Inspection

- 63 -

3.2.3. Cylinder head

z

Carefully remove carbon from the lower face of the cylinder head using nonmetallic material to

prevent scratching of the valve seat faces.

z

Check the entire cylinder head for very fine cracks or damage invisible to ordinary sight using a

hydraulic tester or a magnetic flaw detector.

1) Cylinder head disassembly

NOTE :

Be careful for the cylinder head

gasket contacting surface of

cylinder head not to be damaged.

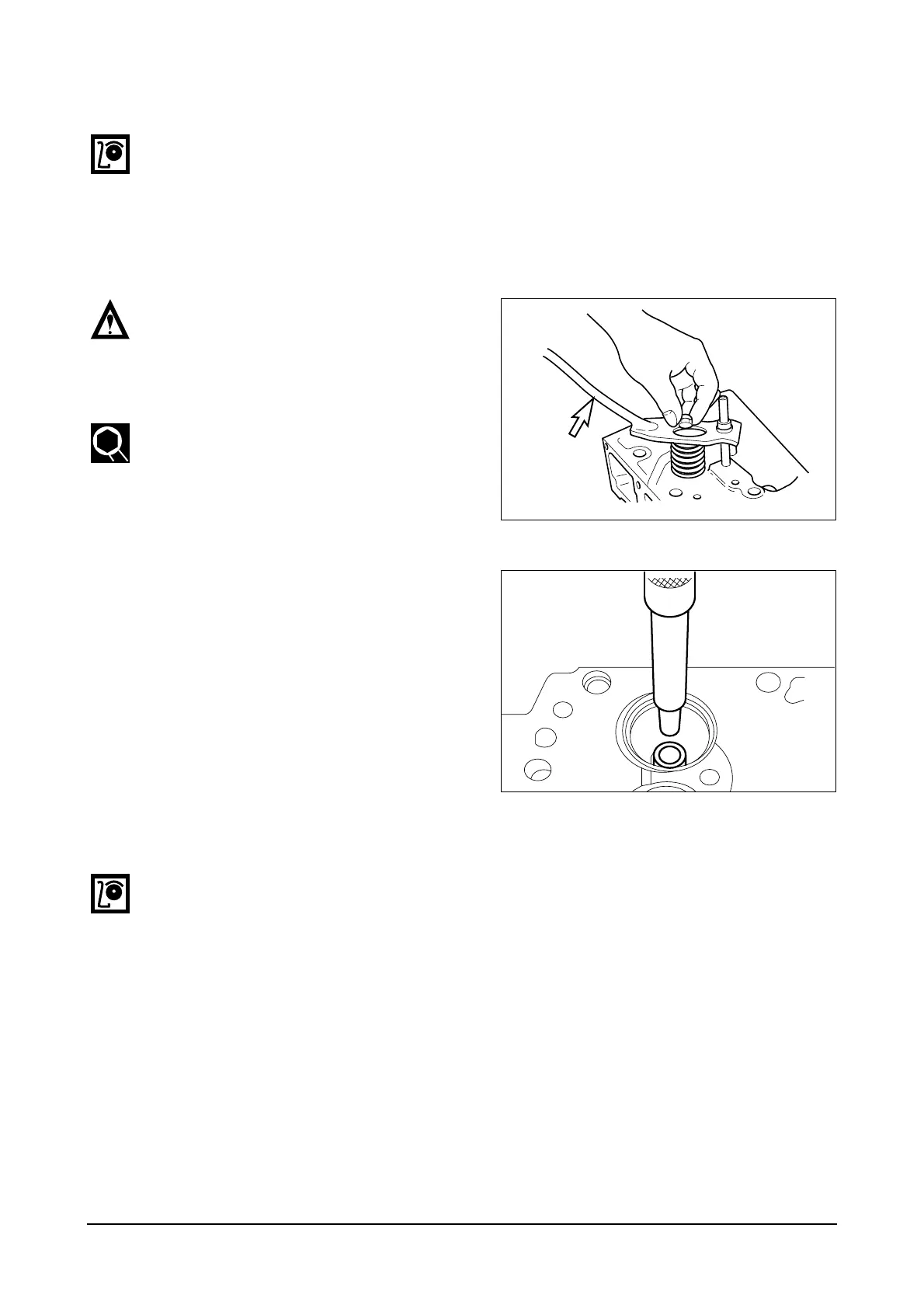

z

Remove the cotter pin pressing the

valve spring by means of a special

tool.

z

Take out the valve stem seal.

z

Pull out the intake and exhaust

valves.

