10

7

INJECTORS

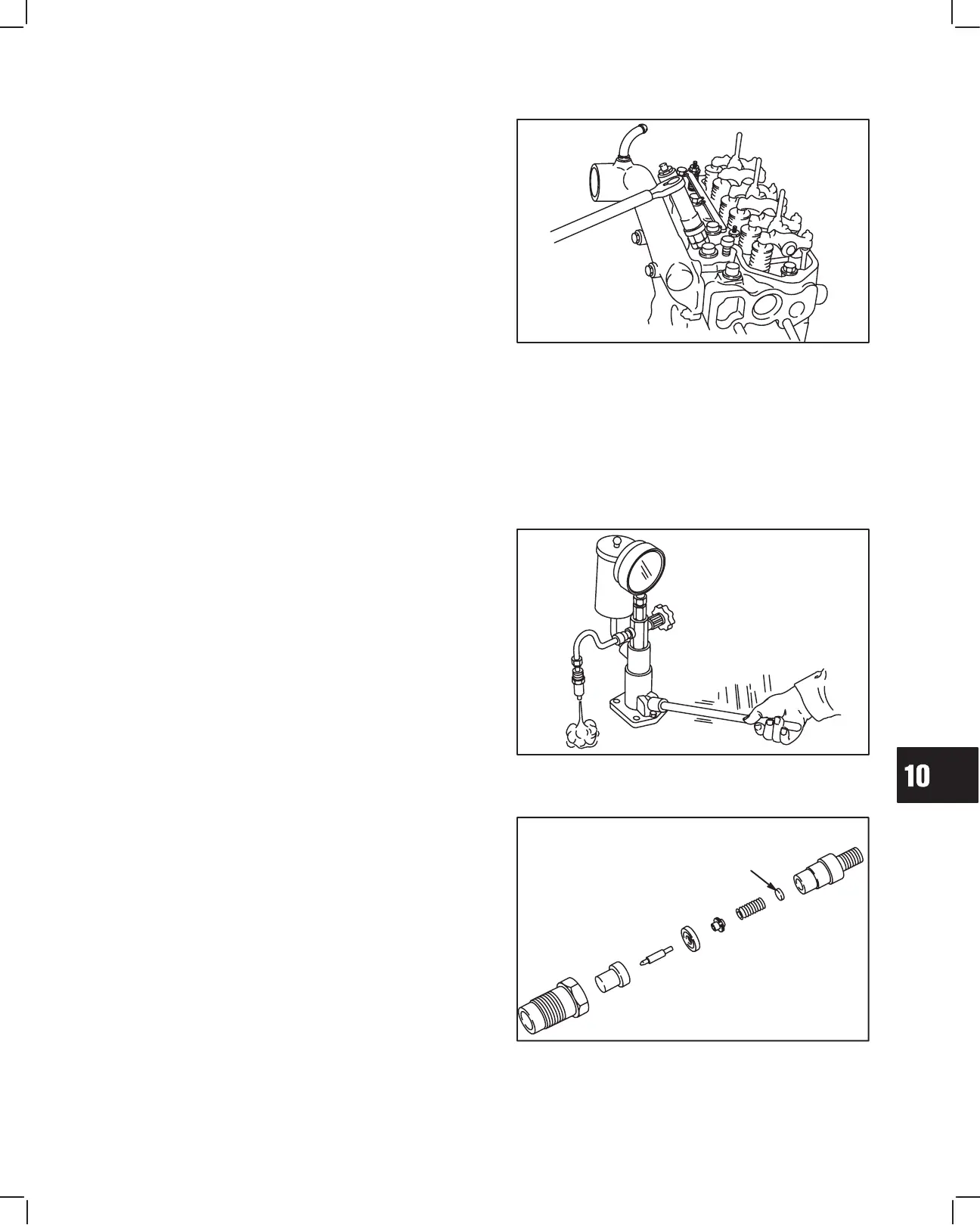

4. Remove injector nozzles, Fig. 13.

a. Discard injector gaskets.

NOTE: Handle injectors with extreme care. Do

not drop!

Always use new fuel return line and injector nozzle

gaskets when servicing fuel system.

Fig. 13 – Removing Injectors

Checking Injectors

Fuel injector nozzle testing requires highly specialized equipment and procedures. Consult the Yellow Pages under

Engines-Diesel-Fuel Injection Service & Parts for the nearest diesel fuel injection specialist.

The procedures and specifications listed are provided as an aid to the fuel injection specialist when testing injector

nozzles.

