Inspection

- 73 -

z

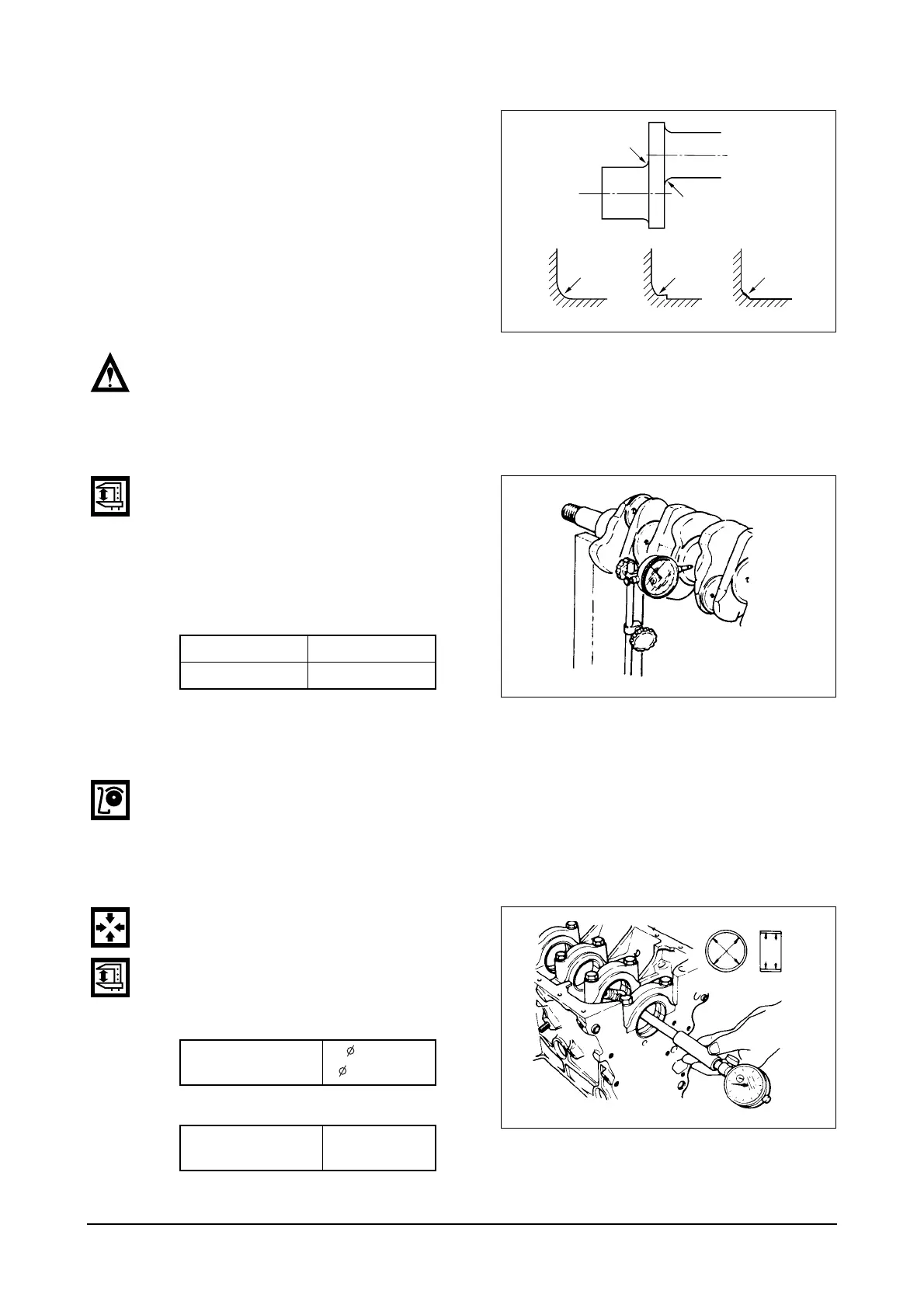

There are 4 kinds as above, and the

crankshaft also can be used by

regrinding as above.

