Inspection

- 62 -

3.2. Inspection

3.2.1. Cylinder block

1) Clean the cylinder block thoroughly and check a visual inspection for cracks or damage.

2) Replace if cracked or severely damaged, and correct if slightly damaged.

3) Check the oil and water passing lines for restriction or corrosion.

4) Inspect the cylinder block’s camshaft bush to any damage and the alignment of oil supply holes and

if abnormal or severe wears, replace it.

5) Make a hydraulic test to check for any cracks or air leaks.

Hydraulic test :

Stop up each outlet port of water and oil passages in the cylinder block, apply air

pressure of about 5 kg/cm

2

against the inlet ports, then immerse the cylinder block in

water for about 1 minute to check any leaks. (Water temperature : 70 °C)

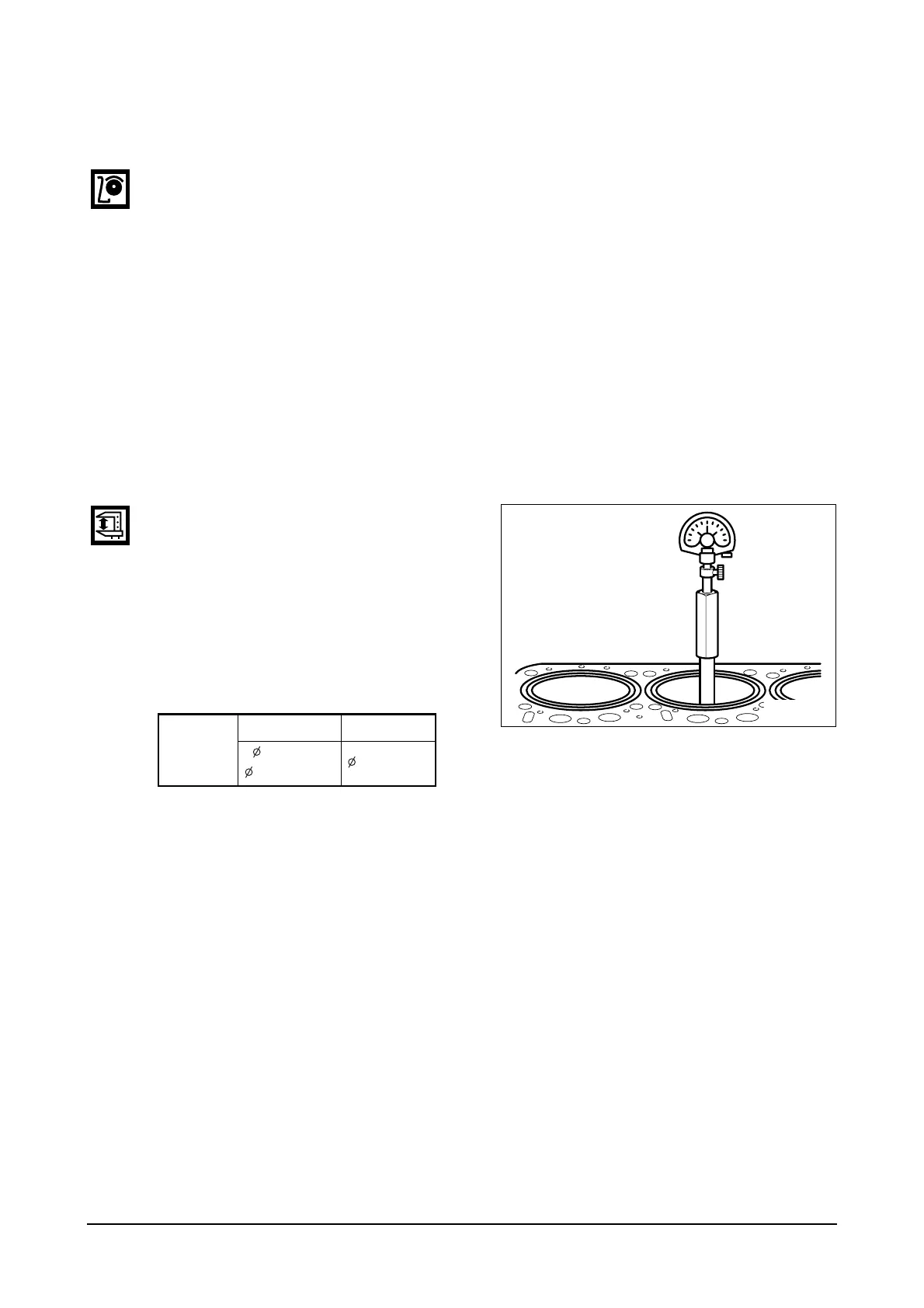

3.2.2. Cylinder liner measurement

z

Assemble the cylinder liner at the

cylinder block and measure inner

diameter at upper, middle, lower that is,

3 steps by 45° interval and calculate the

average values after eliminating the

maximum and minimum values.

z

If the measured values are very close to

the limit value or beyond, replace it

Liner inner

diameter

Standard Limit

127.990 ~

128.010 mm

128.16 mm

EFM2032I

Loading...

Loading...