Maintenance Guidelines

Introduction

This section describes what is required for printer maintenance.

Equipment

• Foam Tipped Swab (3010118211)

• Flush (3010106646 Flush UV 1 Litre)

• Bottle-HDPE 125ml for flush (3010105433)

• Isopropyl alcohol (IPA)

• Cloth-Poly Wipe 10cm x 10cm (lint-free)

CAUTION

Wear gloves when contact with ink or maintenance materials is possible. Gloves should always

overlap sleeves. Follow the ink related Safety Data Sheets (SDS) guidelines carefully in order to

ensure maximum safety. For example use Ansell Microflex 93-260 gloves, which offer a

protection against UV inks and flush up to one hour. Pollution with other chemicals can shorten

the protection time against UV inks and flush.

Wear eye protection as prescribed in this document when performing a task or action in this

area.

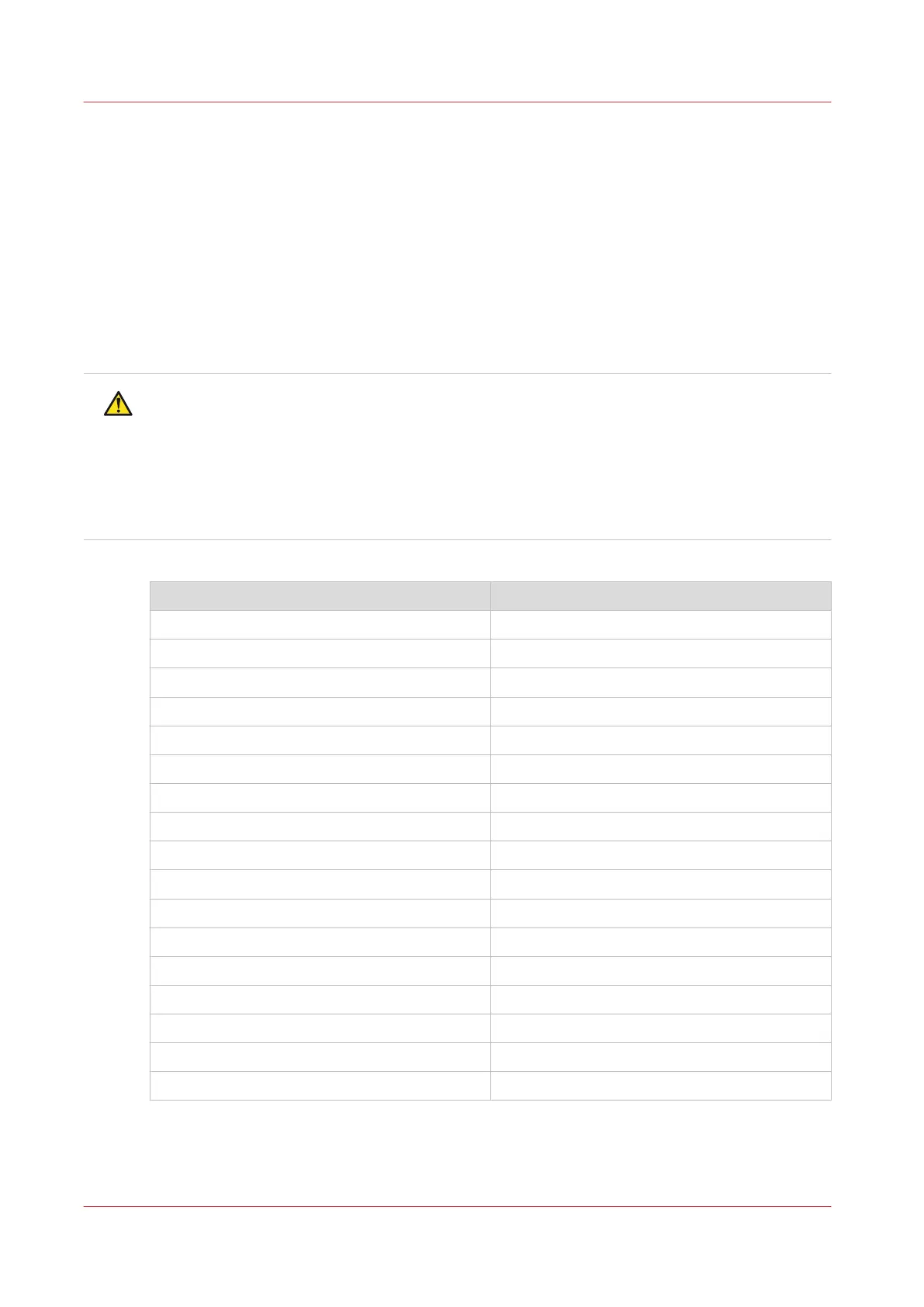

Schedule: Perform Daily maintenance at the beginning of each work day.

Procedure Frequency

AMS Printhead Maintenance Daily and as needed

Maintain White Ink Daily

Clean Horizontal Surfaces Daily

Clean Automatic Maintenance Station Daily

Clean Ink Spit Tray Daily

Clean Carriage Underside Daily

Agitate White Ink Bag Weekly

Clean printheads using swabs Weekly

Replace UV LED unit Filters Monthly or as needed

Remove Ink from Table As needed

Empty the Waste Trays Weekly or as needed

Clean UV LED unit window Monthly or as needed

Check Coolant level Monthly (fill as needed)

Clean Linear Gantry Rails Monthly or as needed

Change Ink Filters After 50 litres of ink, or if pigment looks weak

Bleed ink filter (CMYKcm) After 5 Bags

Bleed ink filter (White) After 1 Bag

Maintenance Guidelines

180 Chapter 11 - Maintenance

Loading...

Loading...