DV11

Operation and Maintenance

199

Maintenance of Major Components

Printed in Mar. 2005 PS-MMA0608-E1A

(T) = 0.015 x S (about 1.5mm per 100mm).

T = 0.015 x *S (mm)

(T : Deflection, S : Span)

*

C : Distance of pulleys (mm)

D : Large pulley diameter (mm)

d : Small pulley diameter (mm)

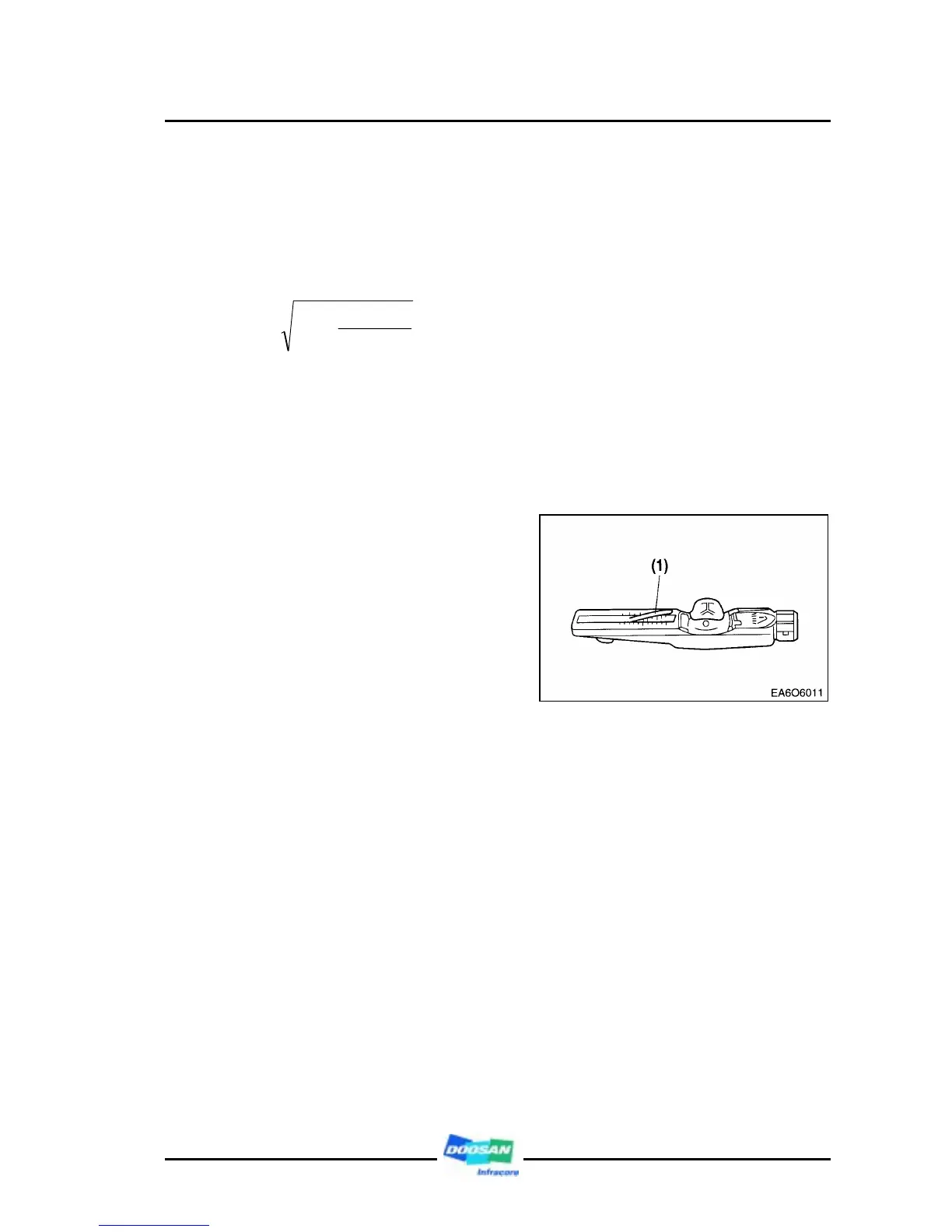

(4) Measuring tension

① Lower indicator arm (1) into the

scale

z Apply tester to belt at a point

midway between two pulleys

so that edge of contact

surface (2) is flush with the V-

belt.

z Slowly depress pad (3) until

the spring can be heard to

disengage. This will cause

the indicator to move

upwards.

z If pressure is maintained after

the spring has disengaged a

false reading will be obtained.

2

)(

2

2

dD

CS

−

−=

(mm)

Loading...

Loading...