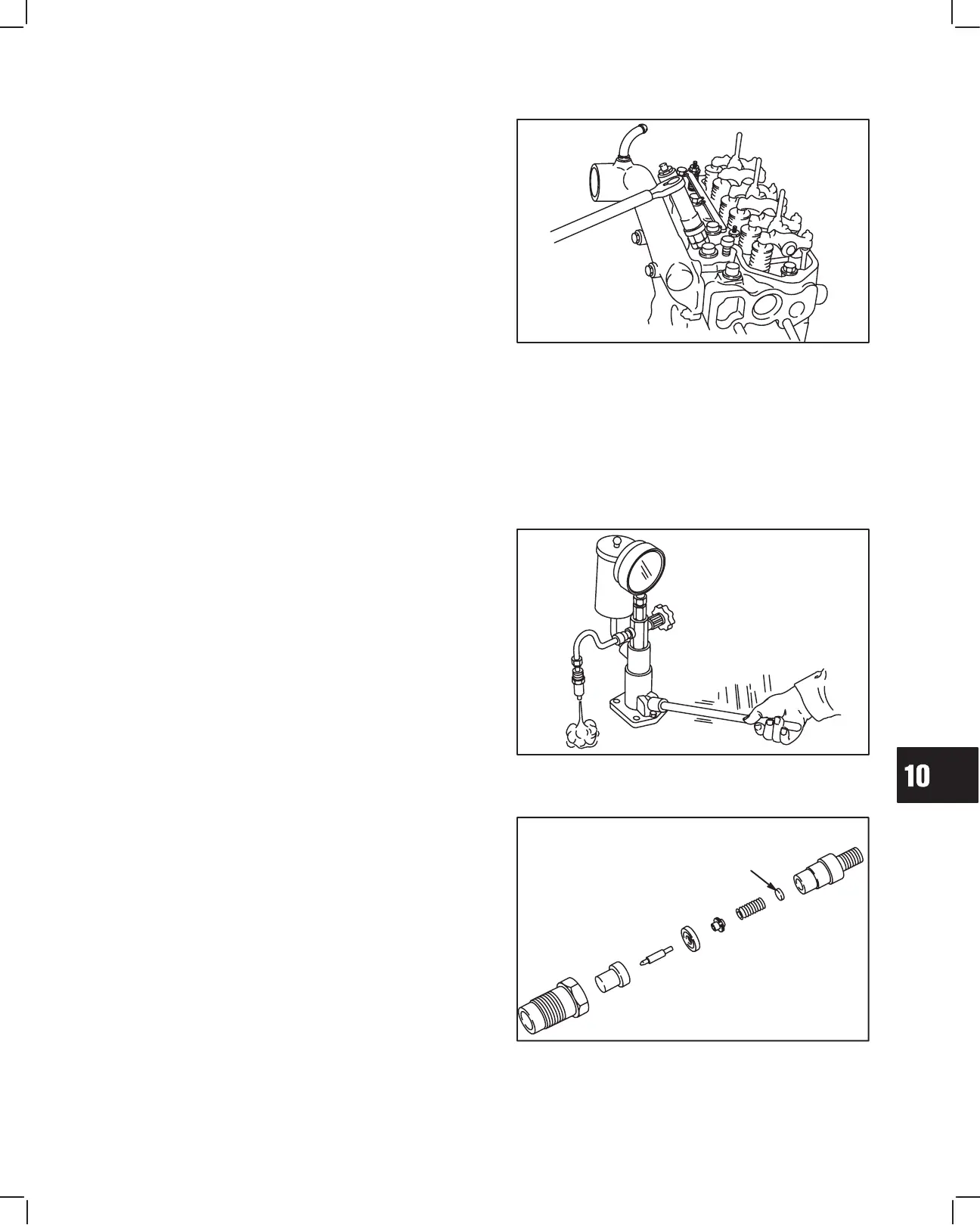

1. With injector installed on a nozzle tester, operate

the handle rapidly several times to clean off any

carbon deposits on the injector port, Fig. 14.

2. Check ‘‘pop off” pressure of injector.

Specification: 135 – 145 Bar

(1955 – 2100 psi)

Fig. 14 – Checking Injector

If injector is not within specification, the injector shim

may be changed, Fig. 15.

Replacement shims are available in .025 mm incre-

ments from .7 to 1.95 mm.

NOTE: As the shim thickness increases or de-

creases by .025 mm, injection pressure

will vary about 5 Bar (71 psi).

Torque nozzle holder and injector body to 47.0 Nm

(35 ft. lbs.).

Fig. 15 – Injector Shim

SHIM

Loading...

Loading...