9

3

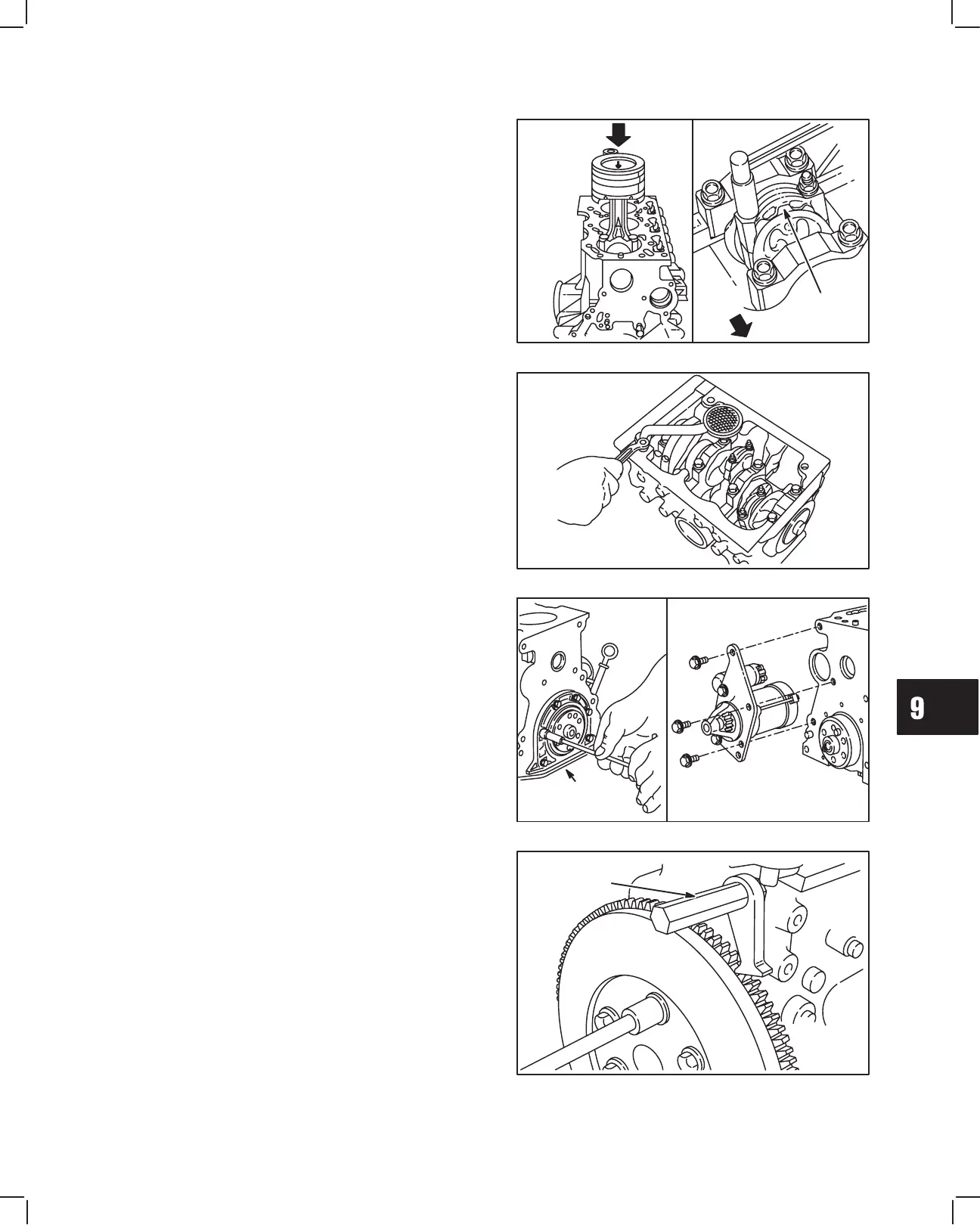

CYLINDER BLOCK ASSEMBLY

Rotate crankshaft so that crankpin is at bottom of

stroke. Then, lubricate cylinder walls, piston and rings,

bearings and crankpins.

2. Using ring compressor, Tool #19070, install piston

and connecting rod assemblies with arrow on

piston facing front, Fig. 6.

a. Install connecting rod cap with ID mark facing

front. Lubricate threads and torque nuts to

34.0 Nm (320 in. lbs.).

NOTE: After torquing rod cap, make sure crank-

shaft rotates freely before proceeding to

next cylinder.

Fig. 6 – Installing Piston And Connecting Rod

ID MARK

FRONT

GENERAL ASSEMBLY

1. Install gasket, oil pick-up tube and strainer, Fig. 7.

a. Torque screws to 8.0 Nm (70 in. lbs.).

