6 - Maintenance

102

Tightening Bolts and Nuts

When tightening bolts and nuts as a part of periodic service or due to replacement of spare parts, it is important to apply

the correct torque. This will prevent accidents and prolong the lifetime of the parts included in the bolted joints.

If not stated otherwise in this book, please tighten bolts and nuts using the following torques.

*Exceeding this value results in a great risk of deforming the bolt.

±

WARNING! Applying too little torque will result in these risks:

• Bolted joints will rattle and thus fail under fatigue.

• Bolts worn out quickly and thus will not fulfil their design purpose.

• Bolted joints will come loose.

• Accidents caused by assembled parts coming apart due to bolts or nuts failing or falling off.

±

WARNING! Exceeding the maximum torque will result in these risks:

• Damaging or stripping the threads and deforming the bolt.

• Bolt heads will be broken.

• Bolted joints will come loose.

• Accidents caused by assembled parts coming apart due to bolts breaking.

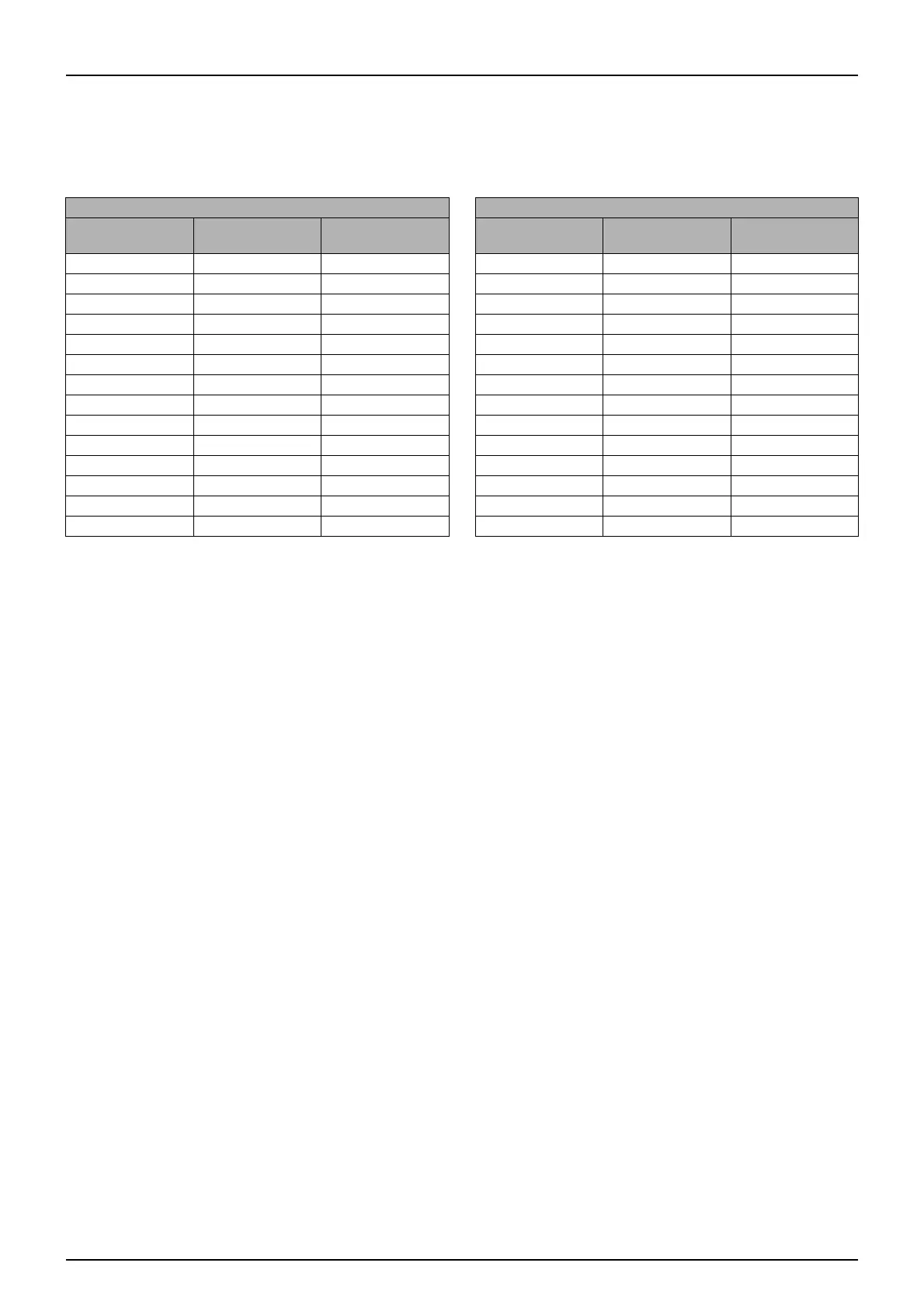

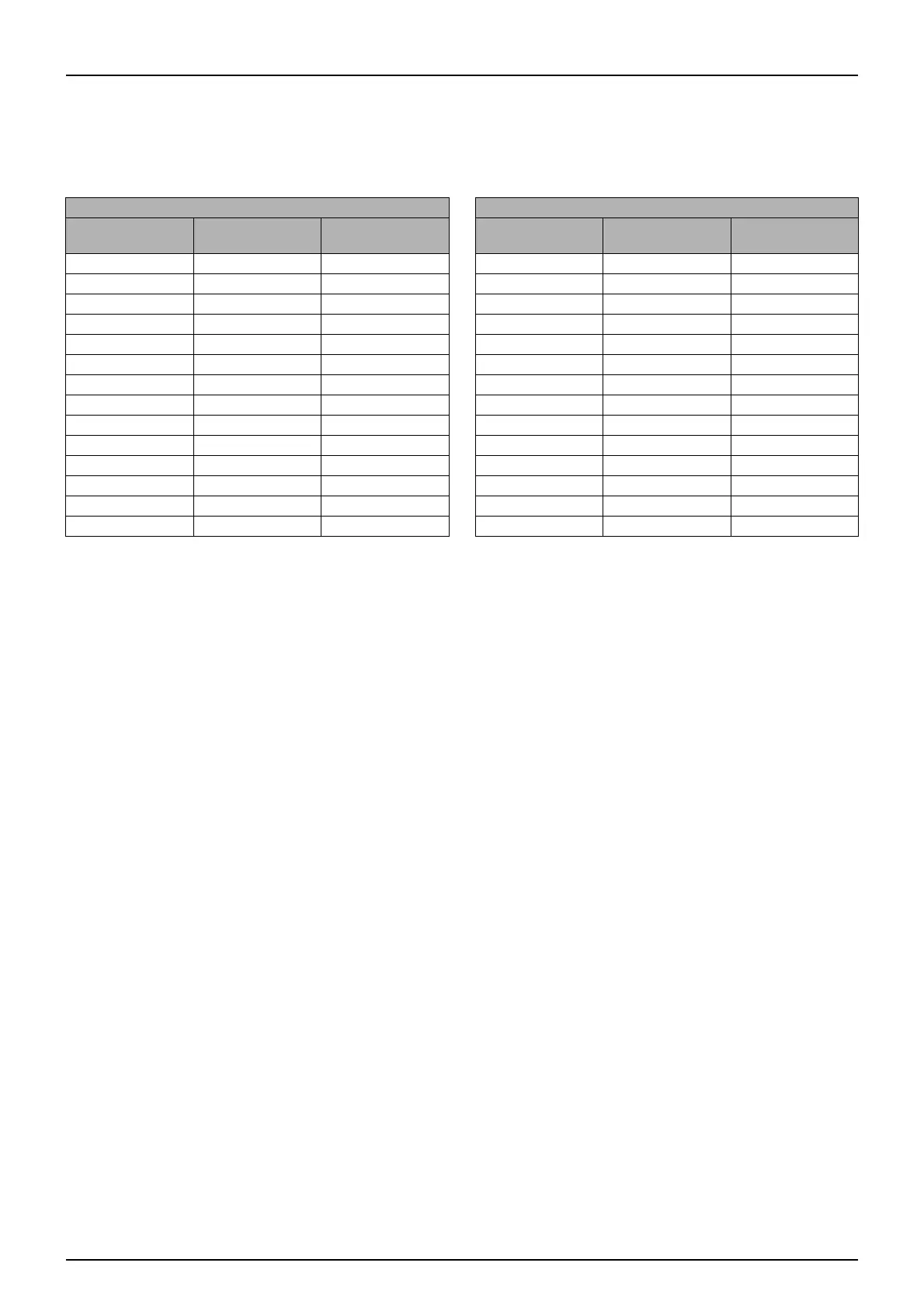

Material: Surface Treated Steel Material: Stainless Steel

Bolt Size (metric) Recommended

Torque (Nm)

Maximum Torque

(Nm)*

Bolt Size (metric) Recommended

Torque (Nm)

Maximum Torque

(Nm)*

M4 2.4 3 M4 1.7 2.1

M5 5 6 M5 3.5 4.2

M6 8 10 M6 5.6 7.0

M8 20 25 M8 14 17.5

M10 39 50 M10 27 35

M12 70 85 M12 49 60

M14 112 140 M14 78 98

M16 180 215 M16 126 151

M18 240 305 M18 168 214

M20 350 435 M20 245 305

M22 490 590 M22 343 413

M24 600 750 M24 420 525

M27 976 1100 M27 683 770

M30 1300 1495 M30 910 1047

Loading...

Loading...