Inspection

- 72 -

3.2.6. Crankshaft

1) Inspection and measurement

z

Inspect for any scratch or damage

with naked eyes, and grind to the

undersize according to the damaged

degree and use the undersized

bearing.

z

Inspect for any crack by means of

magnetic powder and color check,

and replace the cracked ones.

a) Journal and pin diameter

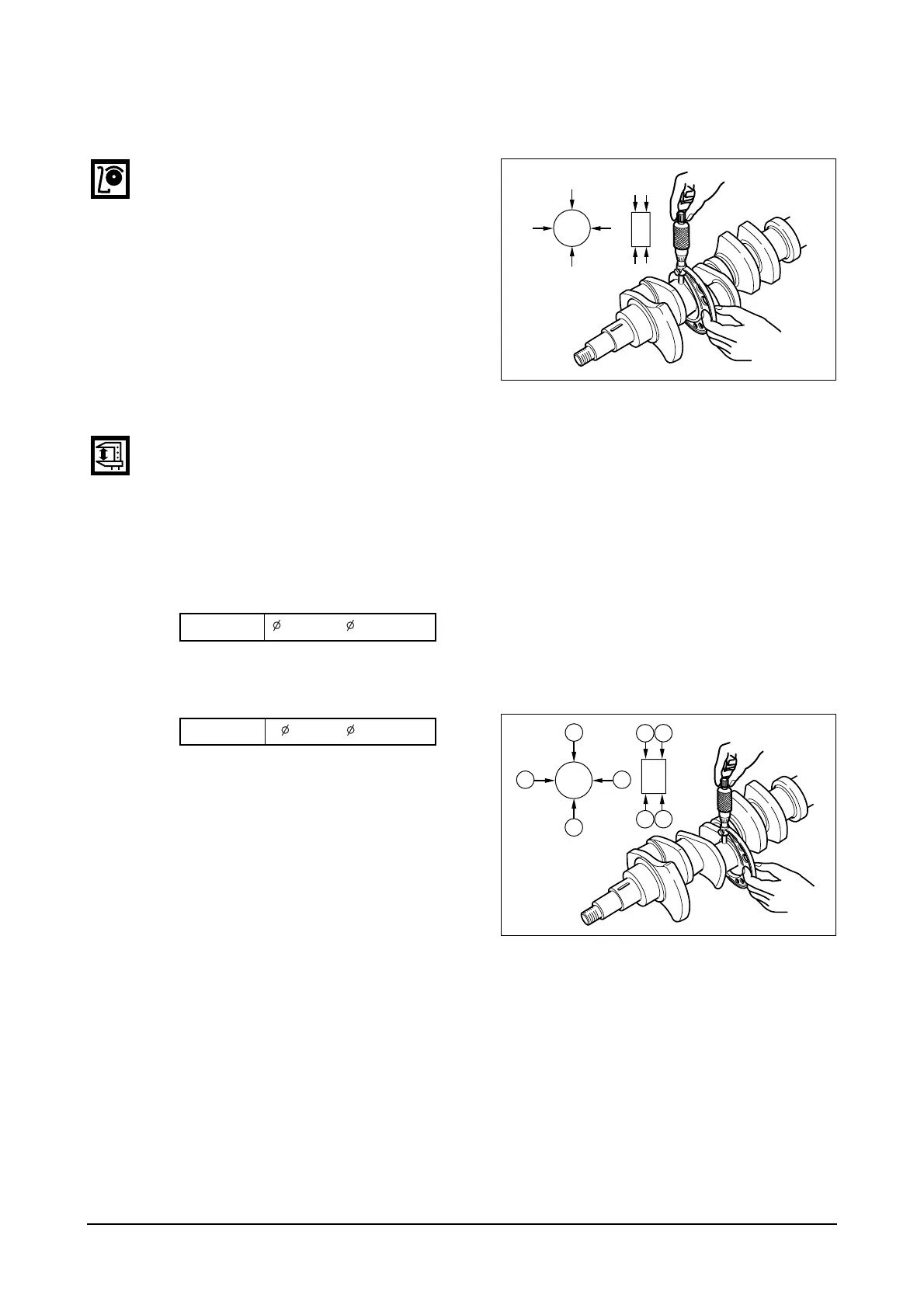

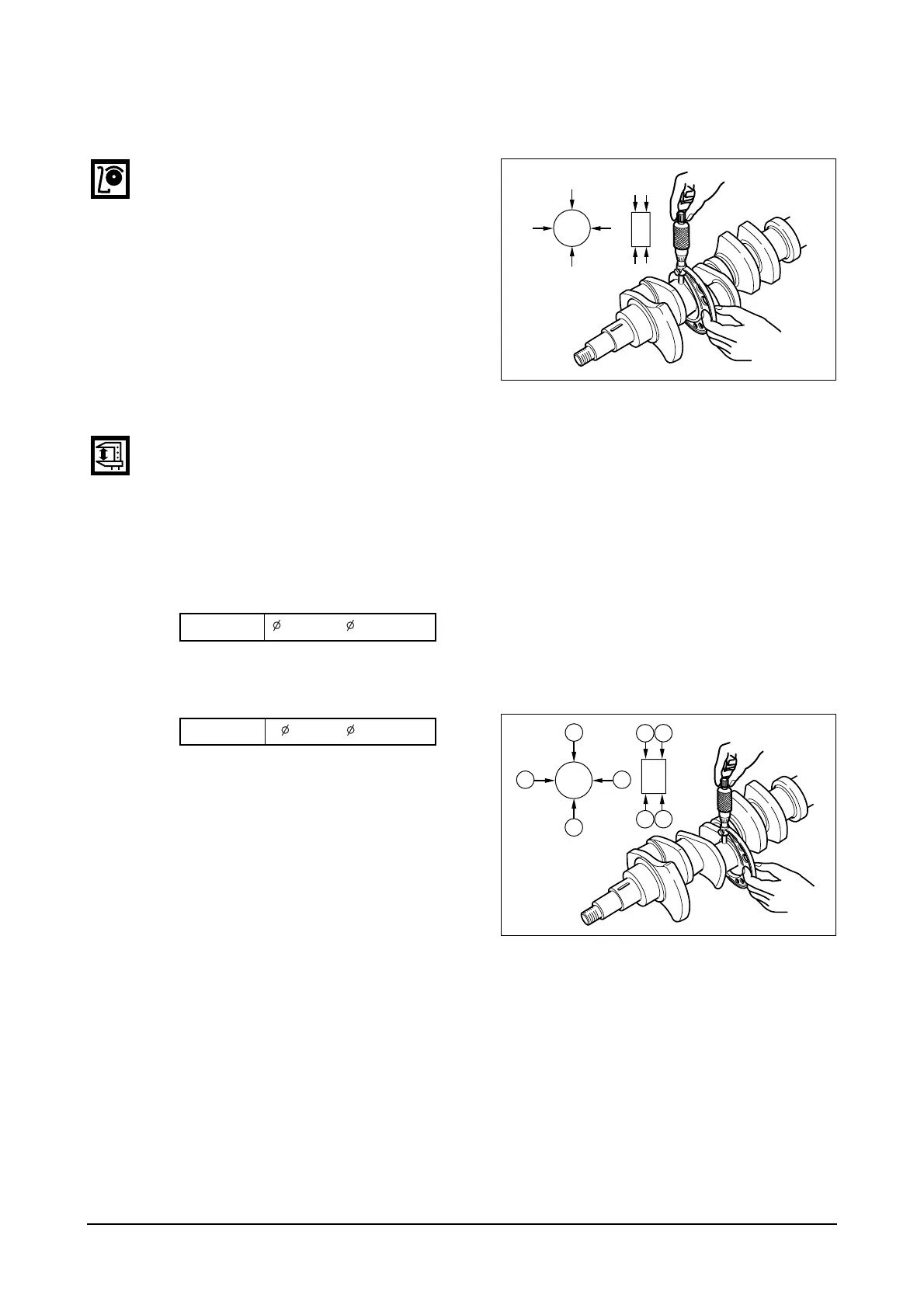

z

With outside micrometer, measure

the outside diameter of crank

journal and crank pin at the

direction and position of the figure

shown and take the wear.

<Crankshaft journal outside diameter>

<Crankshaft pin outside diameter>

z

In case that the lopsided wear is

more than the limit value, grind to

the undersize, and use the

undersized bearing.

<Kinds of bearings for undersize>

(a) Standard

(b) 0.25 (Inside diameter 0.25 mm less than standard)

(c) 0.50 (Inside diameter 0.50 mm less than standard)

(d) 0.75 (Inside diameter 0.75 mm less than standard)

(e) 1.00 (Inside diameter 1.00 mm less than standard)

Standard 103.98 ~ 104.00 mm

Standard 89.98 ~ 90.00 mm

A

A

BB

EA3M2050

I

II

1

1

2

EA0M4017

2

3

4

3

4

Loading...

Loading...