Maintenance of Major Components

- 147 -

5.8. V-belts

The tension of the V-belts should be checked after every 2,000 hours of operation.

1) Change the V-belts if necessary

If in the case of a multiple belt drive, wear or differing tensions are found, always replace the complete

set of belts.

2) Checking condition

Check V-belts for cracks, oil, overheating and wear.

3) Testing by hand

The tension is correct if the V-belts can be pressed in by about the thickness of the V-belt. (no more

midway between the belt pulleys)

A more precise check of the V-belt tension is possible only by using a V-belt tension tester.

4) Measuring tension

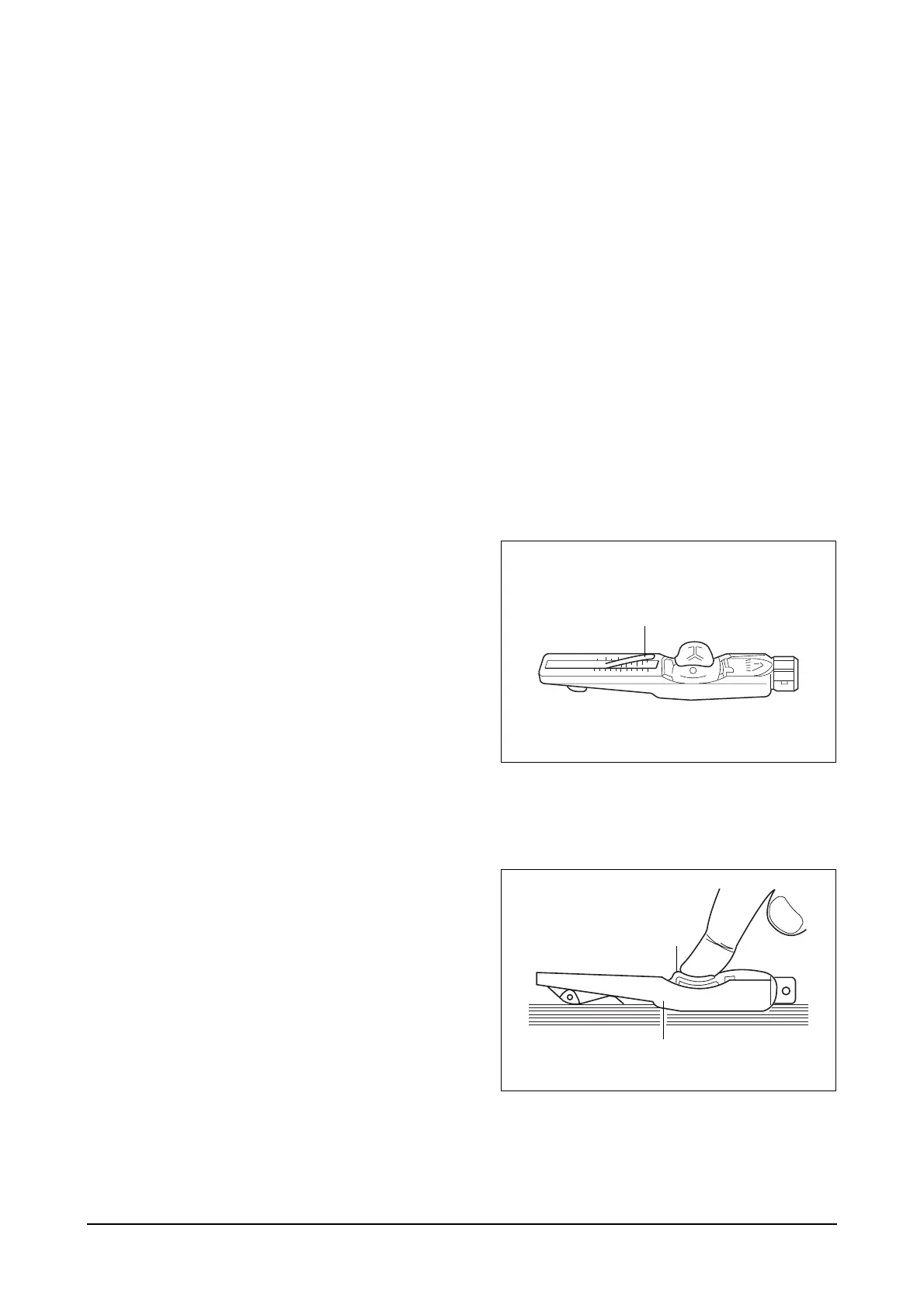

①

Lower indicator arm (1) into the scale.

z

Apply tester to belt at a point

midway between two pulleys so that

edge of contact surface (2) is flush

with the V- belt.

z

Slowly depress pad (3) until the

spring can be heard to disengage.

