Maintenance of Major Components

- 137 -

5.4.8. Periodic inspection and maintenance

The turbocharger assembly must be inspected periodically.

1) Revolving state and inspection points of rotor

Inspection on the revolving state of rotor is performed according to abnormal noises. In case of using

an acoustic bar, touch the turbocharger housing with a tip of bar and raise the engine revolution

slowly, Then, in case that high sound is heard by every 2 ~ 3 sec. continuously, for there should be

the possibility to be abnormal metal and rotor, replace or repair the turbocharger.

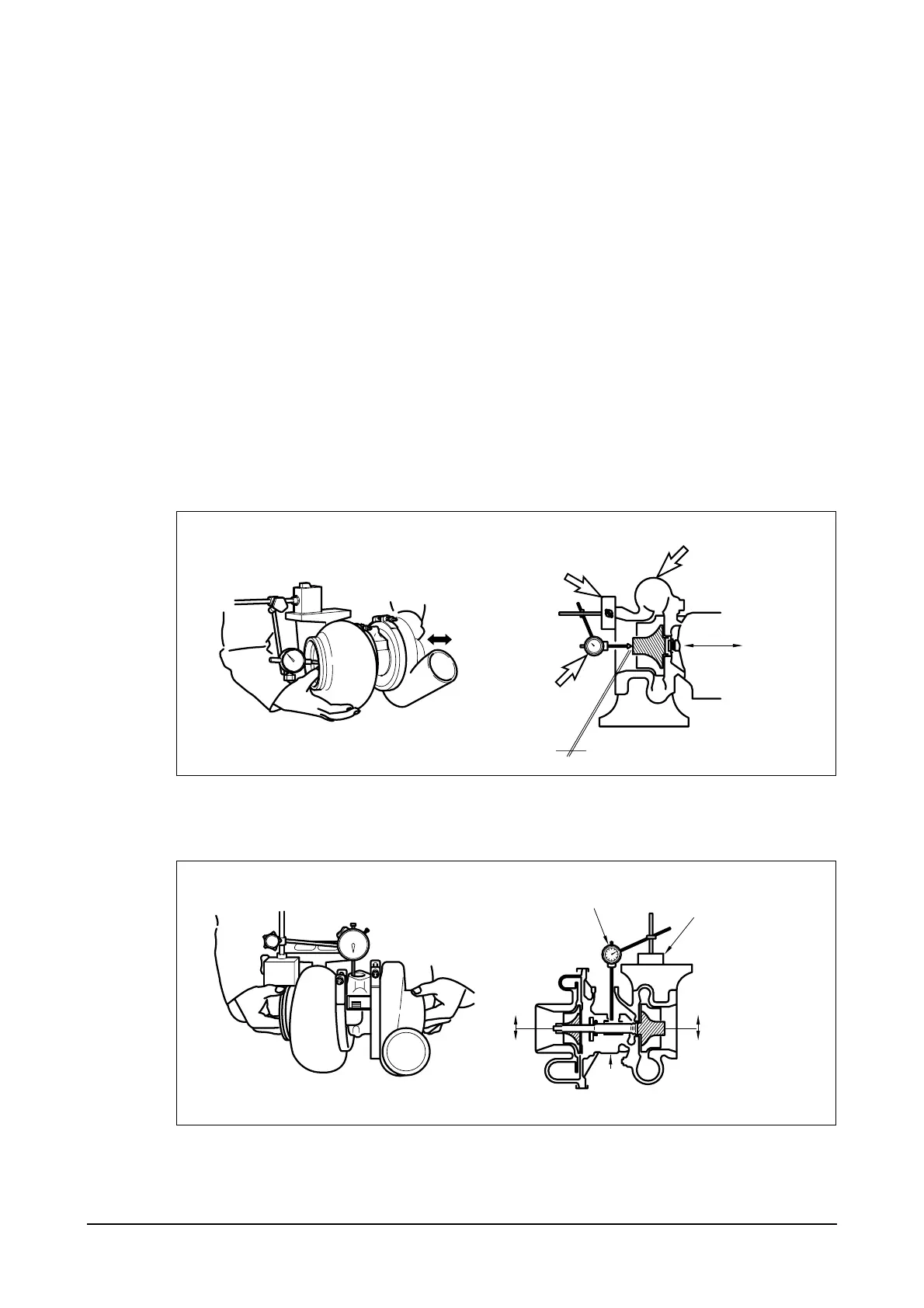

2) End play inspecting points of rotor

Disassemble the turbocharger from the engine and should inspect the end plays in axial and

circumference direction. In case of disassembling the turbocharger, the oil inlet and outlet should

necessarily be sealed with a tape.