<“R part” standard value>

①

Crank pin 'R' : 4.0

②

Crank journal 'R' : 4.0

NOTE :

In case of crankshaft regrinding, the “R part” at the end of bearing must accurately

be ground without fail and should avoid any processed jaw or coarse surface

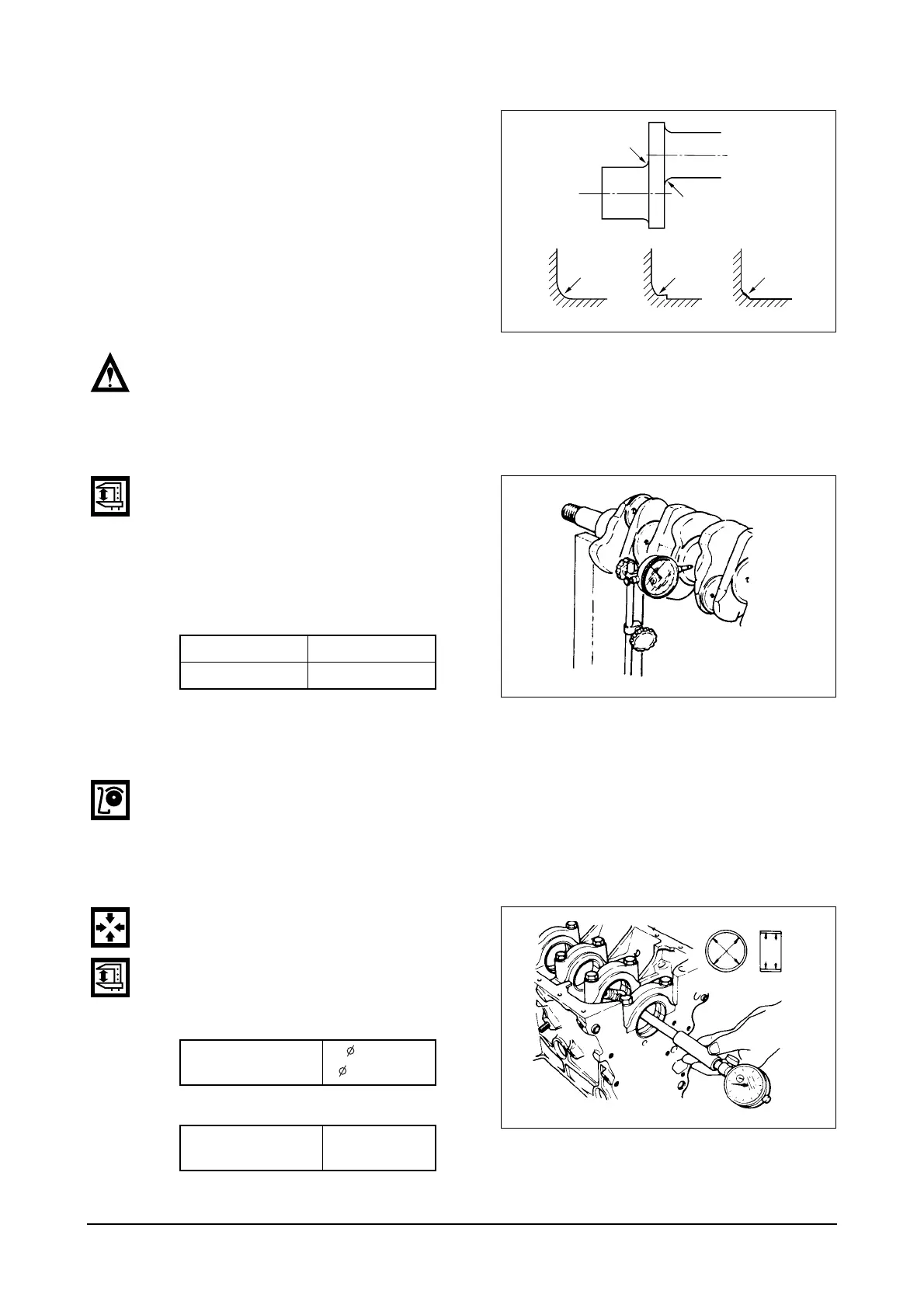

b) Run out of crankshaft

z

Place the crankshaft on the V-

block.

z

Place the dial gauge on the

surface plate and measure the run

out of crankshaft rotating the

crankshaft

2) Inspection on crankshaft bearing and connecting rod bearing Inspection

z

Inspect the crankshaft bearing and connecting rod bearing for any damages such as lopsided

wear, scratch etc. and if abnormal, replace it.

z

Inspect the oil clearance between the crankshaft and bearing.

a) How to utilize the cylinder gauge

z

Assemble the main bearing at the

cylinder block and after tightening

the bearing cap at the specified

torque, measure the inside

diameter.

Standard Limit

0.06 mm 0.4 mm

Journal bearing

nominal diameter

103.98 ~

104.00 mm

Bearing cap

Bolt torque

Initial 30 kg

⋅

m

+ angle 90

°

" R "

" R "

" R "

" R " " R "

EFM2048I

0

-0.5

0

-0.5

EA0M4023

EA0M4019

Loading...

Loading...