Installation Manual ED34-862

72 FXFQ-P

3P161684-3B

English 12

•

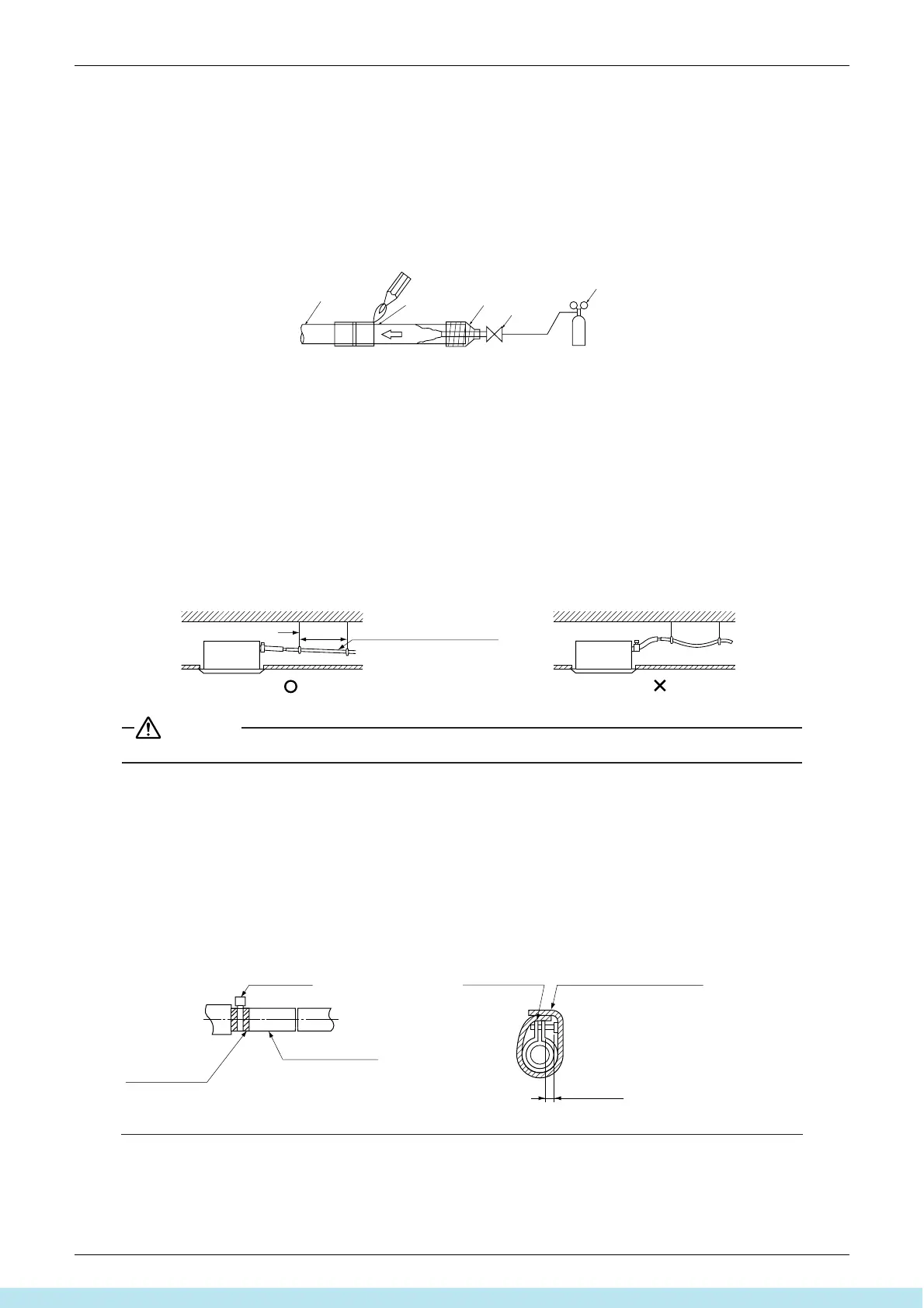

Before brazing local refrigerant piping, nitrogen gas shall be blown through the piping to expel air from the piping.

If you brazing is done without nitrogen gas blowing, a large amount of oxide film develops inside the piping, and

could cause system malfunction.

• When brazing the refrigerant piping, only begin brazing after having carried out nitrogen substitution or

while inserting nitrogen into the refrigerant piping. Once this is done, connect the indoor unit with a flared

or a flanged connection.

• Nitrogen should be set to 0.02MPa with a pressure-reducing valve if brazing while inserting nitrogen into

the piping. (Refer to Fig. 17)

7. DRAIN PIPING WORK

(1) Rig drain piping

• As for drain work, perform piping in such a manner that water can be drained properly.

• Employ a pipe with either the same diameter or with the diameter larger (excluding the raising section) than

that of the connecting pipe (PVC pipe, nominal diameter 25mm, outside diameter 32mm).

• Keep the drain pipe short and sloping downwards at a gradient of at least 1/100 to prevent air pockets from

forming.

• If the drain pipe cannot be sufficiently set on a slope, execute the drain raising piping.

• To keep the drain pipe from sagging, space hanging wires every 1 to 1.5m.

