DV11

Operation and Maintenance

143

Common Rail Fuel-injection System

Printed in Mar. 2005 PS-MMA0608-E1A

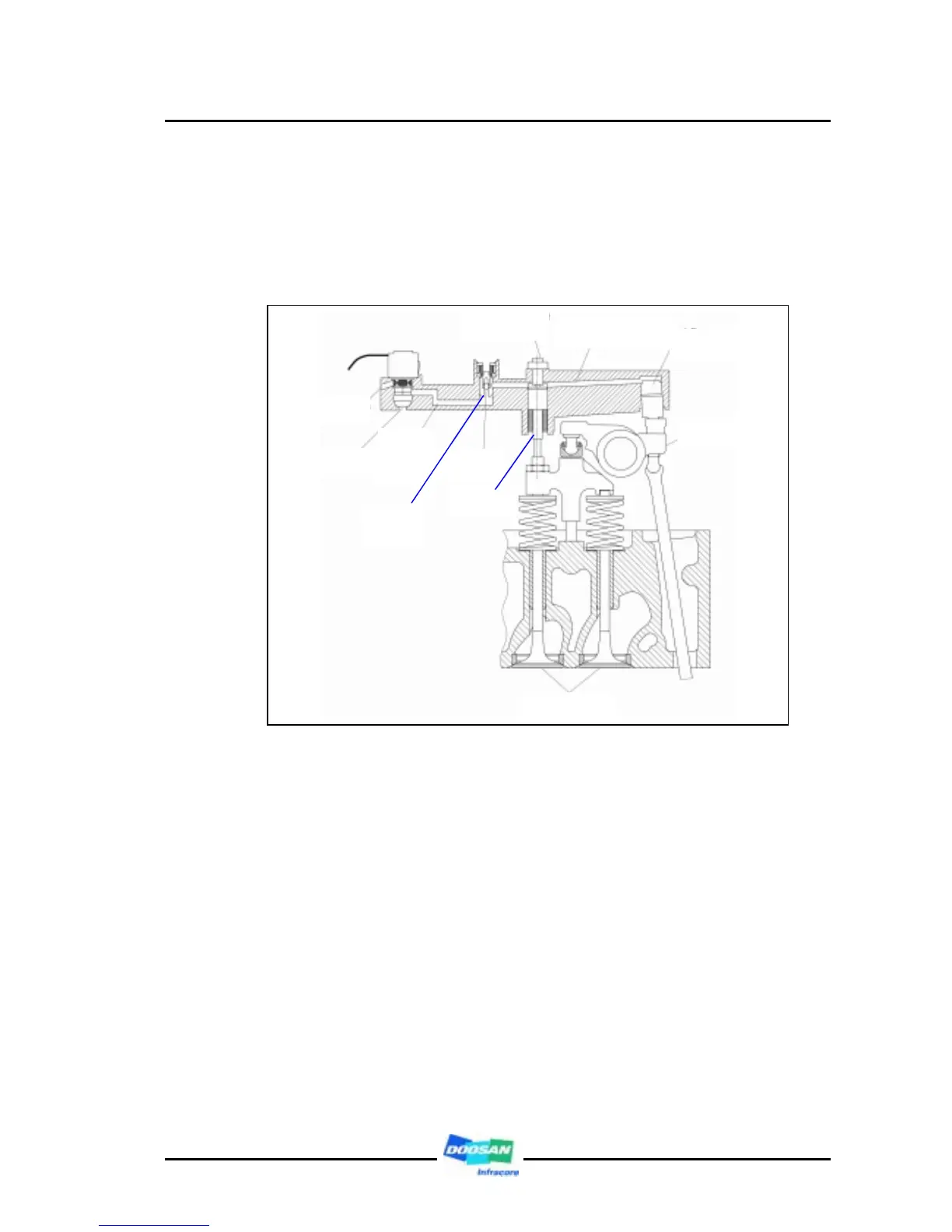

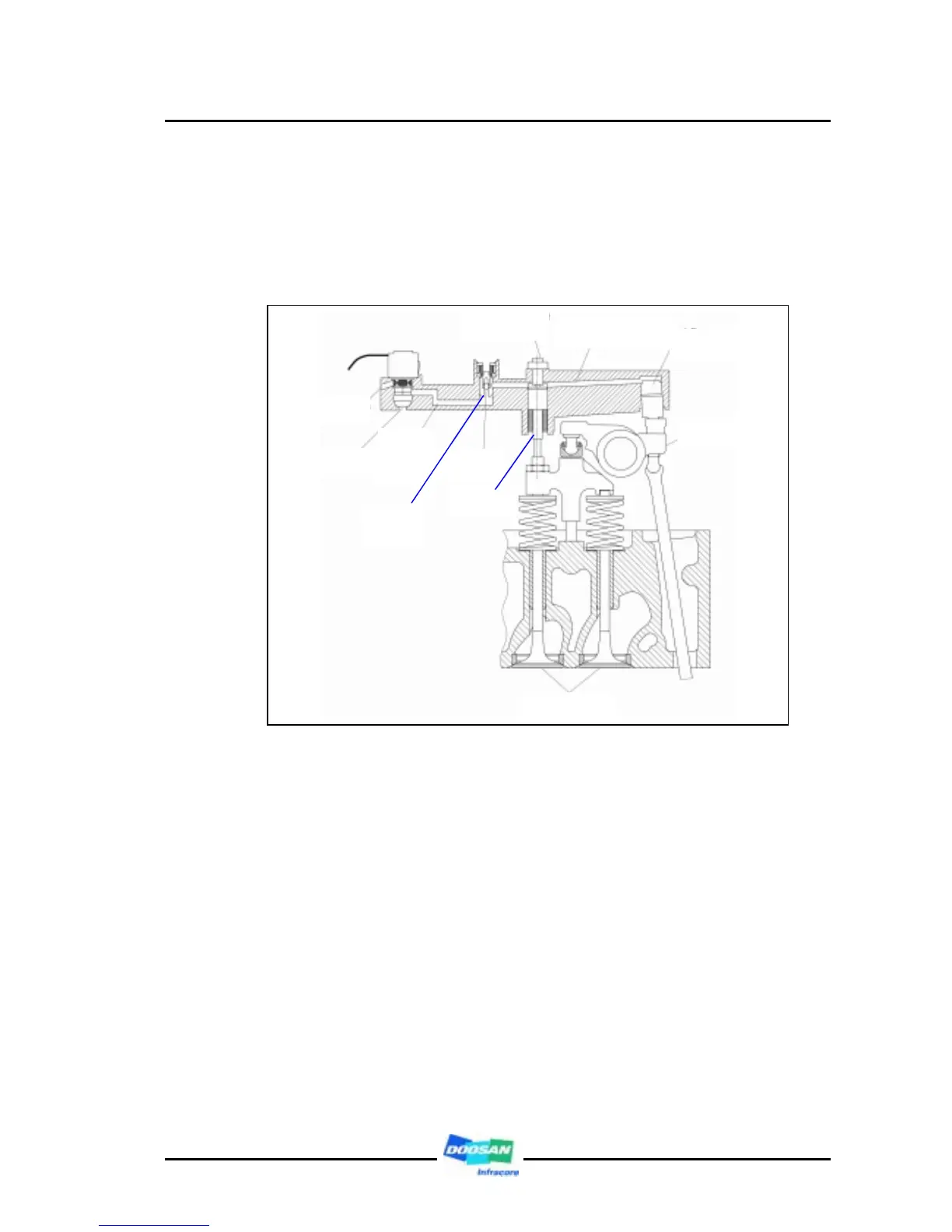

3.6.2. Theory of operation

z Energizing the engine brake effectively converts a power producing diesel engine

into a power absorbing air compressor. This is accomplished by opening the

cylinder’s exhaust valve (A) near the top of the normal compression stroke,

releasing the compressed cylinder charge back into the atmosphere.

z The blow-down of the compressed cylinder charge to atmosphere prevents return

of the stored energy to the piston on the expansion stroke. The effect is a net

energy loss, since the work done in compressing the cylinder charge is not

returned to the crankshaft during the expansion stroke. The energy being lost is

slow the vehicle on level roads and help control vehicle speeds on downhill

grades.

z The power required to operate the brake is obtained from the engine’s camshaft

and rocker arms (B). The motion of the exhaust rocker arm is utilized to open the

exhaust valve and blow-down the cylinder.

z Energizing the solenoid valve (C) permits engine lube oil to flow under pressure

(D, E) through the control valve to both the master piston (G) and slave piston (H).

z Oil pressure causes the master piston (G) to move down, coming to rest on the

corresponding exhaust rocker arm (B).

Slave piston

(H)

Adjusting screw

(L)

Oil inlet

(D)

Solenoid valve

(C)

Control valve

(F)

Check valve

(K)

Low

pressure oil

(E)

High pressure oil

(J)

Exhaust rocker arm

(B)

Master piston

(G)

Exhaust valve

(A)

Loading...

Loading...