Maintenance of Major Components

- 114 -

z

OVERSPEED shutdown setting

DWC-2000 has a Test switch to determine the OVERSPEED set point and test the engine shutdown

function. If you want to adjust the OVERSPEED set point at the speed about 10 % higher than the

RUN set speed, use the Test switch. When the engine is operating at the Run set speed in pushing

the Test switch, rotate the Overspeed Adjust. by CCW until the Overspeed shutdown function is

operated. When the Test switch is pushed, the Overspeed set point is reduced to 10/11 of the real

set point.

z

RUN ramp turn-On speed setting

When the engine is operating at the Run set speed, adjust the Run lamp adjustment CCW until the

lamp is on. Then, more rotate 1/2 turn by CCW.

z

CRANK ramp turn-on speed setting

When the engine is operating at the Idle set speed(800 rpm), adjust the Crank lamp adjustment

CCW until the lamp is on. Then, more rotate 1.5 turns by CCW.

5.1.8. System troubleshooting

z

System Inoperative

If the engine governing system does not function, the fault may be determined by performing the

voltage tests described in steps 1,2,3 and 4. (+) and (

–

) refer to meter polarity. Should normal values

be indicated as a result of following the trouble shooting steps, the fault may be with the actuator or

the wiring to the actuator. See the actuator publication for testing details.