This will cause the indicator to move

upwards.

If pressure is maintained after the

spring has disengaged a false reading

will be obtained!

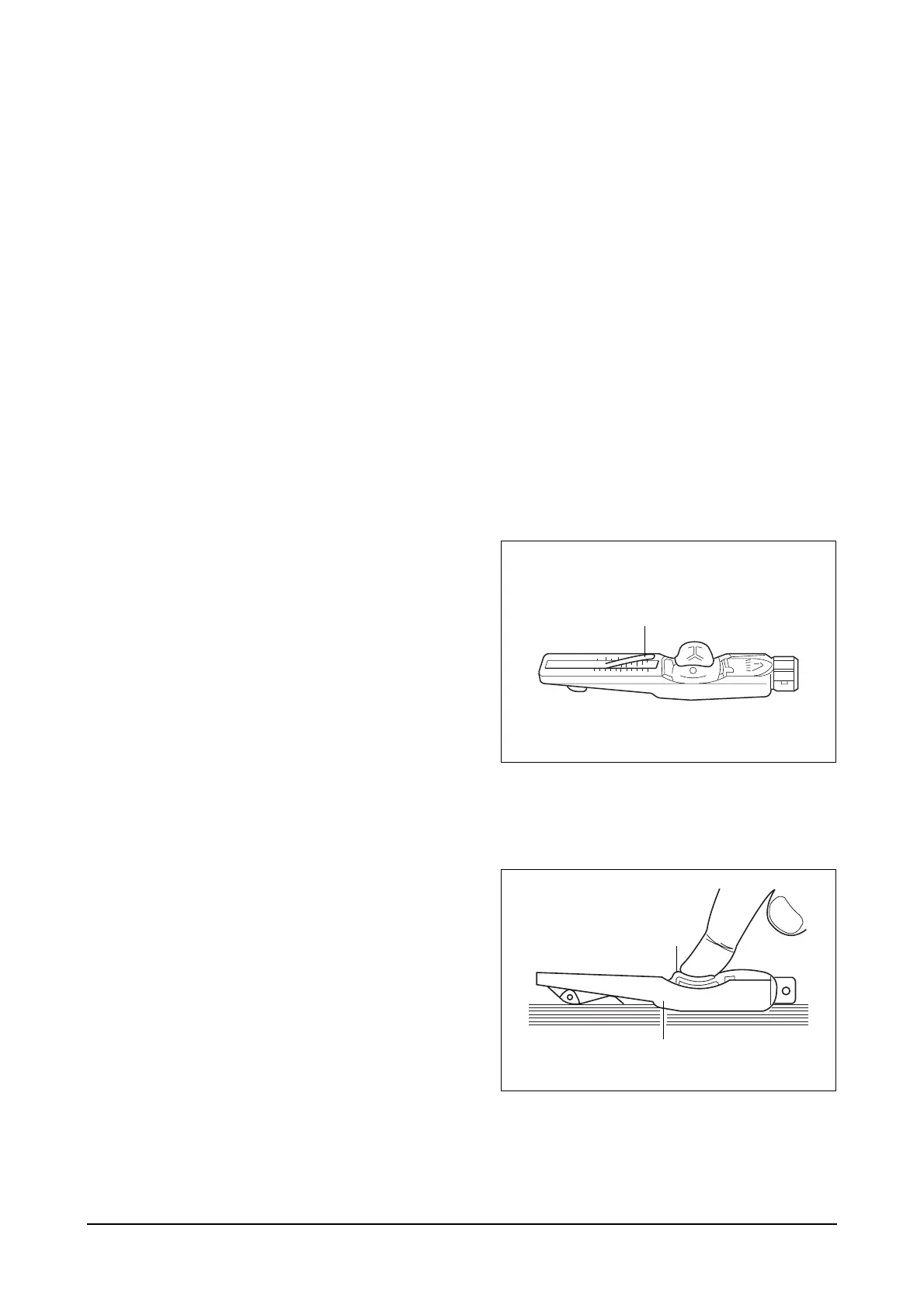

②

Reading of tension

z

Read of the tensioning force of the

belt at the point where the top

surface of the indicator arm (1)

intersects with the scale.

z

Before taking readings make

ensure that the indicator arm

remains in its position.

1

EA6O6011

3

2

EA6O6012

Loading...

Loading...