Fig. 7 – Installing Oil Pick-Up

2. Install gasket and rear seal retainer, Fig. 8.

a. Torque screws to 6.0 Nm (50 in. lbs.).

3. Install starter motor.

a. Torque screws to 34.0 Nm (25 ft. lbs.).

Fig. 8 – Installing Rear Seal Retainer

REAR

SEAL

RETAINER

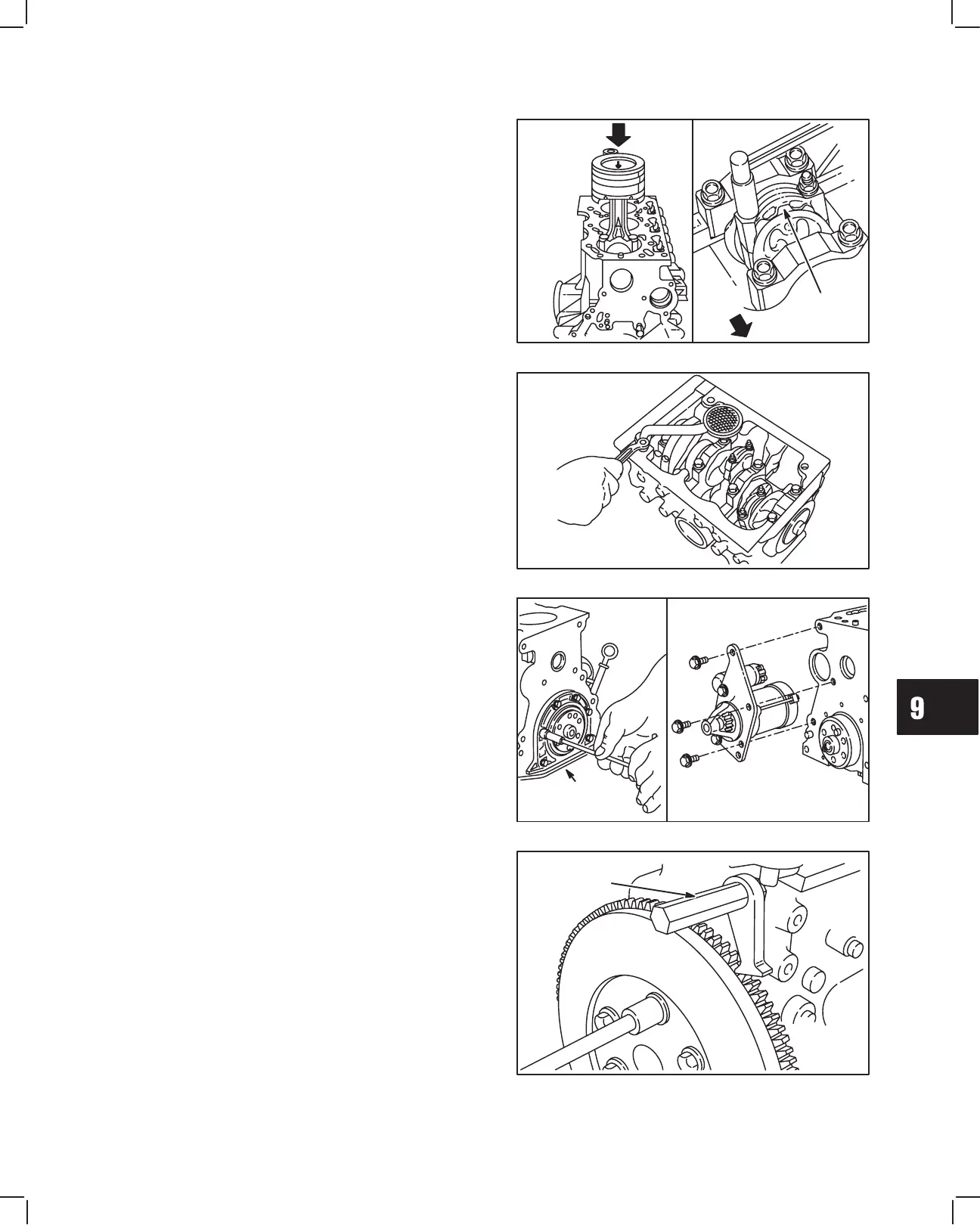

4. Install flywheel, Fig. 9.

a. Install flywheel holder, Tool #19418.

b. Apply Permatex No. 2 or similar sealant to

flywheel screws and torque to 47.0 Nm

(35 ft. lbs.).

Fig. 9 – Installing Flywheel

FLYWHEEL

HOLDER

Loading...

Loading...