5 - Operation

86

€

DANGER! If the TurboFiller and the transfer hoses are not completely emptied, there is a risk of chemicals flowing back

into the hopper!

8. If the chemical container is empty, it can be rinsed by the “chemical container cleaning device”. Place the container

over the multi-hole nozzle and press the lever to activate container cleaning.

€

DANGER! In order to avoid spray liquid hitting the operator, do not press the lever, unless the multi-hole nozzle is

covered by a container, as spray liquid may otherwise hit the operator!

μ

ATTENTION! The rinsing device uses spray liquid to rinse containers for concentrated chemicals. Before disposal,

always rinse the chemical containers with clean water several times, until they are clean.

9. Flush the TurboFiller with clean water by shifting to suction from the RinseTank or from an external tank. The TurboFiller

suction valve must be open for at least 20 seconds after the rinse water is no longer visible in the hopper, in order to

empty the transfer hoses completely into the MainTank.

μ

ATTENTION! If the suction valve is not shifted to suction from a clean water supply, the hopper rinsing device uses

spray liquid for rinsing the hopper! Cleaning the TurboFiller must always be done, when the spray job is ended, and

together with cleaning the entire sprayer. A cleaning after the last filling, and before spraying, does not ensure a clean

TurboFiller!

10. Close the TurboFiller suction valve, when the hopper has been rinsed. Close the lid.

11. Turn the agitation valve towards “Agitation”.

μ

ATTENTION! If foaming is a problem, reduce the agitation.