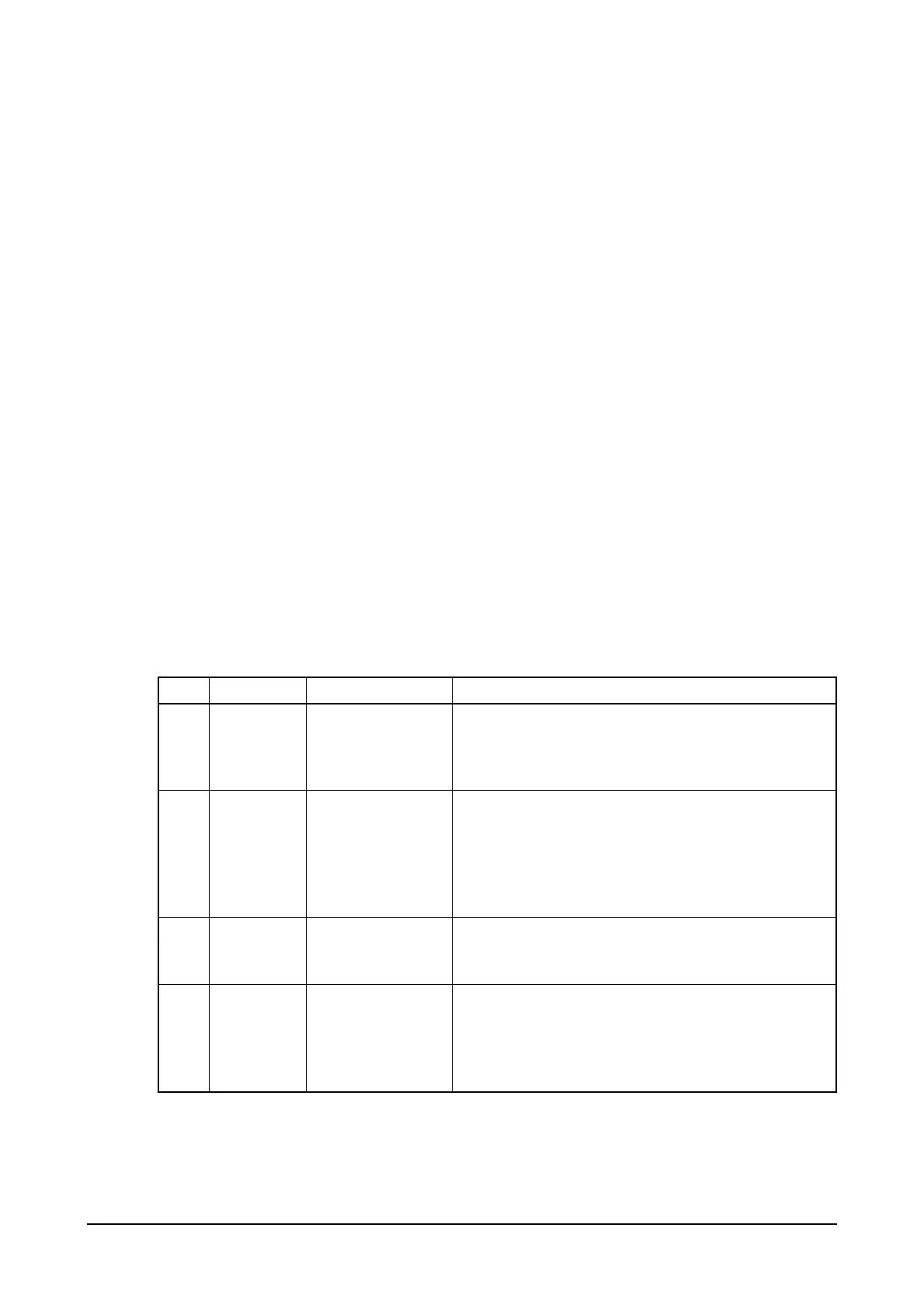

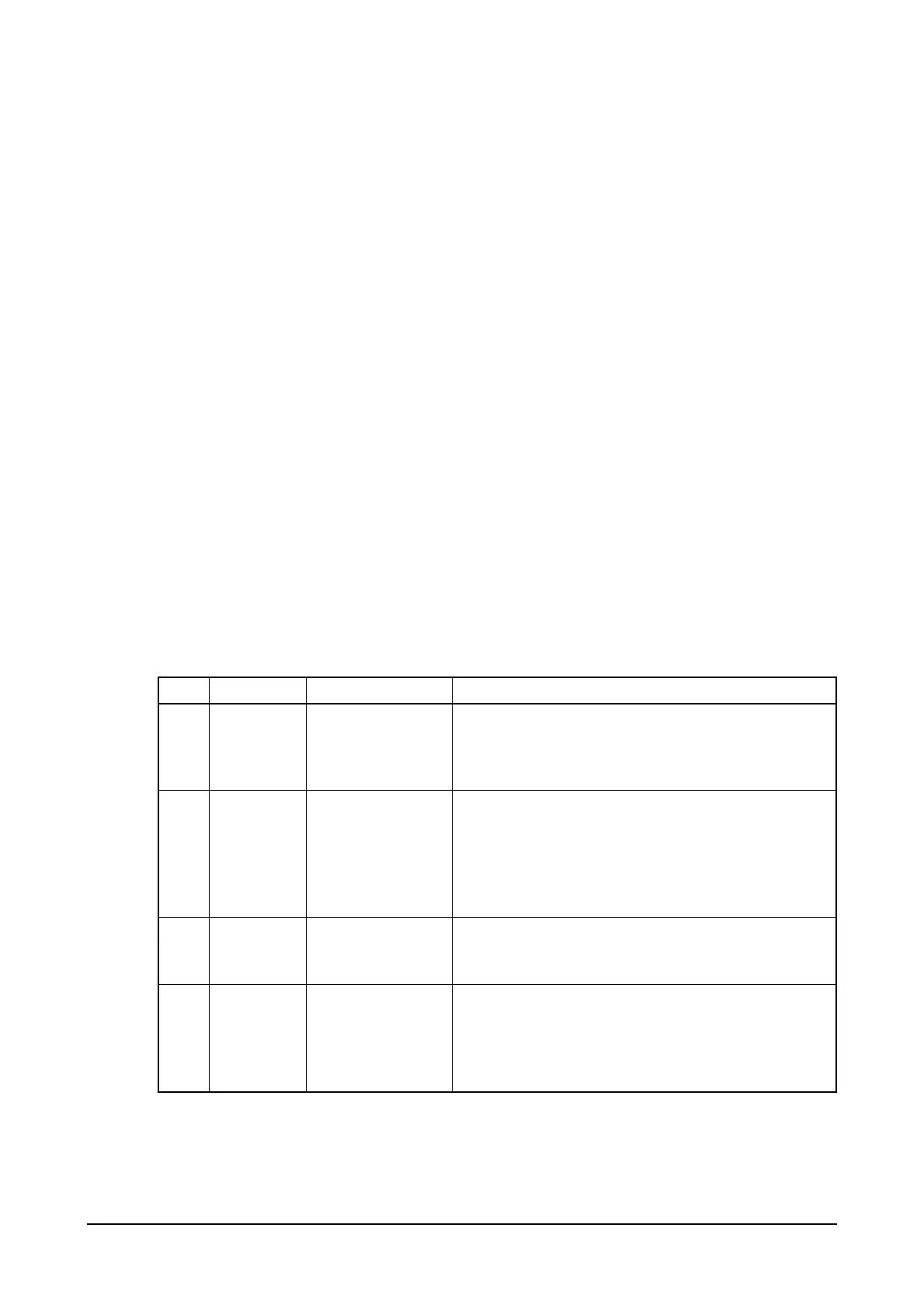

Step Terminals Normal value Probable cause of abnormal reading

1 F(+) & E(-)

Battery supply

voltage(24V)

1. DC battery power not connected.

Check for blown fuse.

2. Low battery voltage.

3. Wiring error.

2C & D

1.0 VAC RMS min.,

while cranking

1. Gap between speed sensor and gear teeth too great.

Check gap.

2. Improper or defective wiring to the speed sensor.

Resistance between terminals C and D should be 30

to 1,200 ohms

3. Defective speed sensor.

3 P(+) & G(-)

10 VDC

internal supply

1. Short on terminal P.

(This will cause a defective unit.)

2. Defective speed control.

4 F(+) & A(-)

1.0 – 2.0 VDC

while cranking

1. SPEED adjustment set too low.

2. Short / open in actuator wiring.

3. Defective speed control.

4. Defective actuator.

See actuator troubleshooting.

Loading...

Loading...