a) Axial direction end play

z

Wear limit : 0.20 mm

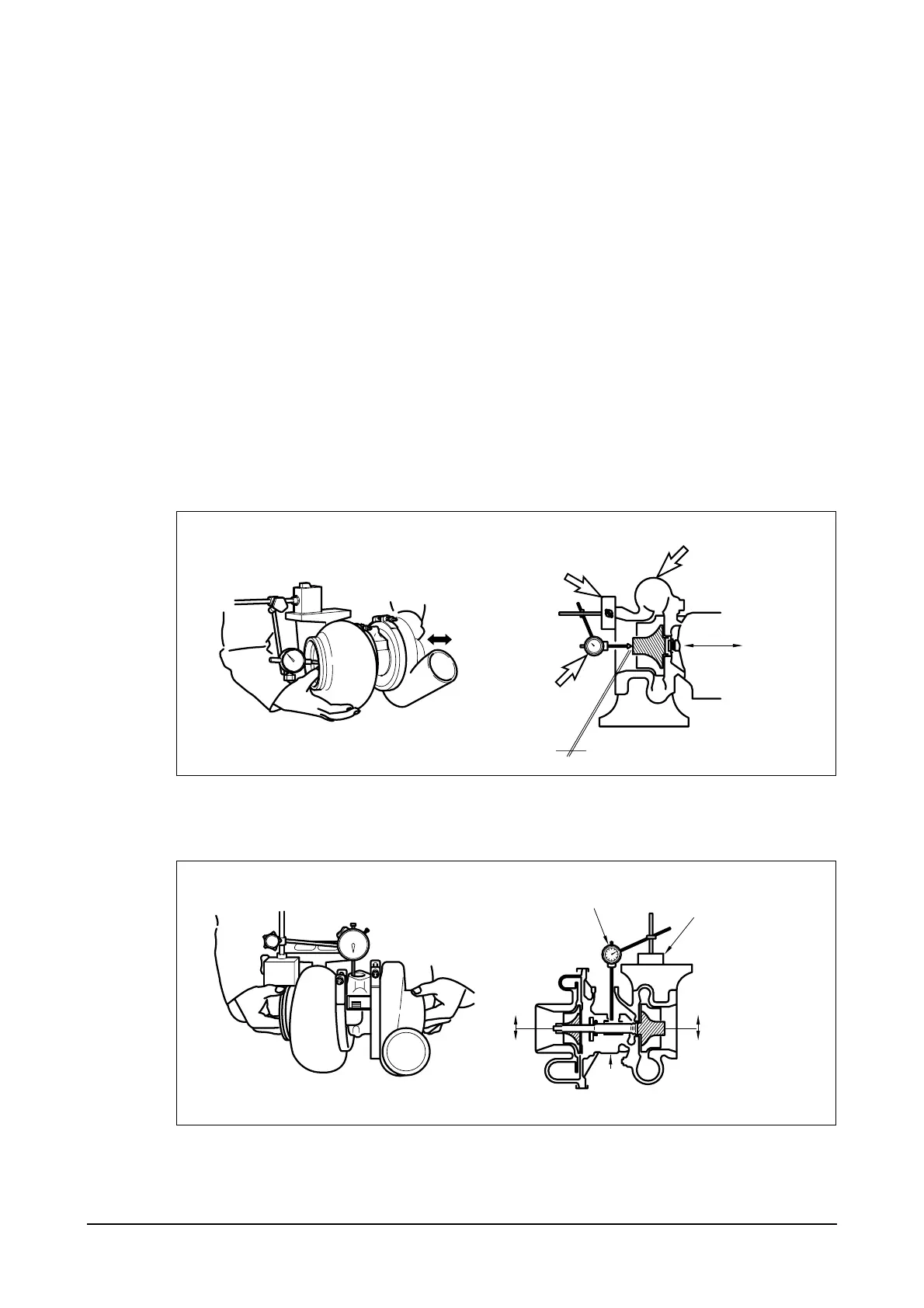

b) Rotor’s circumference direction end play

z

Wear limit : 0.65 mm

c) In case that the end plays to axial and circumference directions, replace or repair the

turbocharger.

Magnet vise

Turbine wheel room

Dial gauge

Shift the

turbine shaft to

axial direction.

Wear limit : 0.20 mm

EFM3004I

EFM3005I

Dial indicator

Magnetic stand

Oil outlet

Oil inlet

Move turbine shaft

at both right and

left sides

simultaneously in

radial direction.

Loading...

Loading...