Engine Reassembly

- 85 -

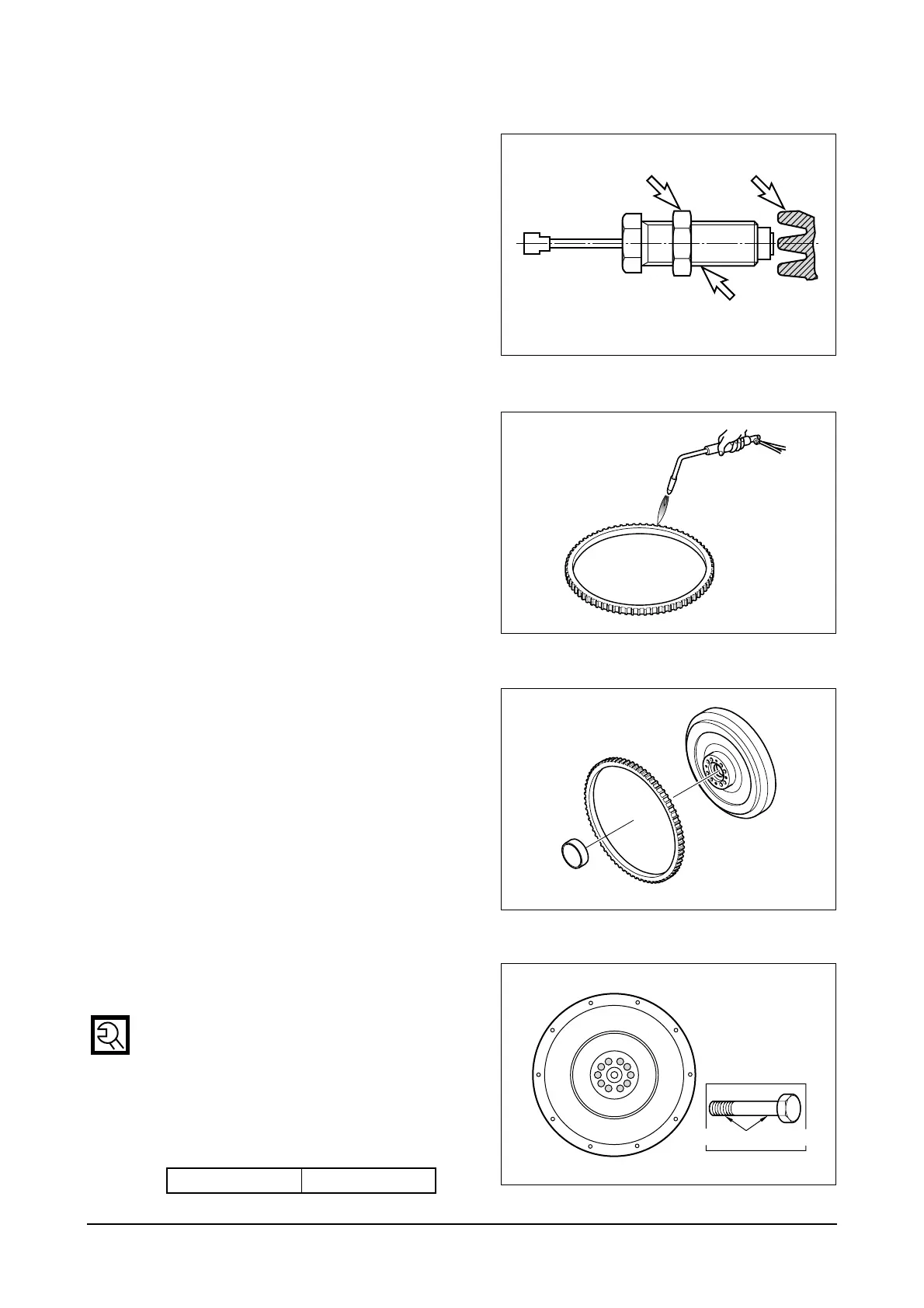

3.3.9. Tacho sensor

z

Loosen the lock nut to hexagonal side of

sensor.

z

Rotate (CW) the tacho-sensor on fly

wheel housing, until the end of it reach

on fly wheel ring gear as figure.

z

Rotate (CCW) the tacho-sensor for 270

°

(gap : about 1.0 mm) and fix the lock nut.

z

Tolerance limit is 27

°

. (gap

±

0.1 mm)