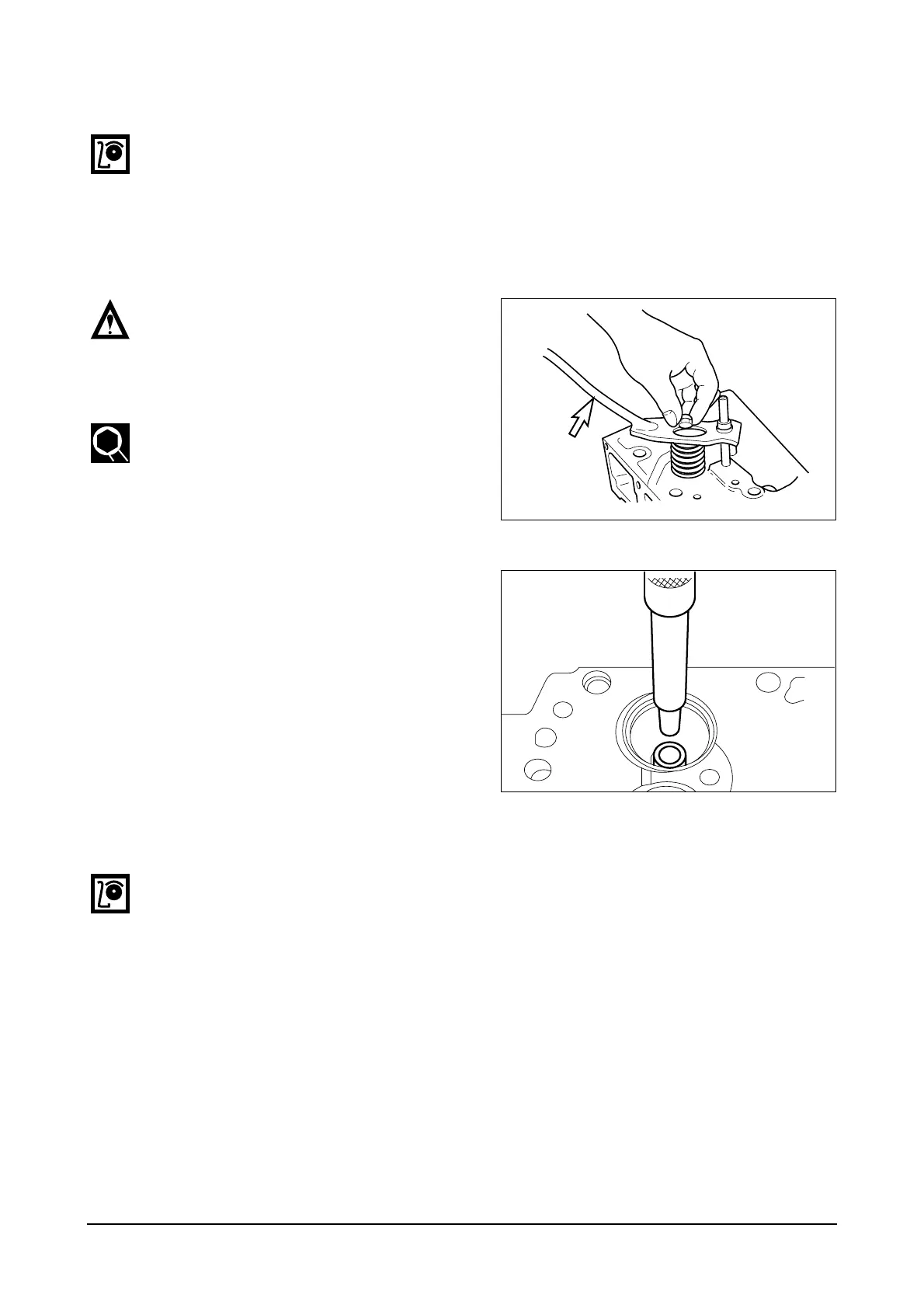

z

Remove the valve guides from the

combustion room side of cylinder

head by means of a special tool.

2) Inspection and measurement of cylinder head

a) Inspection of cracks and damage

z

Eliminate the carbon residue and gasket piece from the cylinder head lower face thoroughly.

Then be careful for the valve seat not to be damaged.

z

For cracks or damages to search difficult may be inspected by a hydraulic test or a magnetic

powder test. (Hydraulic test is same as for cylinder block.)

Valve spring

compressor

EA0M4007

EFM2034I

Loading...

Loading...