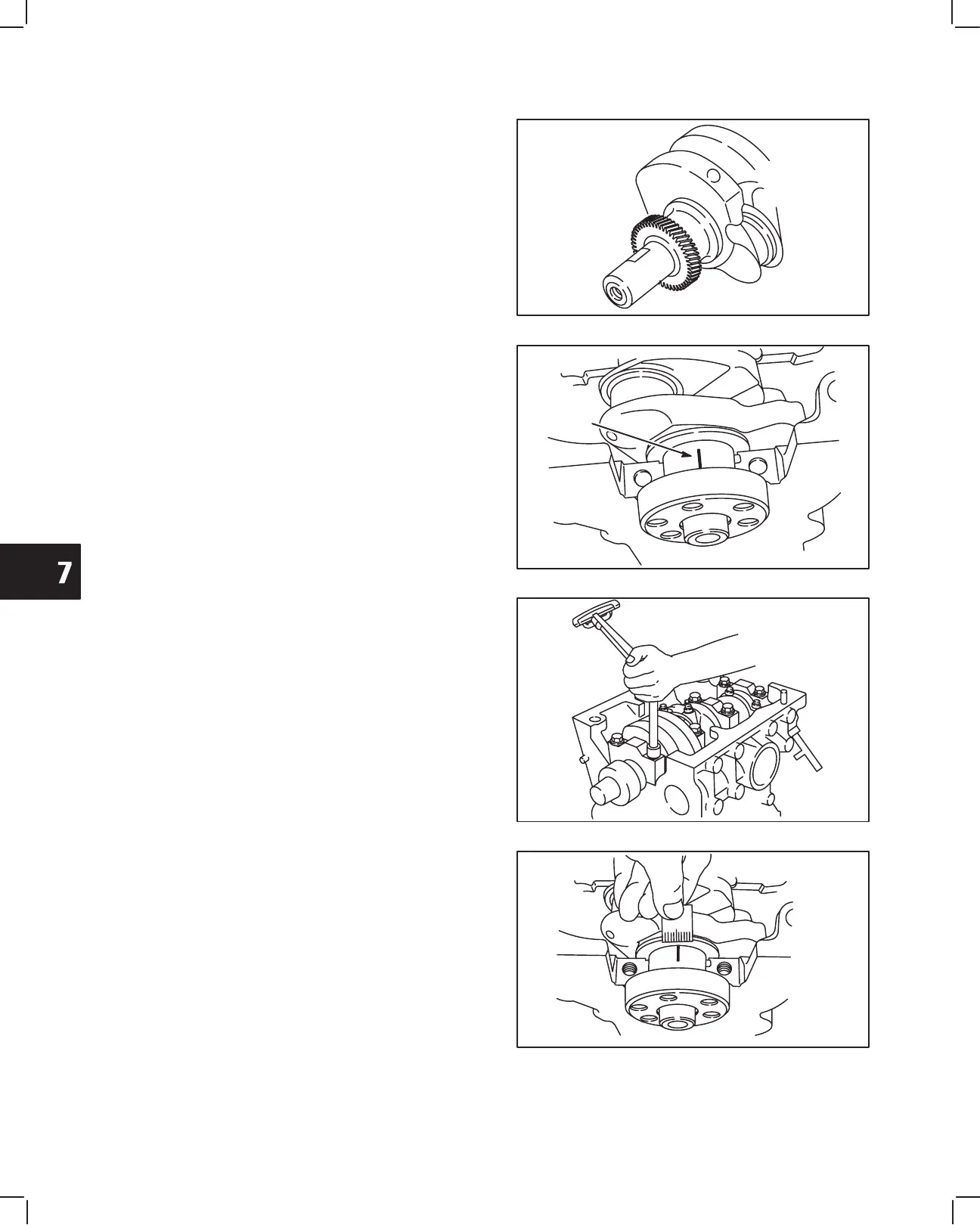

1. With upper main bearings installed, install crank-

shaft.

a. Lay a strip of plastigage lengthwise on journal,

Fig. 4.

Do not lay plastigage across oil hole in crankshaft

journal.

Fig. 4 – Install Plastigage

PLASTIGAGE

2. Assemble main bearing cap with bearing and

torque to 58.3 Nm (43 ft. lbs.), Fig. 5.

DO NOT ALLOW CRANKSHAFT TO ROTATE.

Fig. 5 – Torque Bearing Cap

3. Remove the bearing cap. Measure the plastigage

at its widest point, Fig. 6. If the clearance is not

within specification, replace the bearings.

Crankshaft Main Bearing Clearance:

STD: 0.020-0.044 mm (0.0008-0.0017”)

Reject: 0.07 mm (0.0028”)

Repeat procedure for each main bearing.

Fig. 6 – Measure Clearance

Loading...

Loading...