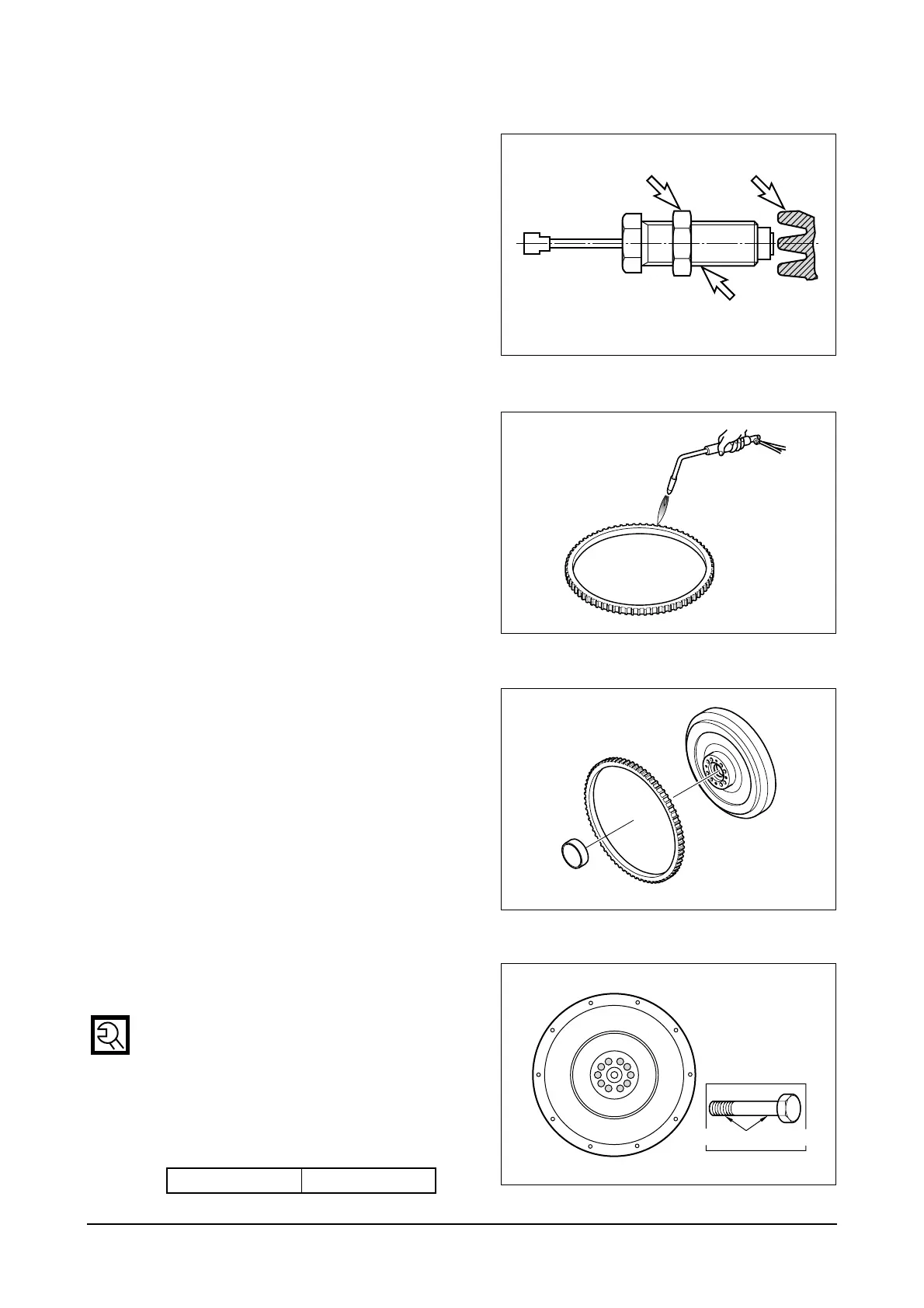

3.3.10. Flywheel

z

Installation of flywheel ring gear With a

gas burner, heat the ring gear evenly

until heat expansion takes place, then

install it using a hammer.

z

Do not allow the temperature of the ring

gear to exceed 200

°

C (390

°

F)

z

By means of mandrel, press in the wear

ring at the backward face.

z

Install two guide bolts for installing the

flywheel to the crankshaft.

z

After letting the guide pin insert through

the flywheel holes and engaging the

fixing bolts by 2 ~ 3 threads temporarily,

tighten them to the specified torque

according to lightening order. (Zigzag

order)

Torque 26 kg

⋅

m

EPM2030I

Rock nut Ring gear

M16 x 1.5

EA0M4029

EA6M2004

Wear ring Ring gear

EA6M2005

4

9 5

6 10

7

8

2

1

3

Lubricate with engine oil

Loading...

Loading...