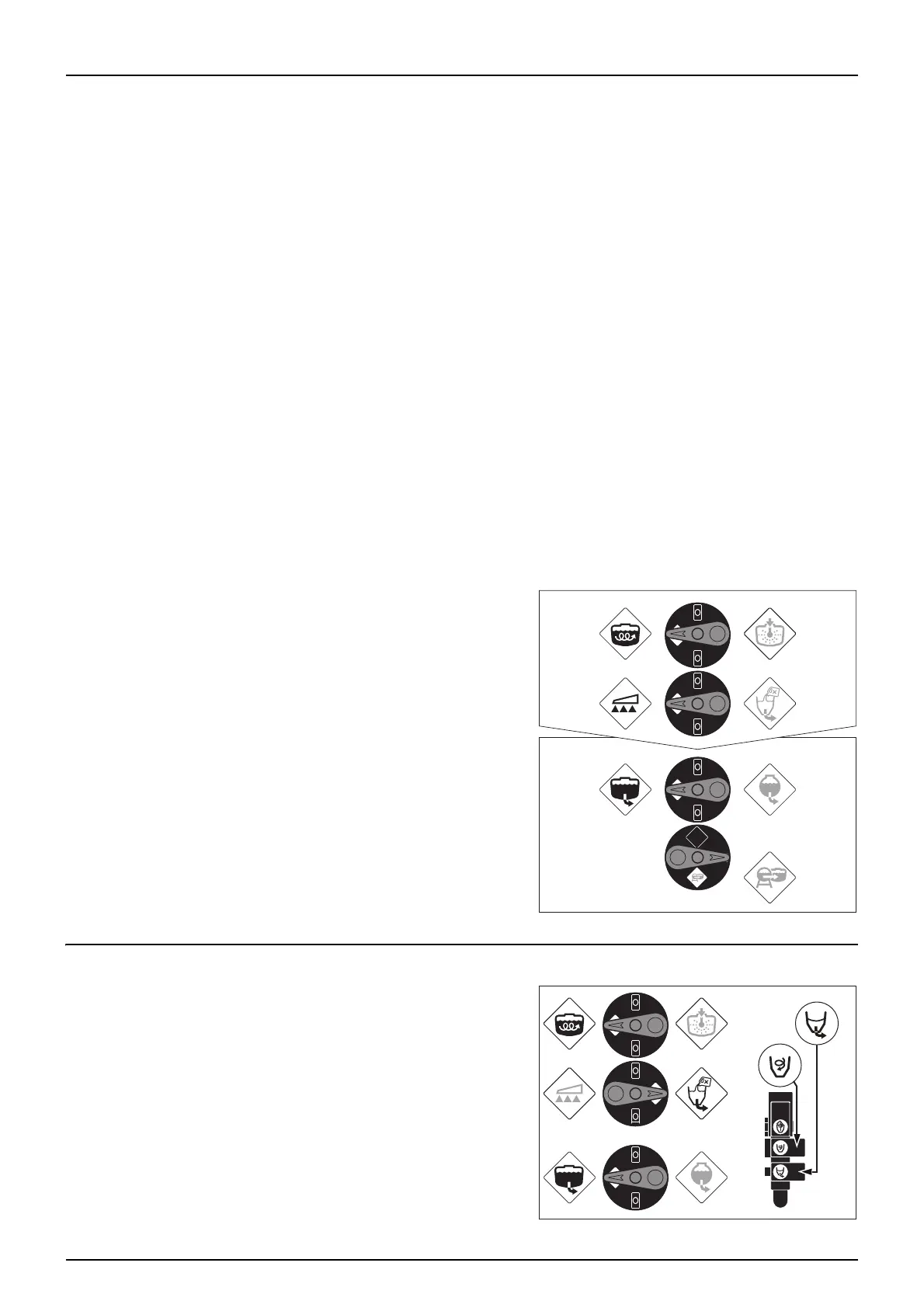

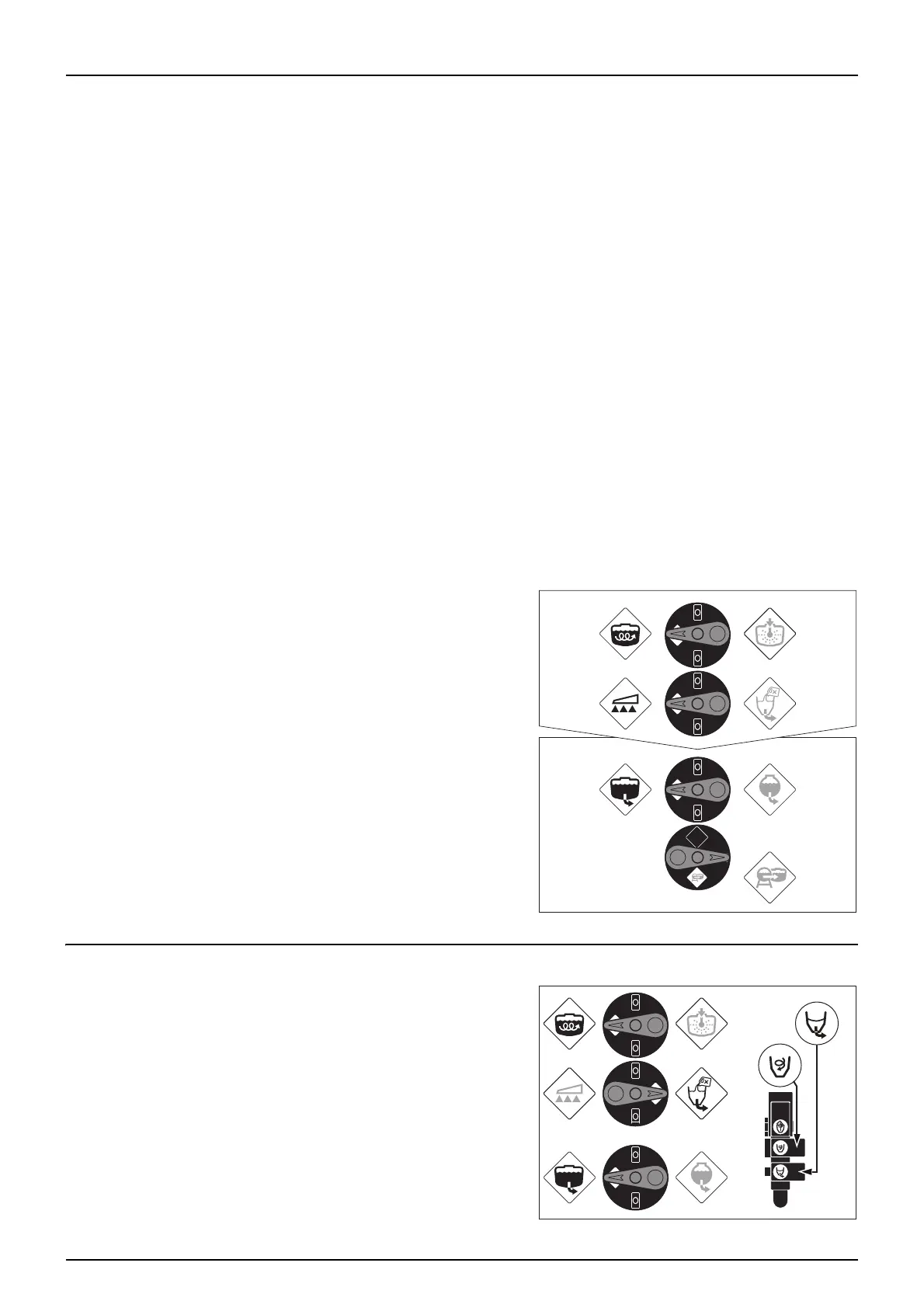

12. When the spray liquid is well agitated, turn the handle for pressure

valve towards “spraying” position. Continue agitation during

spraying of the crop.

Filling Powder Chemicals Using the TurboFiller

1. Fill the MainTank at least 1/2 with water (unless otherwise stated

on the chemical container label). See section “Filling of water”.

2. Turn the handle of the suction valve towards “MainTank”.

3. Turn the pressure valve to“TurboFiller”.

4. Turn the agitation valve towards “agitation” as required:

• A fully open agitation valve will result in very little suction

from the TurboFiller.

• A fully closed agitation valve will result in no agitation, while

the powder is being transferred into the tank, resulting in

poor mixing.

Loading...

Loading...