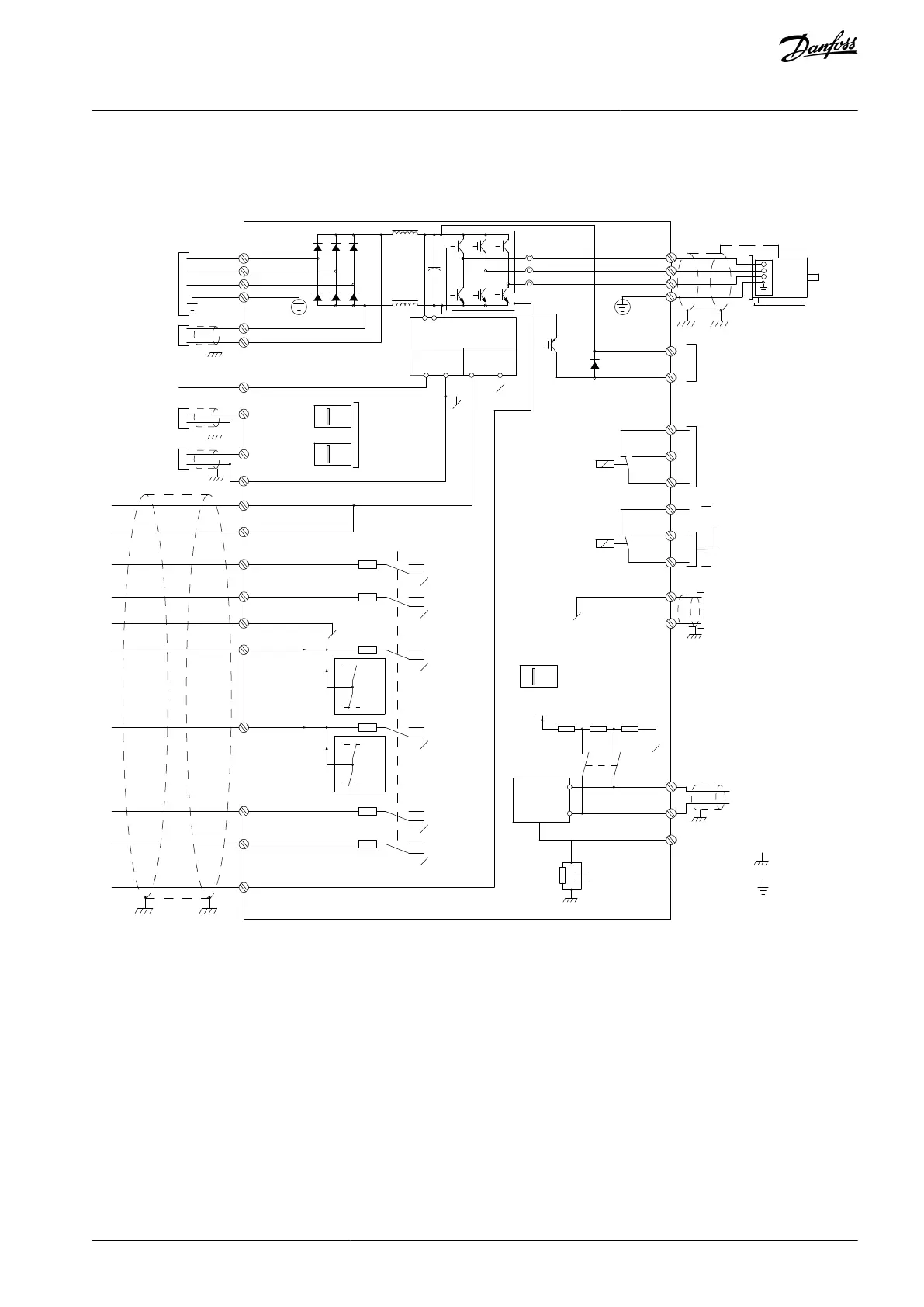

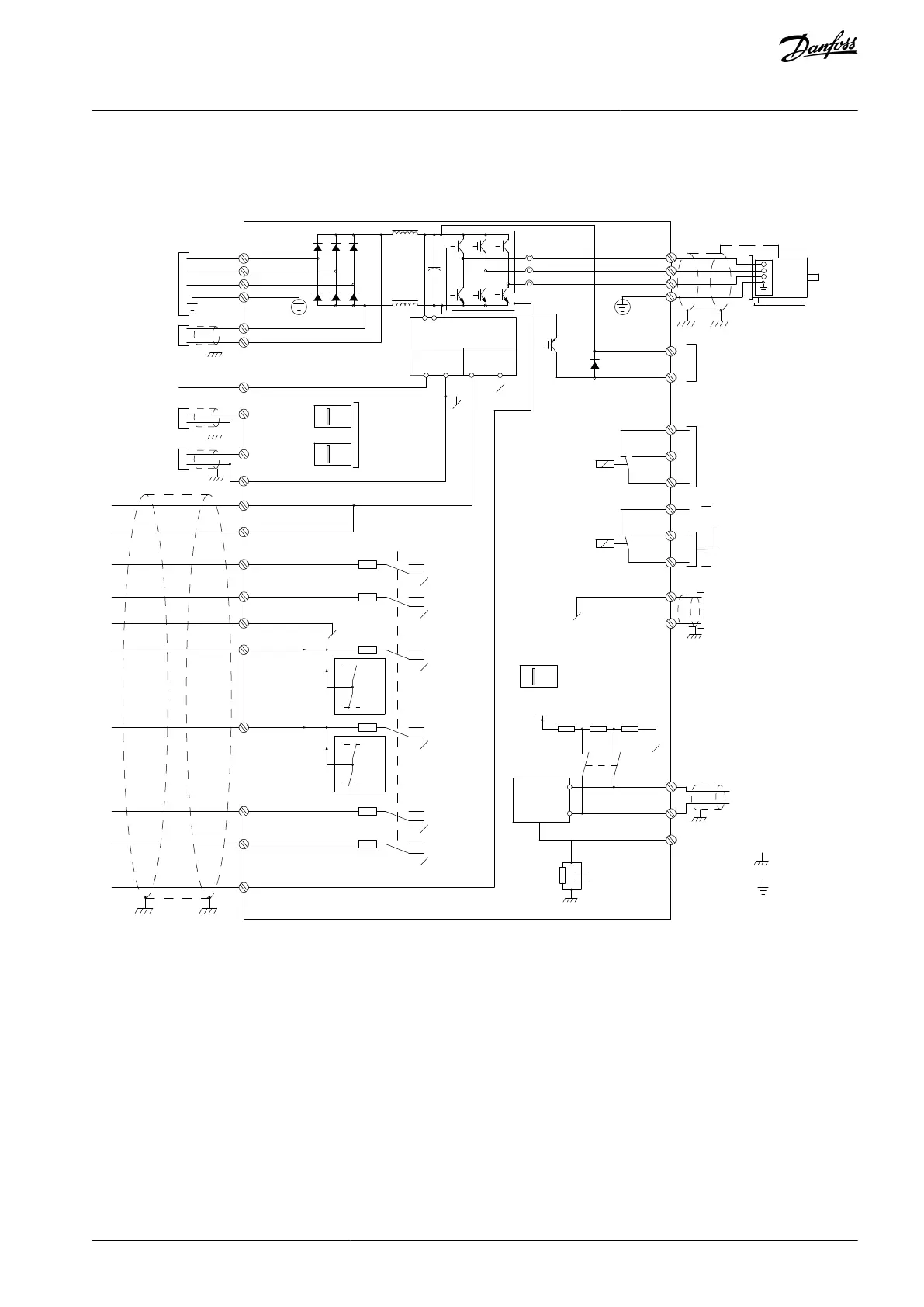

3 Electrical Diagrams

3.1 Wiring Schematic

Power Supply

Motor

Analog Output

Interface

relay 1

relay 2

ON=Terminated

OFF=Open

Brake

resistor

e30bc931.13

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

12 (+24 V OUT)

13 (+24 V OUT)

37 (D IN)

18 (D IN)

20

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0V

5V

S801

0/4-20 mA

RS485

RS485

03

+10 V DC

0/-10 V DC -

+10 V DC

+10 V DC

0/4-20 mA

0/-10 V DC -

240 V AC, 2 A

24 V DC

02

01

05

04

06

240 V AC, 2 A

24 V (PNP)

0 V (NPN)

0 V (NPN)

24 V (PNP)

24 V

0 V

(D IN/OUT)

0 V (NPN)

24 V (PNP)

(D IN/OUT)

0 V

24 V

24 V (PNP)

0 V (NPN)

0 V (NPN)

24 V (PNP)

1 2

ON

S201

ON

21

S202

ON=0/4-20 mA

OFF=0/-10 V DC -

+10 V DC

95

400 V AC, 2 A

Par. 5-00

21

ON

S801

(R+) 82

(R-) 81

: Chassis

: Earth

1)

2)

1)

Illustration 1: Wiring Schematic

A=Analog, D=Digital

1) Do not connect cable shield.

Terminal 37 is used for Safe Torque Off (STO). For STO installation instructions, refer to the VLT® Frequency Converters - Safe Torque

Off Operating Guide.

Long control cables and analog signals may in rare cases, depending on installation, result in 50/60 Hz ground loops due to noise

from mains supply cables. If 50/60 Hz ground loops occur, consider breaking the shield or insert a 100 nF capacitor between shield

and enclosure.

To avoid ground currents from both groups to affect other groups, connect the digital and analog inputs and outputs separately to

the common inputs (terminals 20, 55, and 39) of the drive. For example, switching on the digital input may disturb the analog input

signal.

AU275636650261en-000101 / 130R0334 | 15Danfoss A/S © 2022.12

Electrical Diagrams

VLT AutomationDrive FC 301/302

Programming Guide

Loading...

Loading...