CAUTION

Water pooling in the drainage piping can cause the drain to clog.

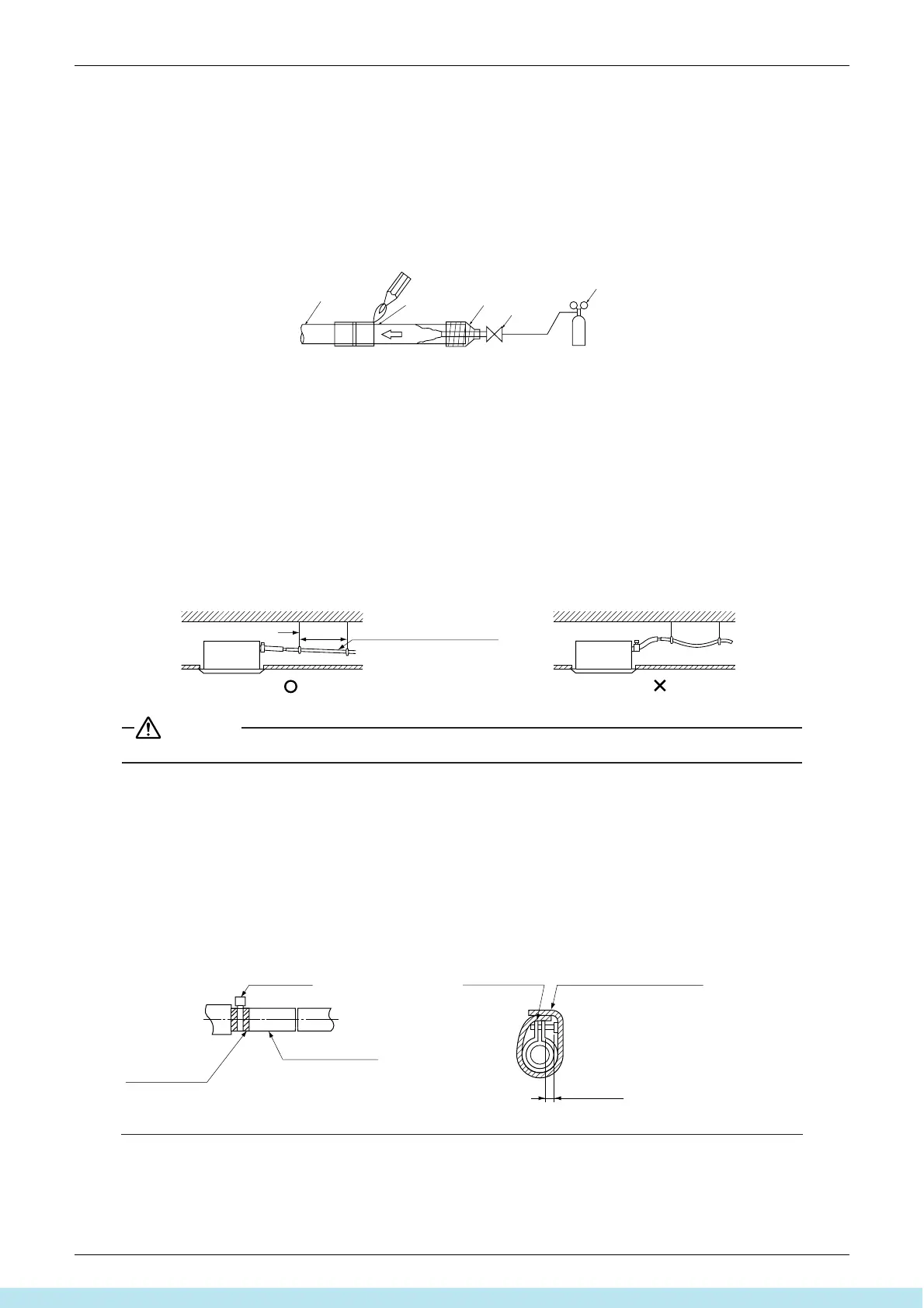

• Use the attached drain hose (1) and Metal clamp (2).

• Insert the drain hose into the drain socket up to the base, and tighten the Metal clamp securely within the

portion of a white tape of the hose-inserted tip. Tighten the Metal clamp until the screw head is less than

4mm from the hose.

• Wrap the attached sealing pad (10) over the Metal clamp and drain hose to insulate.

• Make sure that heat insulation work is executed on the following 2 spots to prevent any possible water leak-

age due to dew condensation.

• Indoor drain pipe

• Drain socket

Nitrogen

Pressure-reducing valve

Hands valve

Taping

Refrigerant piping

Part to be

brazed

Nitrogen

Fig. 17

1/100 gradient or more

1–1.5m

Fig. 18-1

GOOD

Hanger bracket

Fig. 18-2

WRONG

Metal

clamp (2)

Tape (White)

Drain hose (1)

Fig. 19

Metal

clamp (2)

Large sealing pad (10)

(accessory)

(accessory)

4mm

Fig. 20

≥

Все каталоги и инструкции здесь: http://splitoff.ru/tehn-doc.html

Loading...

Loading...