DV11

Operation and Maintenance

198

Maintenance of Major Components

Printed in Mar. 2005 PS-MMA0608-E1A

z Knocking out dirt by hand

- In emergencies, when no

compressed air or cleaning agent

is available, it is possible to clean

the filter cartridge provisionally by

hitting the end disk of the cartridge

with the ball of one's thumb.

- Under no circumstances should

the element be hit with a hard

object or knocked against a hard

surface to loosen dirt deposits.

z Checking the air cleaner cartridge

- Before reinstalling the cartridge, it must be checked for damage e.g. to the paper

pleats and rubber gaskets, or for bulges and dents etc. in the metal jacket.

- Damaged cartridges should not be reused under any circumstances. In cases of

doubt, discard the cartridge and install a new one.

5.5. Belt

The tension of the belts should be checked after every 2,000 hours of operation.

(1) Change the belts if necessary

If in the case of a multiple belt drive, wear or differing tensions are found, always

replace the complete set of belts.

(2) Checking condition

Check belts for cracks, oil, overheating and wear

(3) Testing by hand

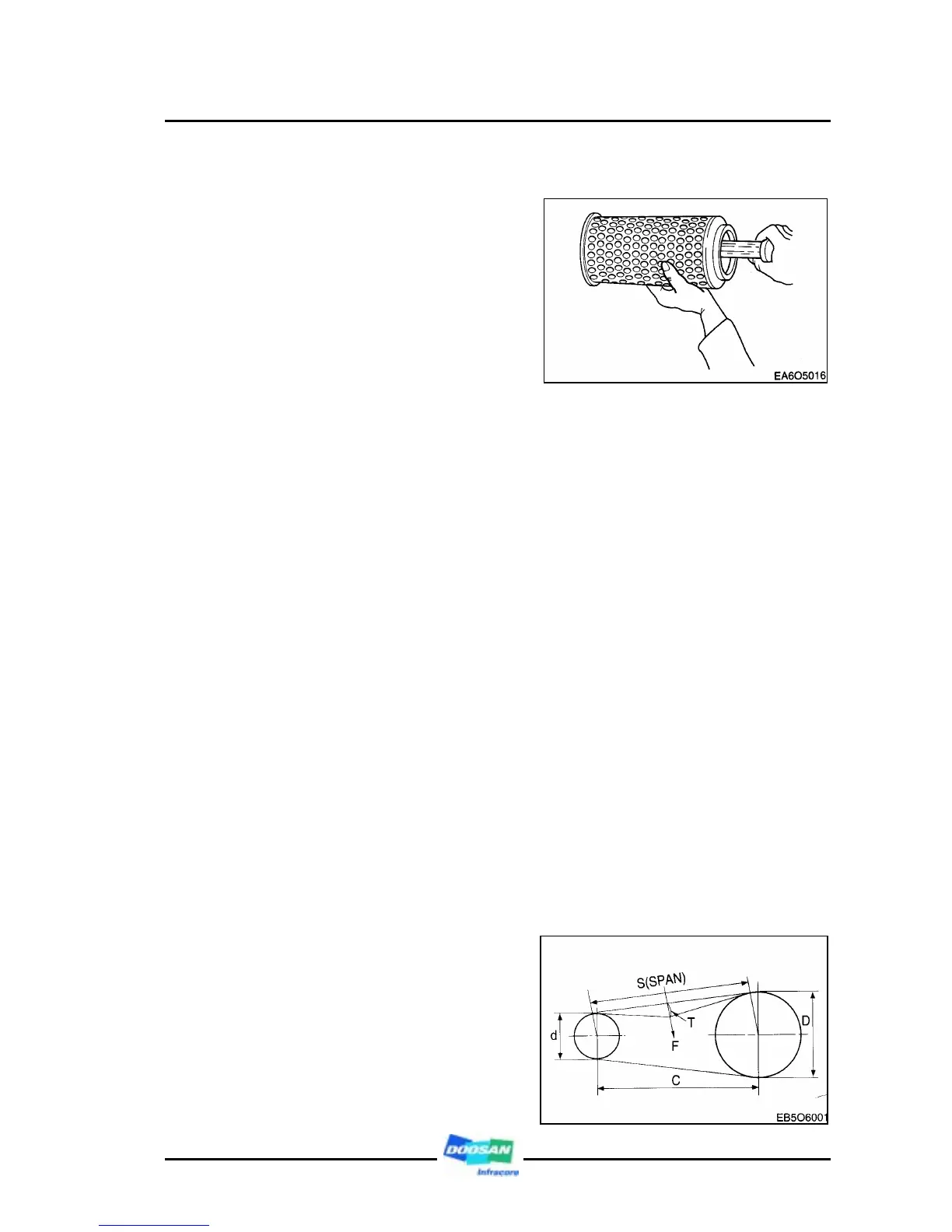

z Poly belt

Poly belt will be properly

tensioned if the deflection force

“F” is applied mid-way between

the belt’s tangent points with the

pulley.

Loading...

Loading...